Production method of zipper heads and device thereof

A production method and technology of a production device are applied in the field of production methods and devices of zipper sliders, which can solve the problems of inability to automatically produce zipper sliders, and achieve the effects of great commercial utilization value, improved efficiency, and improved production accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

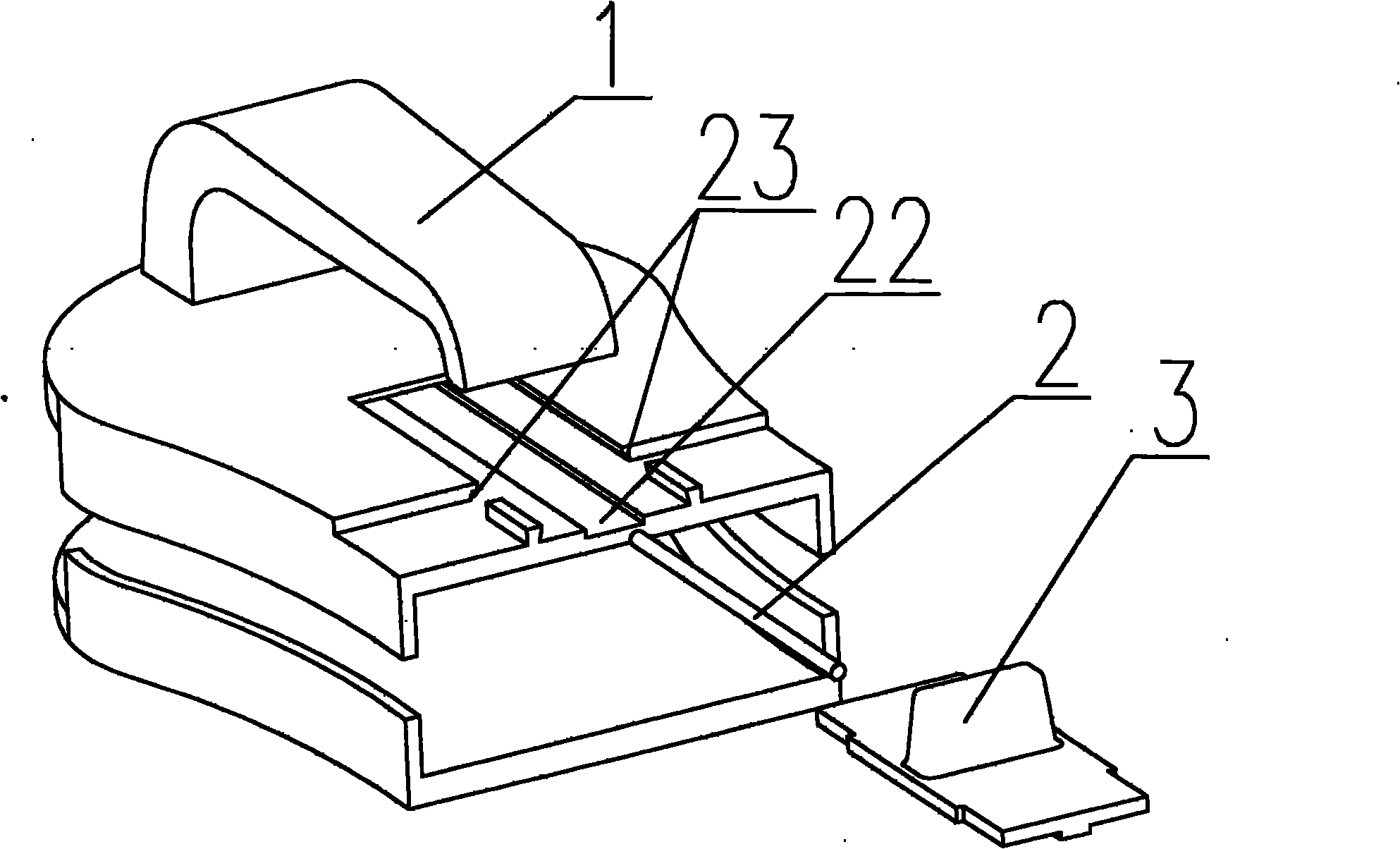

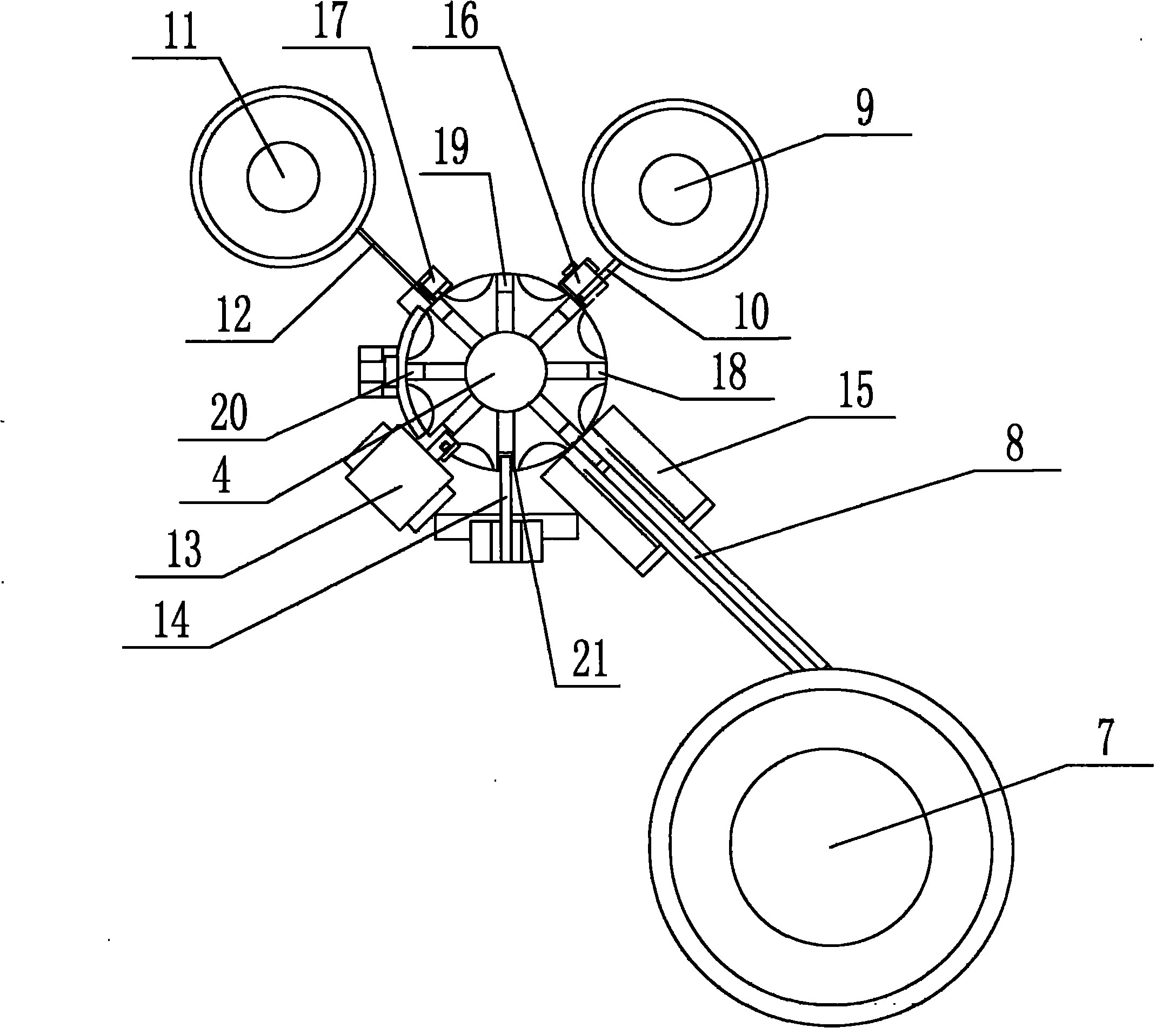

[0028] See attached Figure 1-2 , the steps that the present invention implements are:

[0029] 1) install the single head 1 in the die head 6 on the rotary table 4 through the single head slide rail 8;

[0030] 2) Install the spring 2 in the spring groove 22 in the single head 1 through the spring slide rail 10;

[0031] 3) Install the pin 3 in the pin groove 23 in the single head 1 through the pin slide rail 12;

[0032] 4) Press the rivet at the end of the single head 1 by the pressing device 13;

[0033] 5) Unload the produced zipper sliders from the rotary table 4.

[0034] In the step 1, when the single head 1 is located at the end of the single head slide rail 8, the single head 1 is pushed into the die head 6 on the rotary table 4 by the single head pushing mechanism 15; in the described step 2, the spring 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com