Repeatedly packaging lens construction and production method thereof

A production method and lens technology, applied in installation, optics, instruments, etc., can solve the problems of inconvenient operation of inspectors, low module inspection efficiency, and unfavorable mass production, and achieve simplified production and inspection processes, simple structure, The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

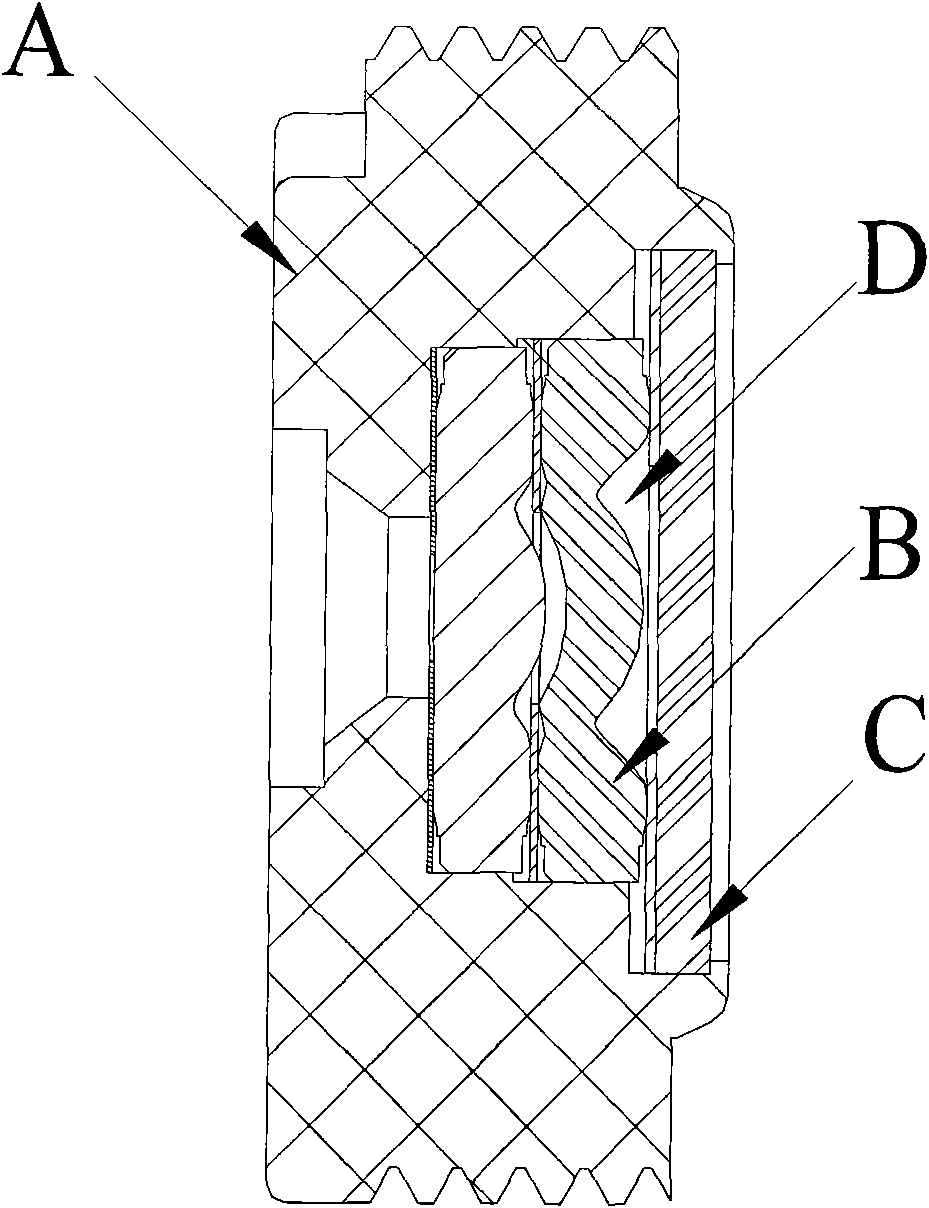

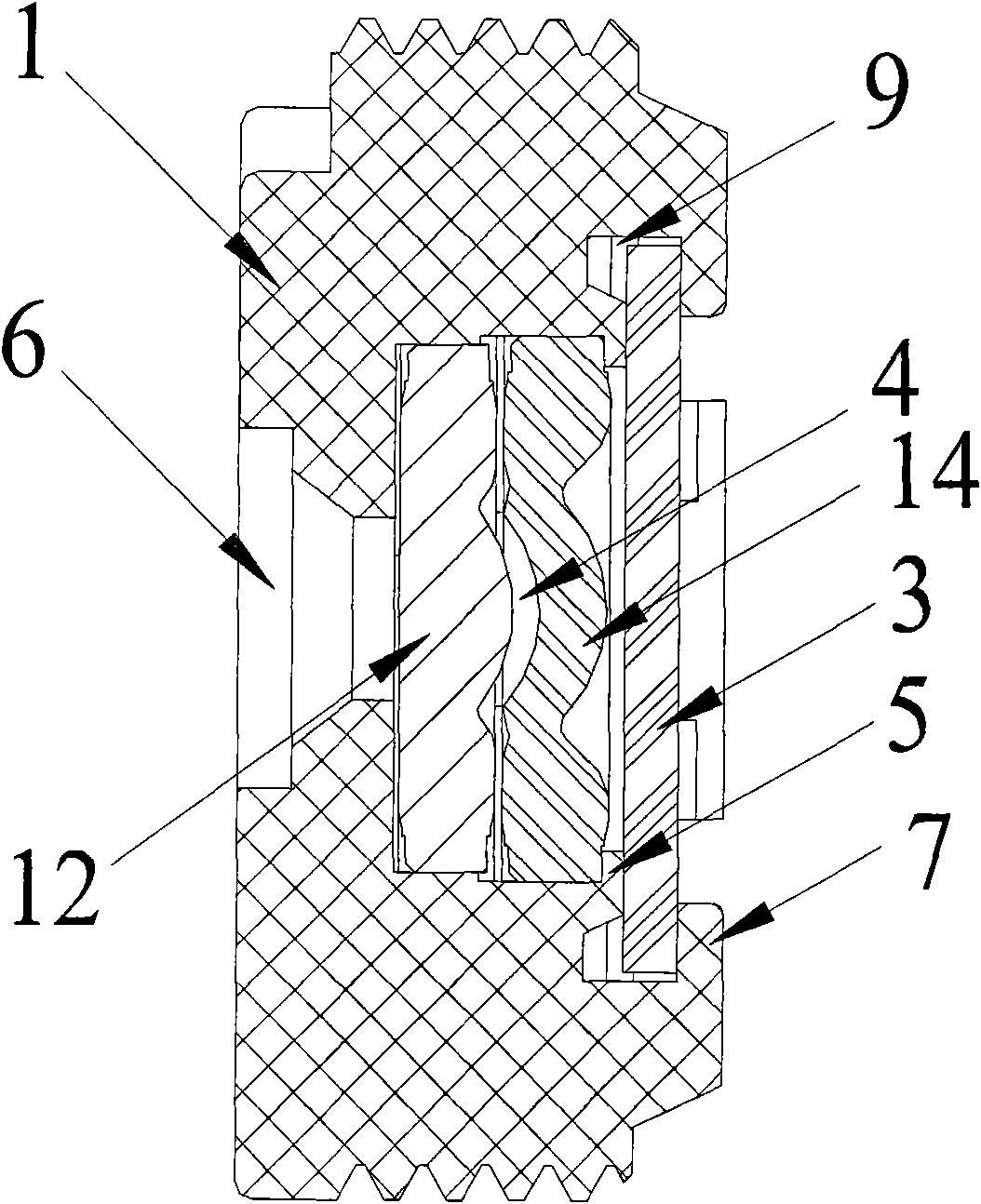

[0027] like Figure 2 to Figure 5 As shown, the present invention includes a lens barrel 1, a lens group 2 and an optical filter 3, wherein, the inner cavity of the lens barrel 1 is sequentially provided with a coaxial and interconnected optical hole 6, a lens space 4 and an optical filter space 9 , the lens group 2 is installed in the lens space 4 , the bottom of the lens space 4 protrudes toward the axis with a wrapping 5 enclosing the lens group 2 , and the optical filter 3 is installed in the optical filter space 9 .

[0028] In the present invention, the lens group and the optical filter are packaged separately, the structure is simple, and the production cost is low; the production personnel can first package and test the lens group. The detection method is used for detection, and then the filter is packaged to obtain the finished product. This greatly simplifies the production and testing process and improves work efficiency.

[0029] The bottom of the above-mentioned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com