Preparation method of salted vegetable concentrated liquid

A technology for salted vegetables and concentrated liquid is applied in the field of preparation of salted vegetable concentrated liquid, which can solve the problem that the salted vegetable fermentation liquid cannot be effectively recycled, and can solve the problem of ineffective recycling, improve the utilization rate, and improve the processing capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

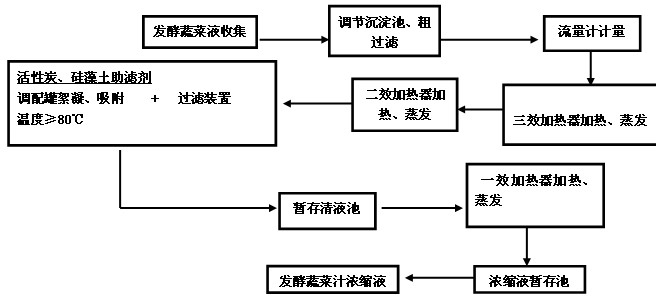

[0019] Embodiment 1: as figure 1 Shown, a kind of preparation method of salted vegetables concentrated liquid comprises the following steps:

[0020] A. Collect fermented mature salted vegetable fermentation liquid in the adjustment sedimentation tank, and carry out coarse filtration through the filter screen at the bottom of the adjustment sedimentation tank. The mesh diameter of the filter screen is 0.10mm, and the mesh width is 0.2mm. initial clarification of the liquid;

[0021] B. Send the coarsely filtered fermented liquid to a three-effect evaporator through a flowmeter, heat and evaporate under the conditions of a vacuum of 0.08Mpa and a boiling point of 50-55°C;

[0022] C, the salted vegetable fermented liquid treated in step B is sent to the second-effect evaporation device, heated and evaporated under the conditions of vacuum degree 0.06Mpa and 80-85°C;

[0023] D. The salted vegetable fermentation liquid treated in step C is sent to activated carbon and diatomit...

Embodiment 2

[0025] Embodiment 2: as figure 1 Shown, a kind of preparation method of salted vegetables concentrated liquid comprises the following steps:

[0026] A. Collect fermented mature salted vegetable fermentation liquid in the regulating sedimentation tank, and carry out coarse filtration through the filter screen at the bottom of the regulating sedimentation tank. The mesh diameter of the filter screen is 0.40mm, and the mesh width is 0.8mm. initial clarification of the liquid;

[0027] B. Send the coarsely filtered fermented liquid to a three-effect evaporator through a flowmeter, heat and evaporate under the conditions of a vacuum of 0.08Mpa and a boiling point of 50-55°C;

[0028] C, the salted vegetable fermented liquid treated in step B is sent to the second-effect evaporation device, heated and evaporated under the conditions of vacuum degree 0.06Mpa and 80-85°C;

[0029] D. The salted vegetable fermentation liquid treated in step C is sent to activated carbon and diatomit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com