High-speed and low-noise precise ball screw pair

A technology of ball screw pair and ball screw, which is applied in the direction of spring/shock absorber, vibration suppression adjustment, belt/chain/gear, etc. It can solve problems such as uneven transition, large angle at the corner of the spiral groove, and impact. To achieve the effect of solving noise, overcoming shock and vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described in further detail below in conjunction with accompanying drawing:

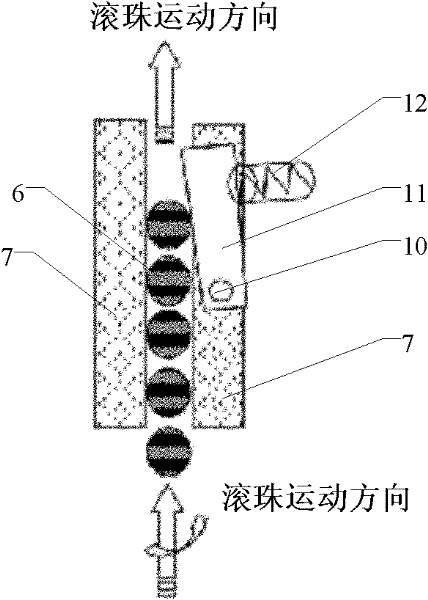

[0015] refer to figure 1 , The new high-speed precision ball screw pair consists of a ball screw 1, a ball nut 3, a ball 6, an elastic buffer 4, an elastic return damper 5, a nut shell 8 and a sealing ring 9. A ball nut 3 is sleeved on the ball screw 1 , a raceway 2 is arranged on the outer circle of the ball screw 1 and the inner circle of the ball nut 3 , and a ball 5 is arranged in the raceway 2 . Both ends of the ball nut 3 are provided with reverser grooves, and elastic buffers 4 , elastic return dampers 5 and ball return passages 7 through which are respectively arranged in each reverser groove. During the movement of the ball screw pair, the balls 6 respectively pass through the raceway 2 between the ball screw 1 and the ball nut 3, the elastic buffer 4, the elastic return damper 5 and the through ball return channel 7 to reach the ball nut 3 The elastic buffe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com