Preparation method of chitosan/ acetalized poval medical dressing

A technology of polyvinyl alcohol medicine and polyvinyl alcohol, applied in the field of preparation of polyvinyl alcohol sponge, can solve the problems of low strength, poor resistance to wound adhesion, easy to cause inflammation, etc., and achieve high porosity, good air permeability, and low price Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

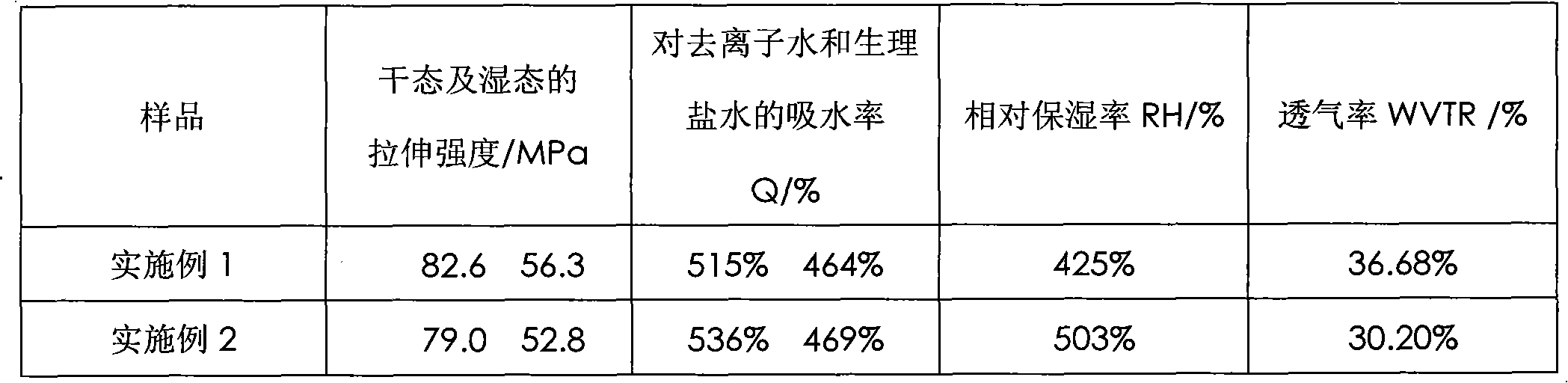

Embodiment 1

[0020] 0.05g chitosan was dissolved in 5% dilute acetic acid aqueous solution to prepare a chitosan solution with a mass fraction of 1.0%. Dissolve 0.05 g of polyvinyl alcohol in 5 ml of boiling water to prepare a 1.0% polyvinyl alcohol solution. The above chitosan solution and polyvinyl alcohol solution are mixed at a volume ratio of 1:1 and then fully stirred to obtain a polyvinyl alcohol / chitosan blend. Weigh 20g of polyvinyl alcohol, dissolve it in 200mL of boiling water, cool down to 50°C, add 0.20g of sodium lauryl sulfate, 22mL of formaldehyde with a mass fraction of 37% and 2.0g of sodium bicarbonate, and stir at 1500r / min for 20min , add 20mL of hydrochloric acid with a mass fraction of 36% at 50°C, continue high-speed stirring to make the solution foam to the maximum volume, keep 50°C, and then drop 10ml of polyvinyl alcohol / chitosan blend into the foam and stir evenly. The foam is injected into a polypropylene mold. Curing at a constant temperature of 50° C. for 1...

Embodiment 2

[0028] Dissolve 0.05g of chitosan in 5% dilute acetic acid aqueous solution to prepare a chitosan solution with a mass fraction of 1.0%. Dissolve 0.05 g of polyvinyl alcohol in 5 ml of boiling water to prepare a 1.0% polyvinyl alcohol solution. The above chitosan solution and polyvinyl alcohol solution are mixed at a volume ratio of 1:1 and then fully stirred to obtain a polyvinyl alcohol / chitosan blend. Weigh 20g of polyvinyl alcohol, dissolve it in 120mL of boiling water, cool down to 35°C, add 0.10g of sodium lauryl sulfate, 20mL of formaldehyde with a mass fraction of 37% and 3.0g of sodium bicarbonate, and stir at 1500r / min for 20min , add 20mL of hydrochloric acid with a mass fraction of 36% at 35°C, continue to stir at 1500r / min to make the solution foam to the maximum volume, keep 35°C, then drop 10ml of polyvinyl alcohol / chitosan blend into the foam and stir Evenly, pour the foam into the polypropylene mold. Curing at a constant temperature of 60° C. for 10 h, takin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com