Continuous on-line analysis device of benzene, total hydrocarbons, methane and CO in carbon dioxide

A carbon dioxide and analysis device technology, applied in the direction of measurement devices, analysis materials, material separation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings.

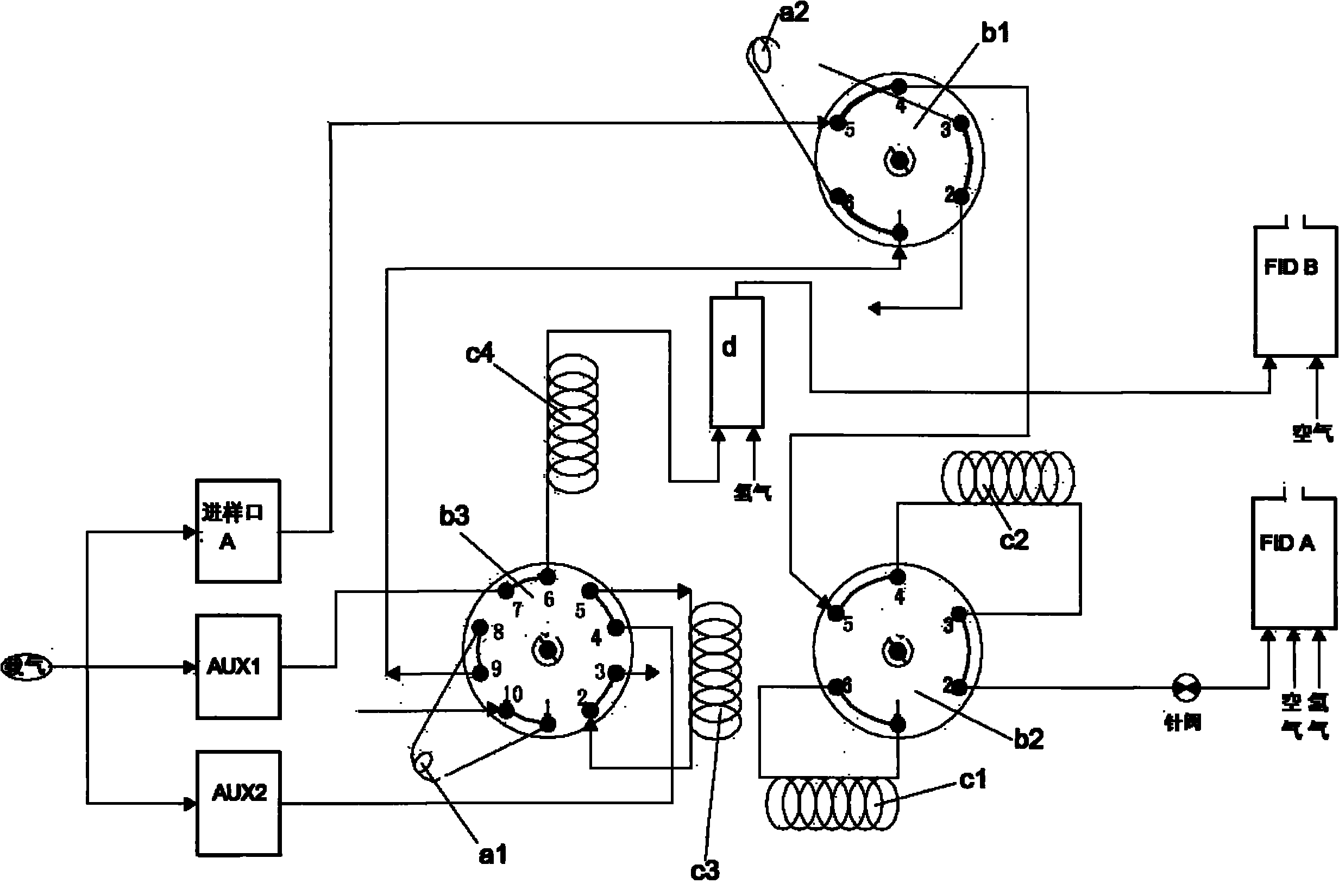

[0031] Such as figure 1 , 2 Shown:

[0032] Continuous online analysis device for benzene, total hydrocarbons, methane and CO in carbon dioxide, including: two carrier gas pipes (a1, a2), the first six-way flat valve b1, the second six-way flat valve b2, the ten-way flat valve b3, the second One to the fourth chromatographic column (c1, c2, c3, c4), methanation conversion tube d, gas chromatograph;

[0033] The gas chromatograph is equipped with a first hydrogen flame detector (FIDA) and a second hydrogen flame detector (FIDB);

[0034] The six ports of the first six-way planar valve and the second six-way planar valve are numbered counterclockwise on the valve disc surface: port one to port six (marked 1 to 6 on the valve disc); The ten ports of the valve are numbered counterclockwise on the valve disc surface in sequence: port one to port ten (valve disc marks ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com