Film dressing with an improved grip tab

A technology of plastic film and back layer, applied in dressings, adhesive dressings, layered products, etc., can solve problems such as film damage, film wrinkling, and no longer adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] specific implementation plan

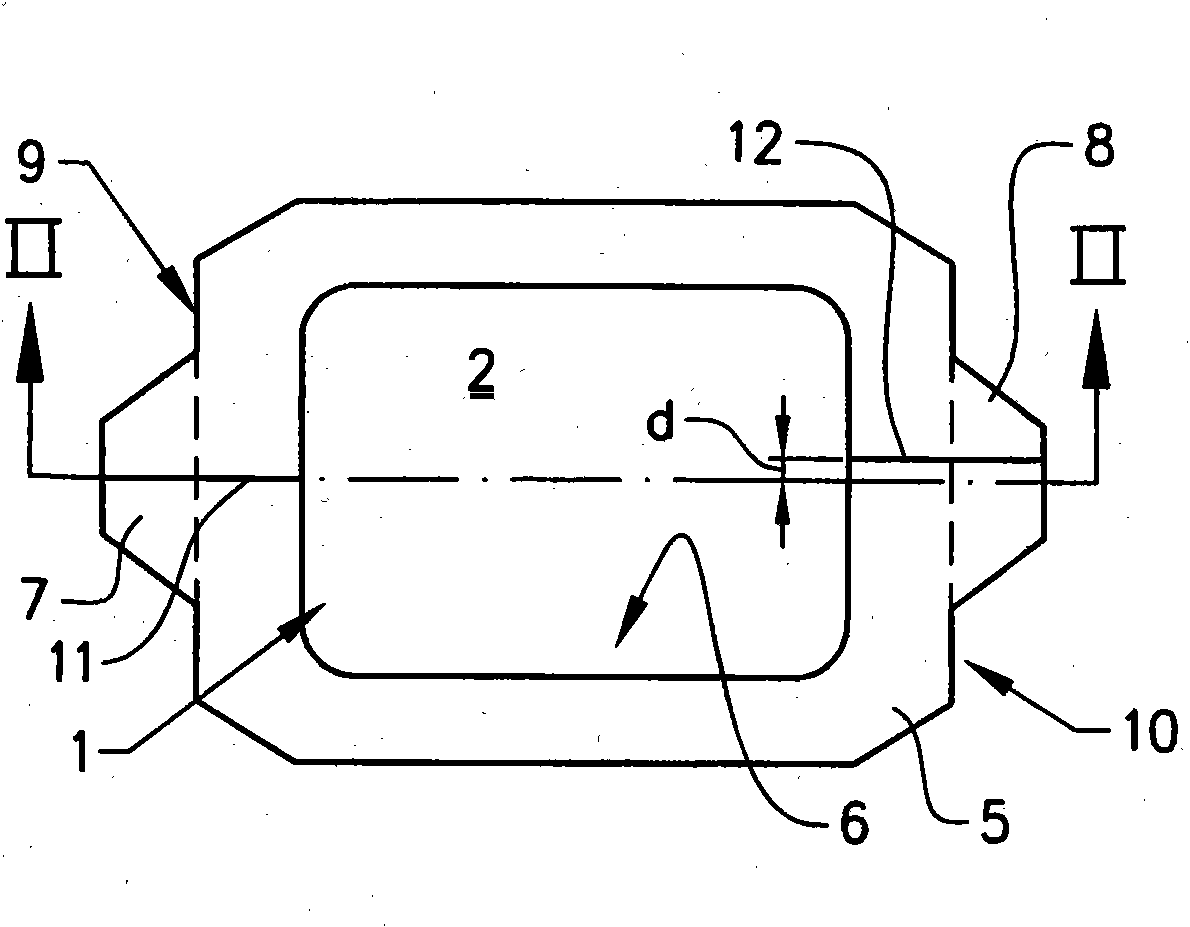

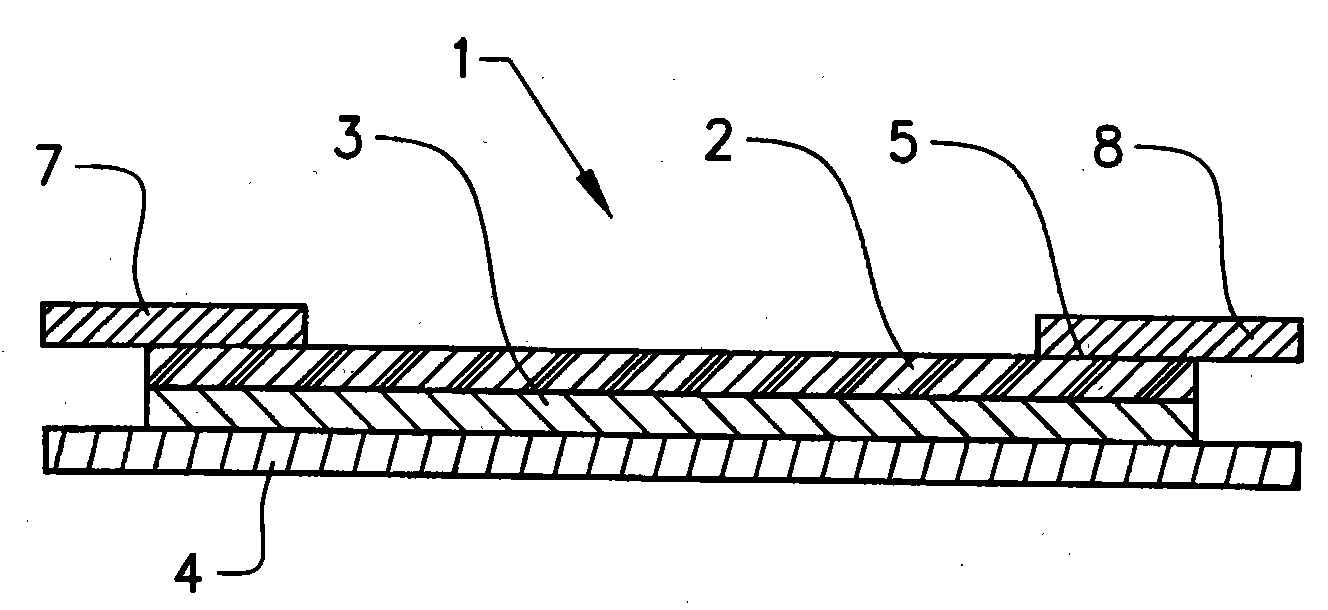

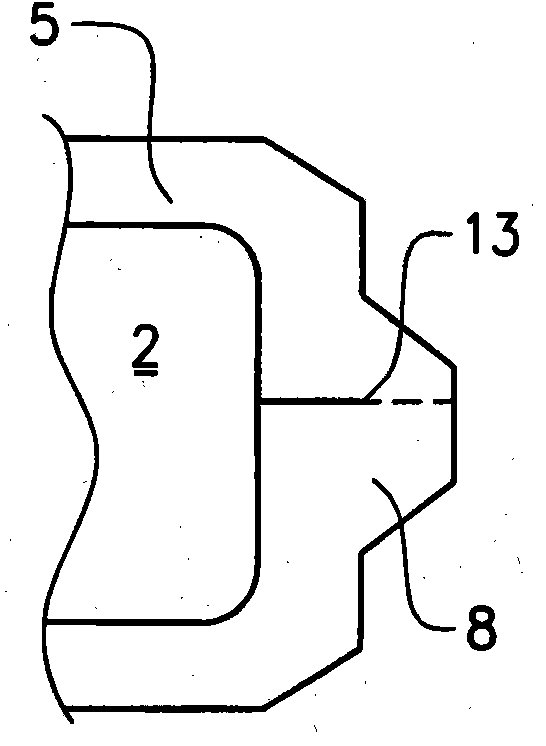

[0023] figure 1 and 2 A film dressing 1 according to a first preferred embodiment of the invention is shown. The dressing 1 generally comprises a plastic film 2 coated on the underside with an adhesive layer 3 , a protective layer 4 on the underside of the adhesive coating 3 and a backing layer 5 on the upper side of the plastic film 2 .

[0024] The terms "upper side" and "lower side" and similar expressions in the specification refer to the figure 1 Interrelationships between dressing components in dressing positions shown.

[0025] The protective layer 4 is detachably attached to the adhesive coating 3 . The function of the protective layer 4 is to protect the adhesive coating before application so that particles or other impurities do not adhere to the adhesive coating 3 and impair adhesion. The protective layer 4 also prevents accidental sticking of the dressing in the wrong place when the dressing is handled prior to intended ap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com