Variable-sweeping plane disc sweeper of road sweeping truck

A road cleaning and flat technology, applied in road cleaning, cleaning methods, construction, etc., can solve the problems of large cleaning resistance, ups and downs, and high use cost, and achieve the effect of reducing frictional resistance, high cleanliness, and material saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

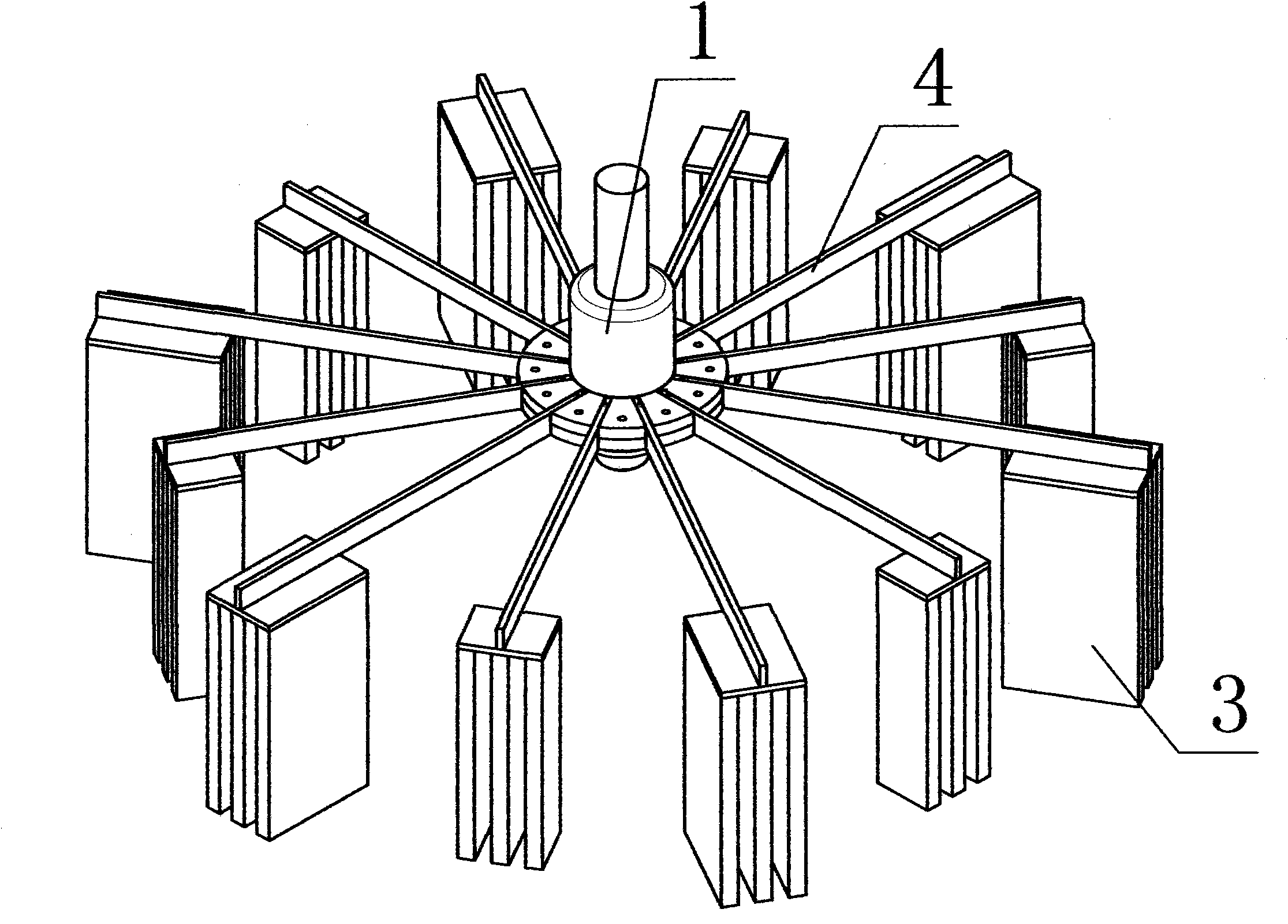

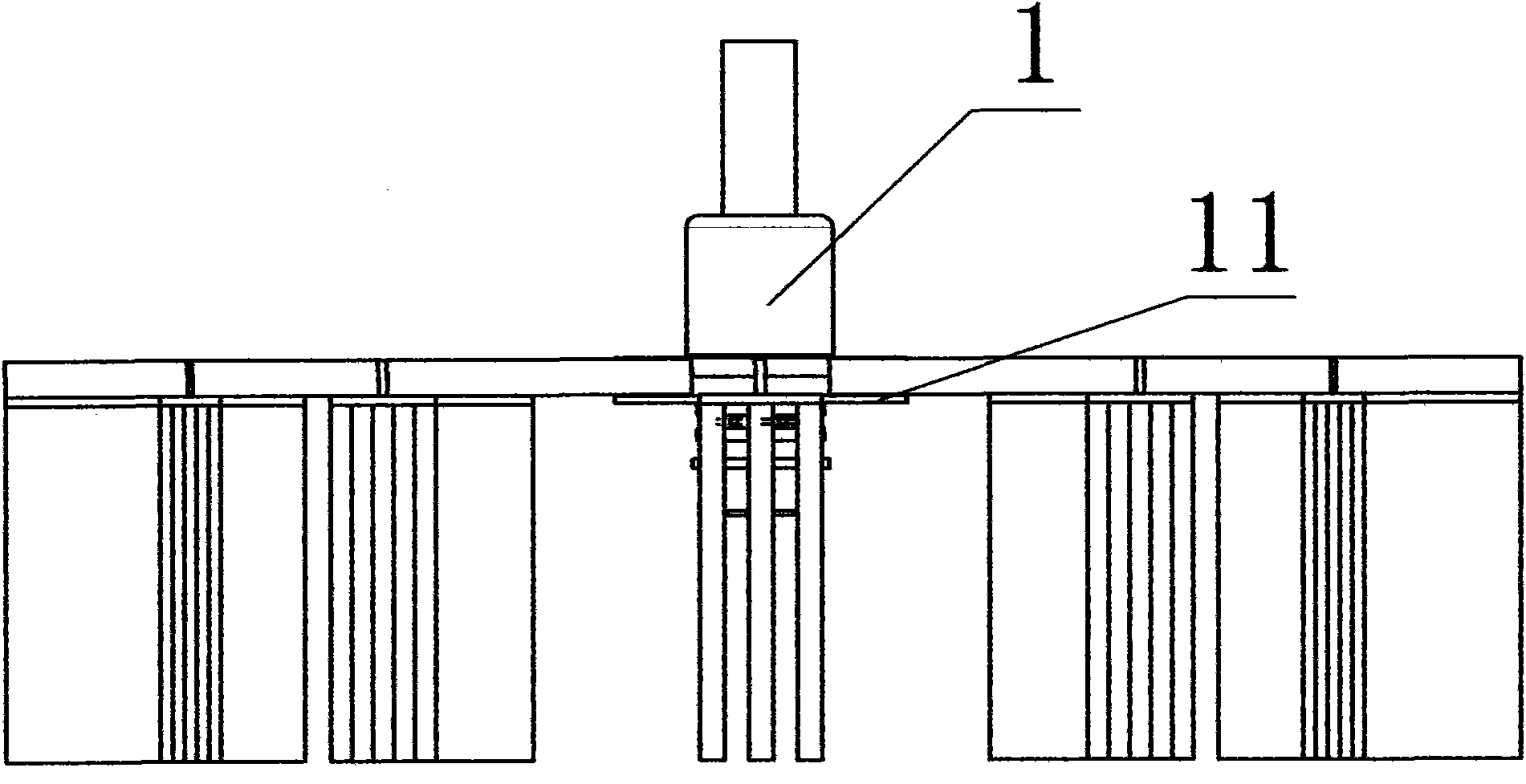

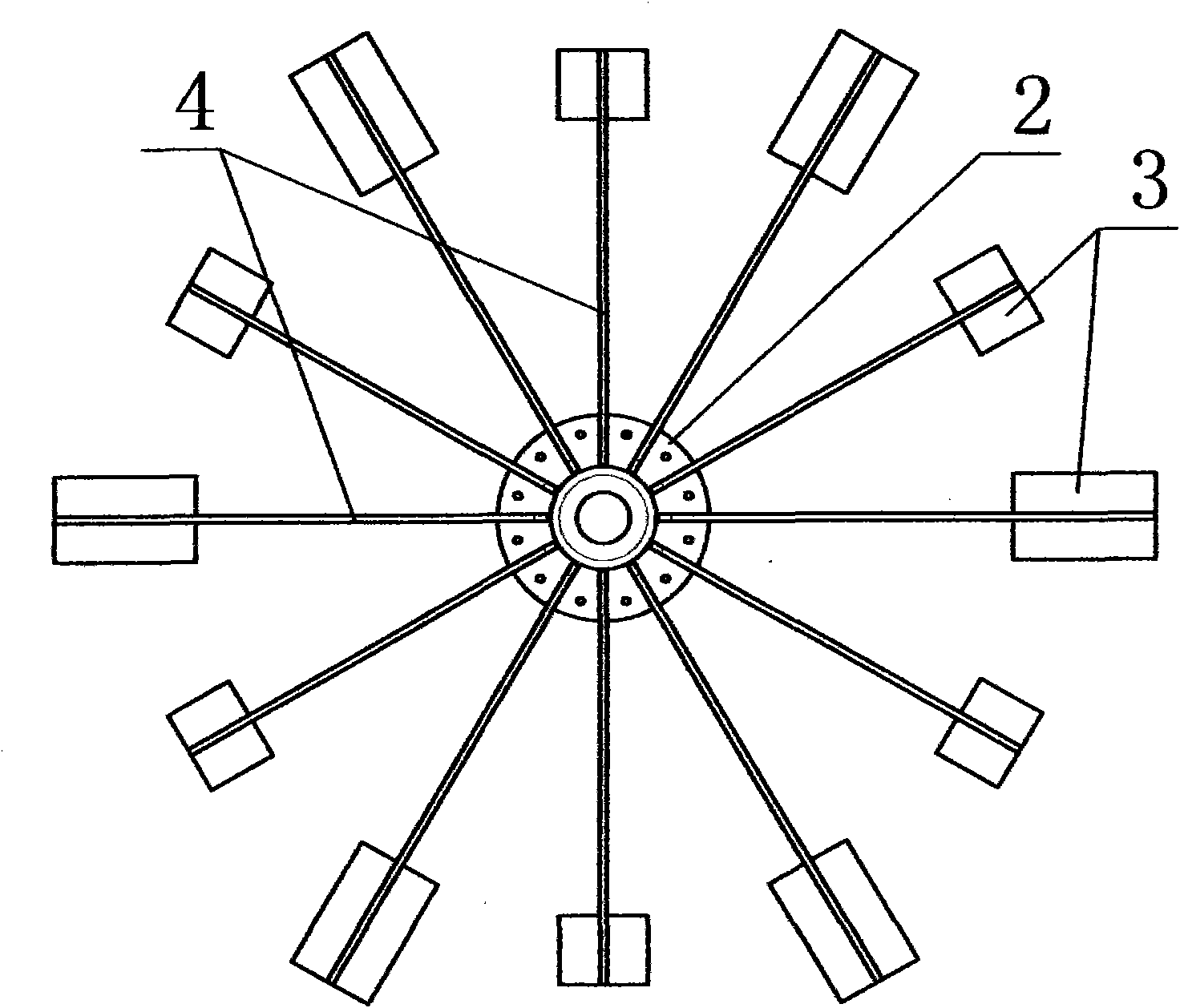

[0050] Such as figure 1 , Picture 1-1 with Figure 1-2 As shown, the variable sweeping plane of the road sweeper of the present invention is composed of a motor 1, a turntable 2 and a broom, and the broom is composed of a broom handle 4 and a broom brush 3. The turntable can be composed of upper and lower plates. The turntable is superimposed. When the motor does not directly drive the turntable to rotate, such as through a transmission device, the turntable has a turntable shaft at this time. When the motor directly drives the turntable to rotate, there is no need to pass the transmission device. The turntable shaft is the motor shaft of the motor. At this time: the rotor of the motor 1 is fixedly connected to the turntable, and a built-in broom shaft 13 (see Figure 4 ) Of the broom shaft slot 6 (see image 3 ), on the plane of the turntable is provided with a plurality of broom shaft grooves 6 that open from the outer periphery of the circumference and pass through the broom ...

Embodiment 2

[0052] Such as figure 1 , Picture 1-1 with Figure 1-2 As shown, the variable cleaning plane disc sweep of the road sweeper of the present invention includes a motor 1, a turntable 2 and a broom, etc. The broom is composed of a broom handle 4 and a broom brush 3, and the turntable 2 can be an upper and lower turntable. When the motor does not directly drive the turntable to rotate, such as through a transmission device, the turntable has a turntable shaft. When the motor directly drives the turntable to rotate, there is no need to pass through the transmission device. The turntable of the turntable at this time The shaft is the motor shaft of the motor. At this time: the rotor of the motor 1 is fixedly connected to the turntable, and a built-in broom shaft 13 (see Figure 4 ) Of the broom shaft slot 6 (see image 3 ), on the plane of the turntable are provided with a plurality of broom shaft grooves 6 that open from the outside of the circumference and pass through the broom sha...

Embodiment 3

[0054] Such as Figure 14 , Figure 14-1 , Figure 14-2 with Figure 14-3 As shown, the variable cleaning plane of the road sweeper of the present invention is composed of a motor, a turntable 2 and a broom. The broom is composed of a broom handle 4 and a broom brush 3, one end of an inverted L-shaped roller bracket 15 It is fixedly connected to the upper part of the broom handle 4, and the other end of the inverted L-shaped roller bracket 15 is rotatably connected with the supporting roller 10. The broom with this structure is referred to as a broom with an inverted L-shaped roller bracket broom support roller in this manual. The turntable can be made by superimposing the upper and lower turntables. At this time, the turntable is installed under the broom roller support plate 9. When the motor does not directly drive the turntable to rotate, such as through a transmission device, then the turntable has a turntable shaft and the broom roller supports The disk 9 and the turntabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com