Rotary connecting device for rotating shaft home appliances

A technology of rotary connection and home appliances, applied in the direction of electromechanical devices, electromechanical transmission devices, electrical components, etc., can solve the problems of short service life, high noise, high failure rate, etc., and achieve long service life, low centering error and low failure rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

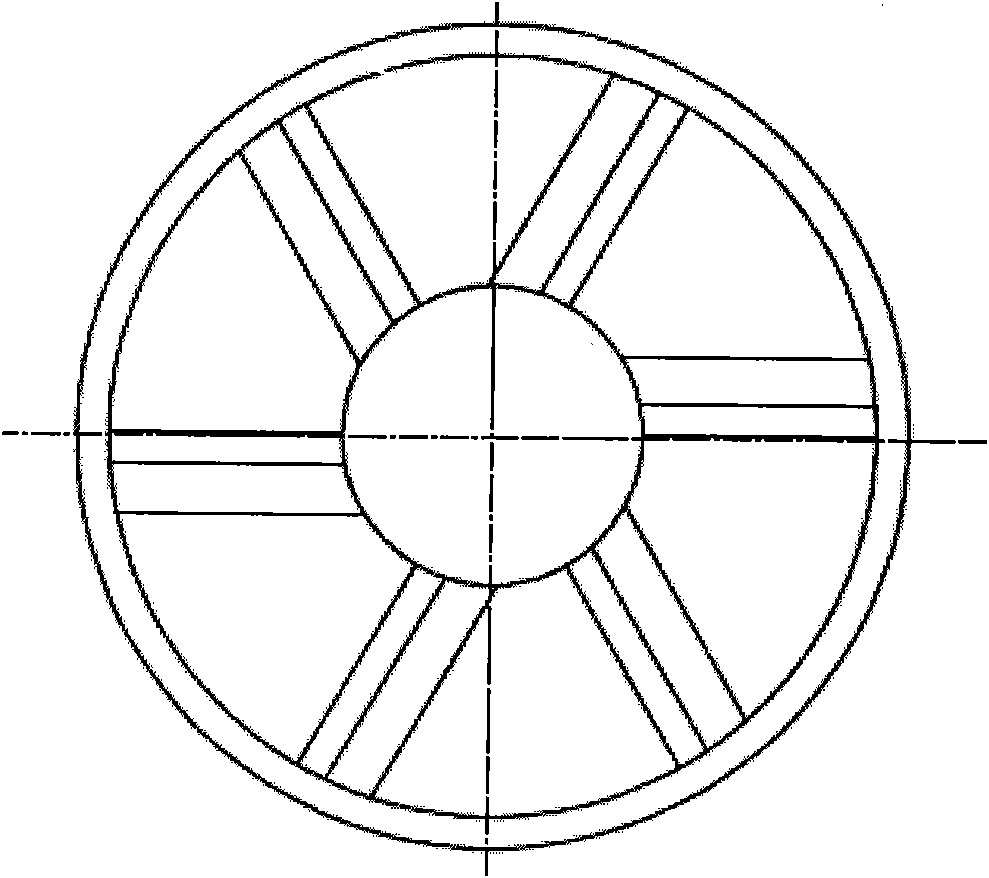

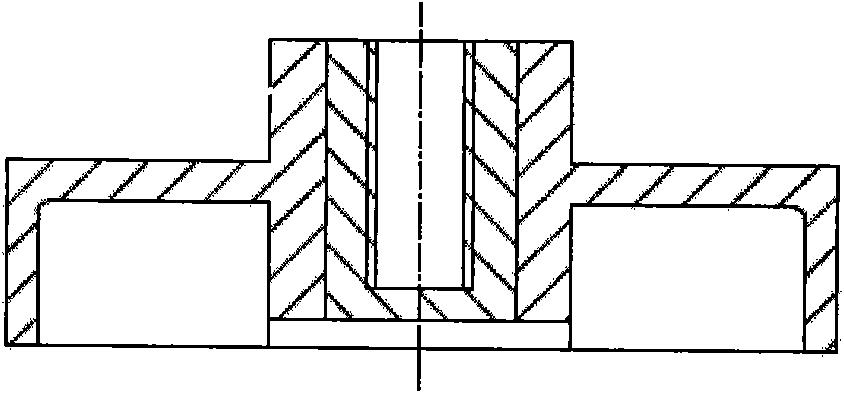

[0027] combine Figure 5 The rotary connection device of the rotating shaft type home appliance includes a motor output shaft 6 and a drive carrier shaft 7 that drives the carrier to rotate, and also includes a permanent magnet rotor 1 and a cylindrical metal conductor 3. The permanent magnet rotor 1 is fixedly connected to the motor output shaft 6 and is cylindrical. The metal conductor 3 is fixedly connected to the drive carrier shaft 7, the permanent magnet rotor 1 is located in the cylindrical metal conductor 3, the two can rotate relative to each other, and there is a gap between the side wall of the permanent magnet rotor 1 and the inner wall of the cylindrical metal conductor 3 , There is a gap between the top of the permanent magnet rotor 1 and the bottom of the cylindrical metal conductor 3 .

[0028] The permanent magnet rotor 1 is a cylindrical solid permanent magnet with a groove at the top, and a protrusion is arranged at the bottom end inside the cylindrical meta...

Embodiment 2

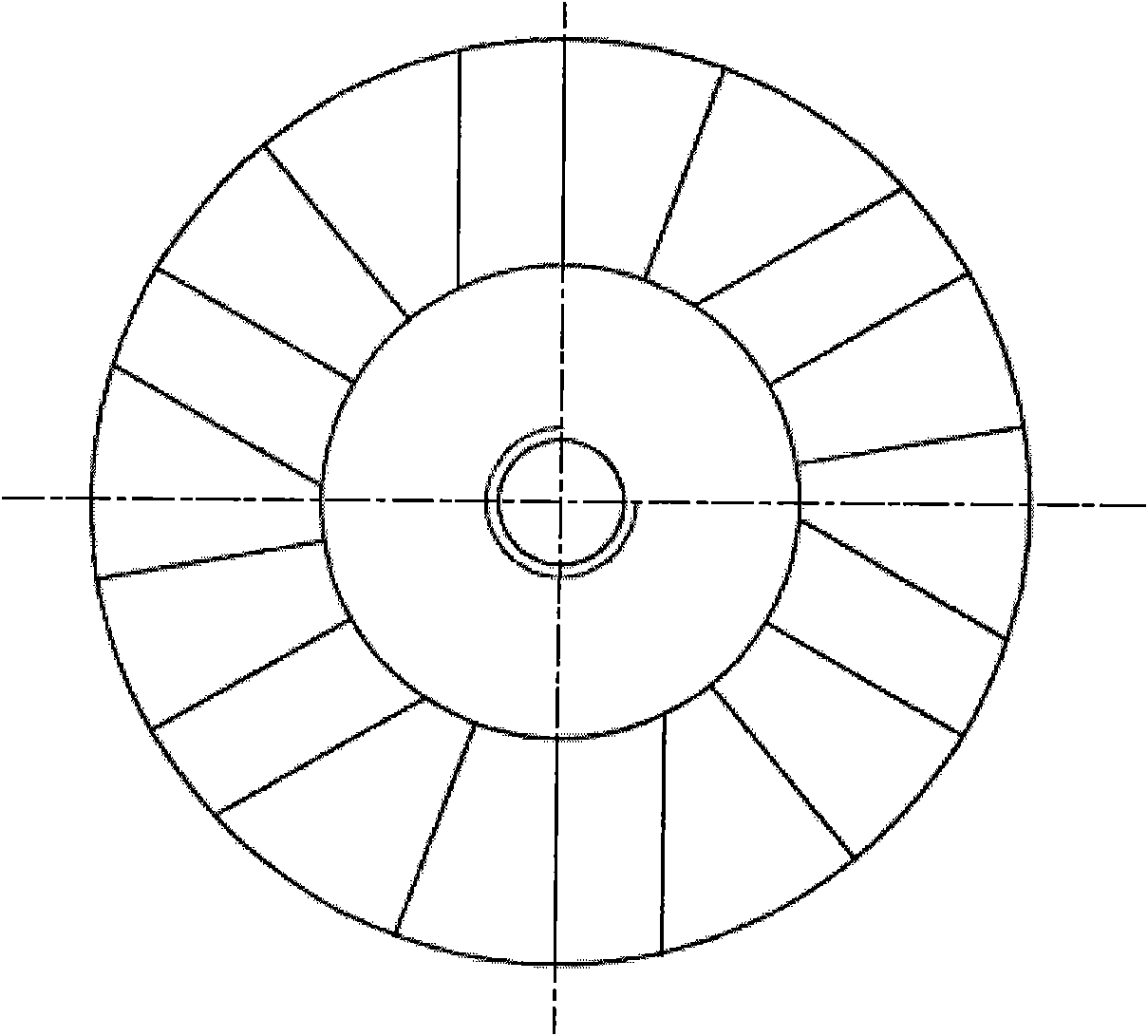

[0031] combine Image 6 The rotary connection device of the rotating shaft type home appliance includes a motor output shaft 6 and a drive carrier shaft 7 that drives the carrier to rotate, and also includes a permanent magnet rotor 1 and a cylindrical metal conductor 3. The permanent magnet rotor 1 is fixedly connected to the motor output shaft 6 and is cylindrical. The metal conductor 3 is fixedly connected to the drive carrier shaft 7, the permanent magnet rotor 1 is located in the cylindrical metal conductor 3, the two can rotate relative to each other, and there is a gap between the side wall of the permanent magnet rotor 1 and the inner wall of the cylindrical metal conductor 3 , There is a gap between the top of the permanent magnet rotor 1 and the bottom of the cylindrical metal conductor 3 .

[0032] The permanent magnet rotor 1 is a permanent magnet embedded with metal aluminum 8 , that is, the inner center of the permanent magnet is embedded with metal aluminum 8 . ...

Embodiment 3

[0036] combine Figure 7 The rotary connection device for rotating shaft household appliances includes a motor output shaft 6 and a drive carrier shaft 7 that drives the carrier to rotate, and also includes a permanent magnet rotor 1 and a cylindrical metal conductor 3. The permanent magnet rotor 1 is fixedly connected to the drive carrier shaft 7, and the cylindrical metal conductor The conductor 3 is fixedly connected to the motor output shaft 6, the permanent magnet rotor 1 is located in the cylindrical metal conductor 3, the two can rotate relative to each other, there is a gap between the side wall of the permanent magnet rotor 1 and the inner wall of the cylindrical metal conductor 3, There is a gap between the top of the permanent magnet rotor 1 and the bottom of the cylindrical metal conductor 3 .

[0037] The permanent magnet rotor 1 is a cylindrical solid permanent magnet with a groove at the top, and a protrusion is arranged at the bottom end inside the cylindrical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com