Seamless track stress dispersion rail collision device

A stress-releasing, seamless line technology, applied in the directions of roads, tracks, laying tracks, etc., can solve the problems of inability to directionally reduce stress peaks, the effect is not ideal, and the hydraulic rail bumper has not achieved the effect of on-site use. The effect of conveying and transferring and sliding resistance is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

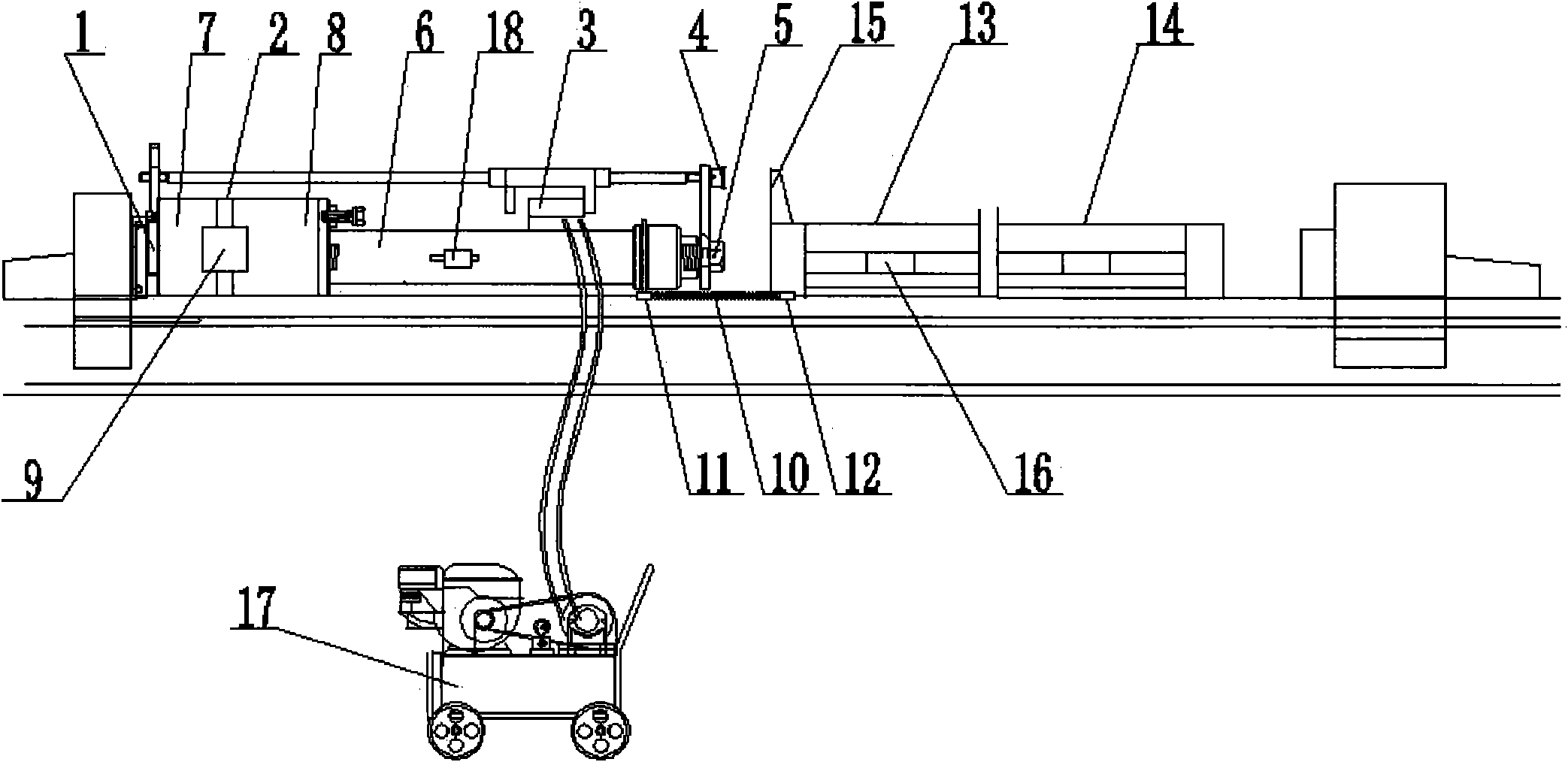

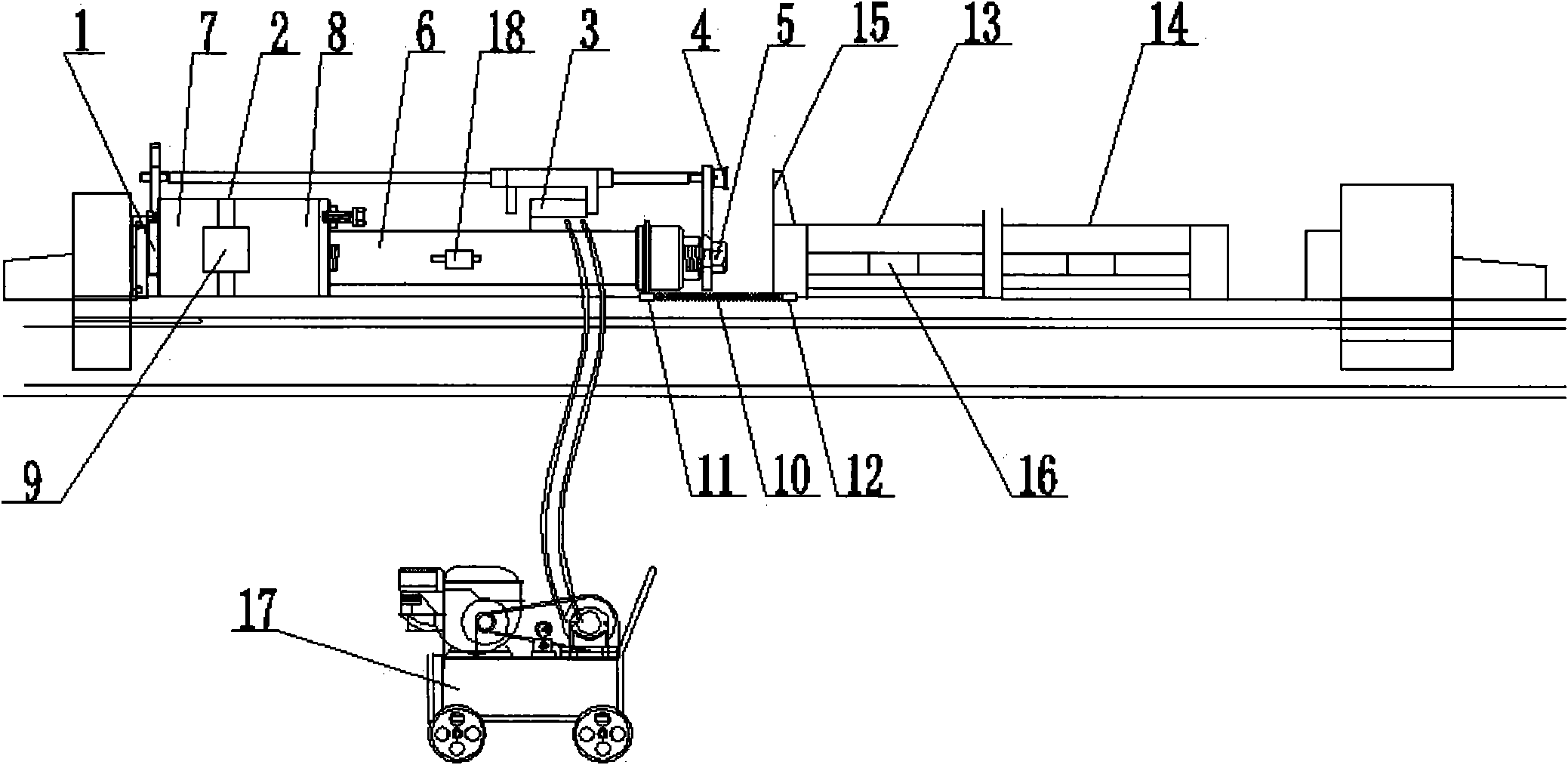

[0025] Embodiment 1. The seamless line stress relief and rail collision device includes a hydraulic pump device 17, an impact device and a rail collision device. It is characterized in that: the hydraulic pump device 17 communicates with the impact device through the oil inlet and oil outlet, and the impact device One end of the impact device is fixed on the rail, and the other end of the impact device is provided with a punch 5, and the punch 5 collides with the rail collision device.

Embodiment 2

[0026] Embodiment 2, the seamless line stress relief and rail collision device, wherein: the accumulator 2 of the impact device is installed on the machine base 1, and the trigger 4 that can be movably contacted with the rail collision device is connected to the reversing valve 3 through the connecting piece The accumulator 2 is connected with the impact cylinder 6 through the reversing valve 3 set on the oil circuit. All the other are with embodiment 1.

Embodiment 3

[0027] Embodiment 3, seamless line stress release rail collision device, wherein: the impact device includes an accumulator 2, a reversing valve 3, and an impact cylinder 6; the accumulator 2 is divided into a high-pressure air chamber 7 and a hydraulic chamber 8, and the high-pressure air chamber The chamber 7 and the hydraulic chamber 8 are connected through a piston 9; the hydraulic chamber 8 communicates with one end of the impact cylinder 6, and the other end of the impact cylinder 6 is connected with the punch 5. All the other are with embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com