Upper leather ring rack for drafting device of spinning frame

A drafting device and spinning frame technology, applied in the field of the upper aprons, can solve the problems of the amplitude of the ascending and descending movements being large, and achieve the effect of avoiding deflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

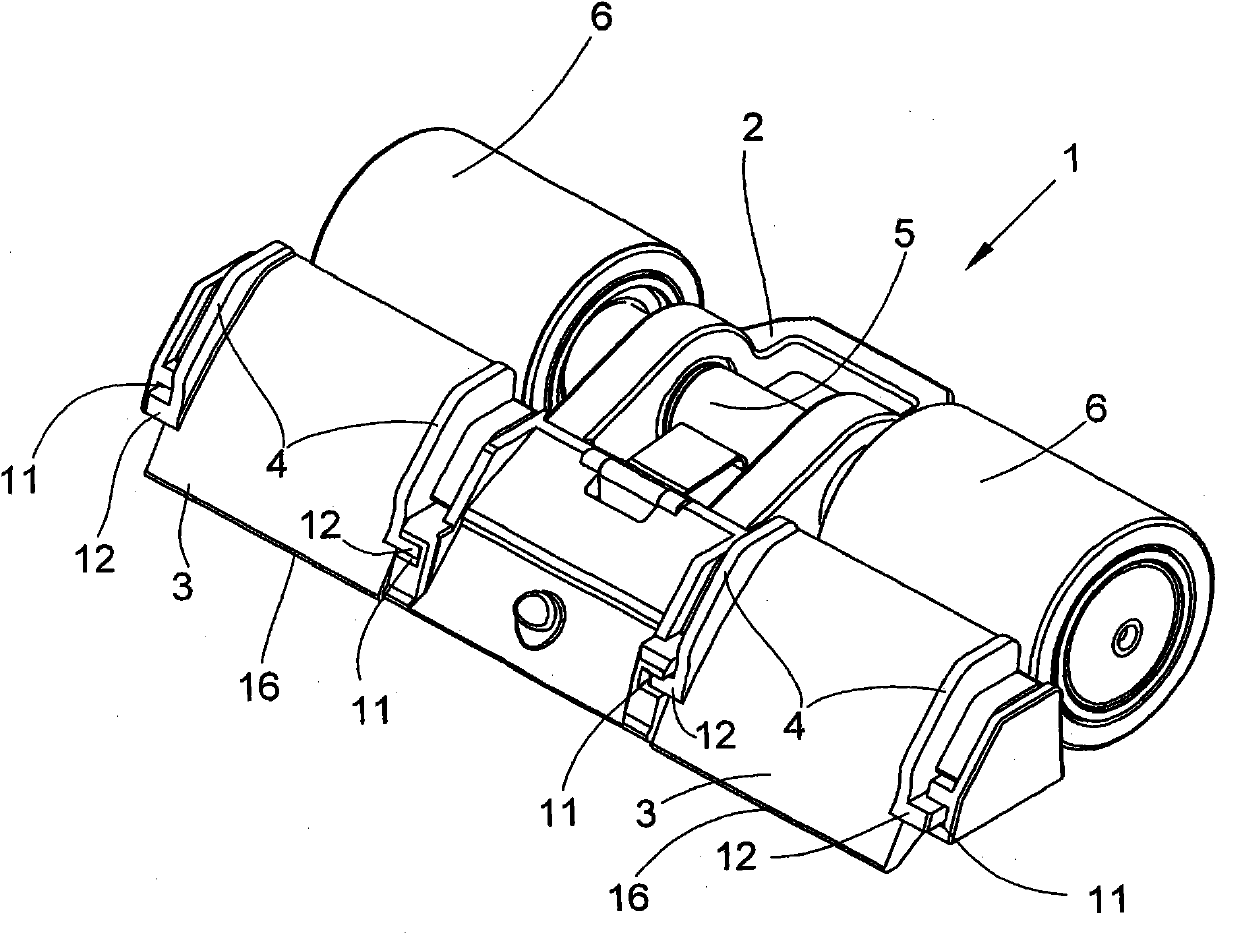

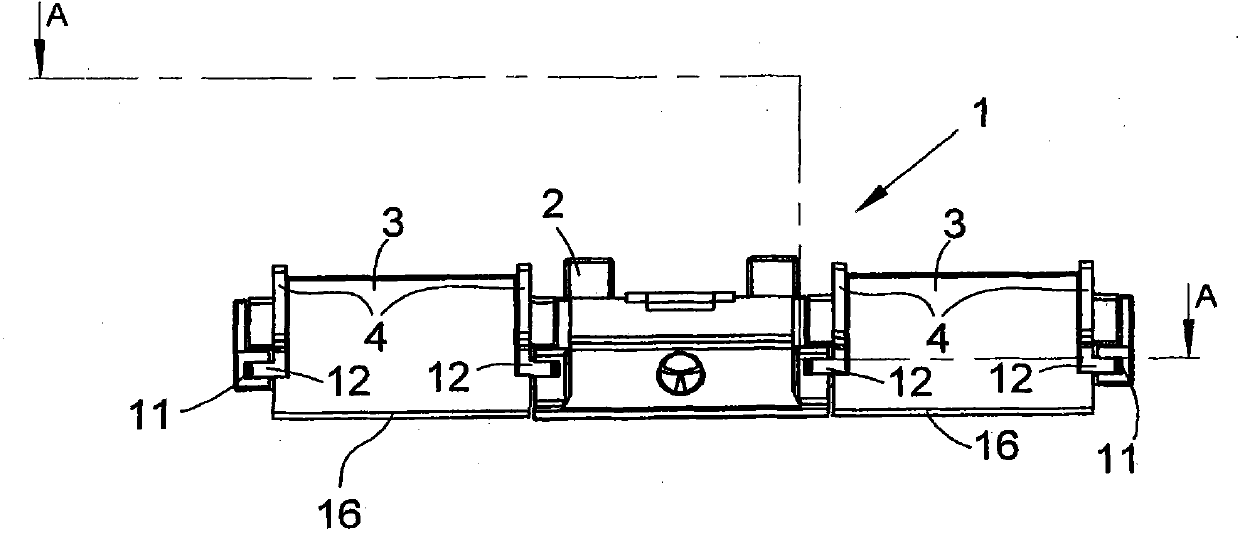

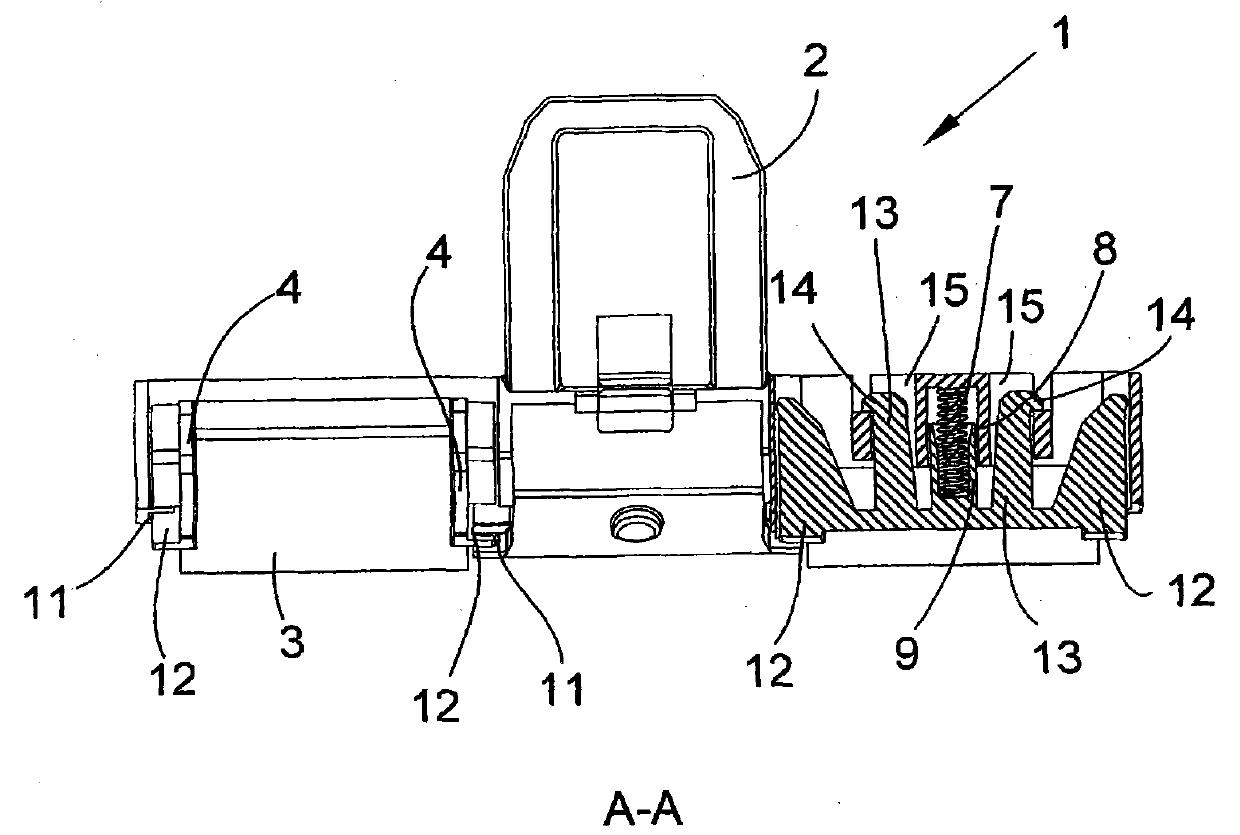

[0026] figure 1 The illustration in FIG. 1 shows an upper apron carrier 1 comprising a middle part 2 and two apron guides 3 . The intermediate piece 2 is mounted on the shaft 5 of the double top roller 6 . The double top rollers 6 are held in a known manner on the guide rods of the top roller carrying and pressing arms. The apron guide 3 is associated with two rotatably mounted top rollers 6 .

[0027] A top apron, not shown, surrounds the top roller 6 and the apron guide 3 . Here, the upper apron is guided by the apron guide 3 and deflected at the deflection edge. The running path width of the apron guide 3 is limited by the partition wall 4 set perpendicular to the direction of movement of the upper apron on the apron guide 3, as from Figure 1 to Figure 3 As can be clearly seen, this prevents the top apron from slipping off the apron guide 3 . In order to tension the upper apron, the apron guides 3 are acted upon with a spring force generated by a spring 7 arranged bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com