Automatic burning temperature control system

A temperature control system and automatic technology, applied in the control of combustion, lighting and heating equipment, etc., can solve problems such as over-temperature, low temperature, regional temperature channeling, and inability to achieve process effects, achieve no temperature fluctuations, and increase equipment utilization. , the effect of less heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

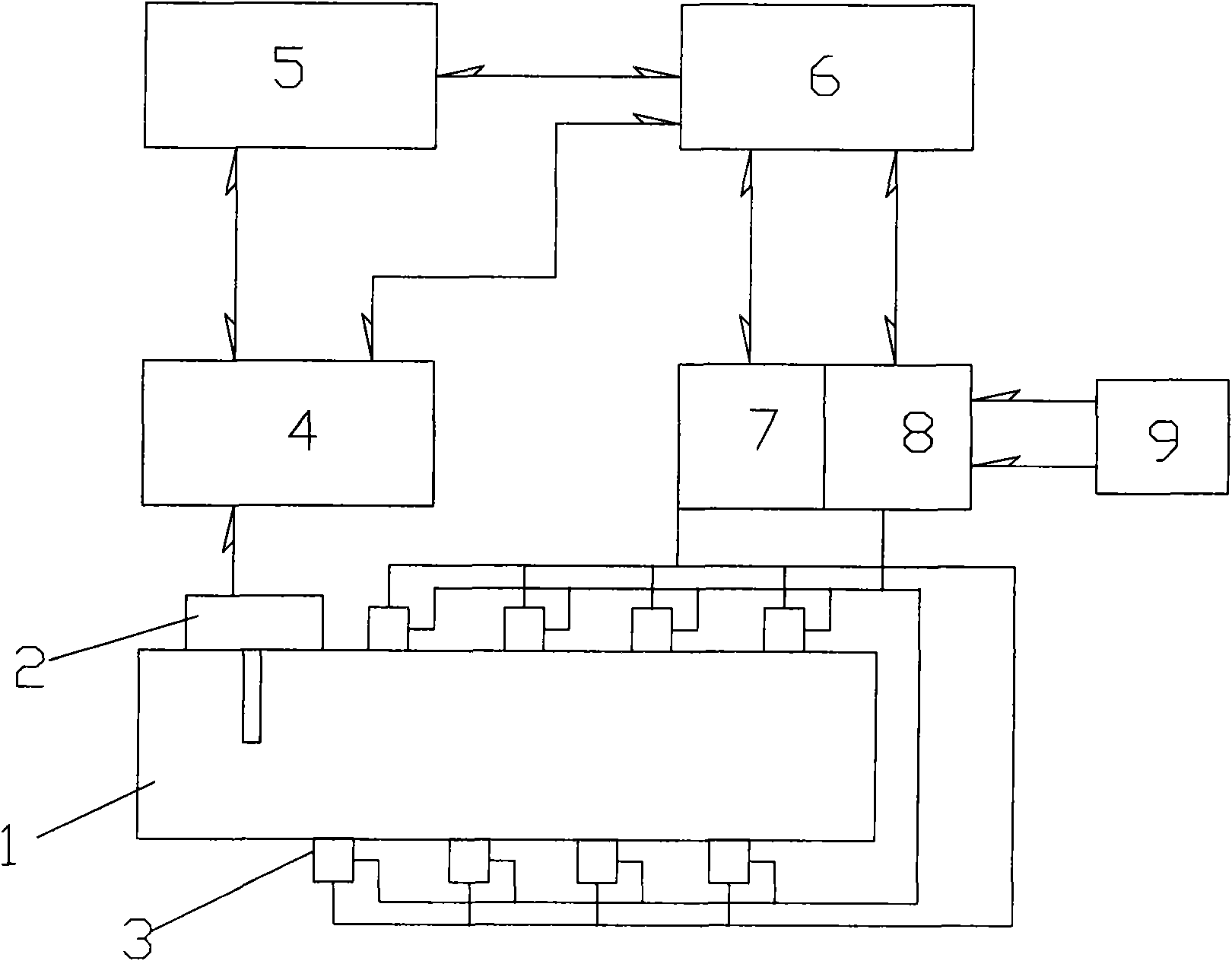

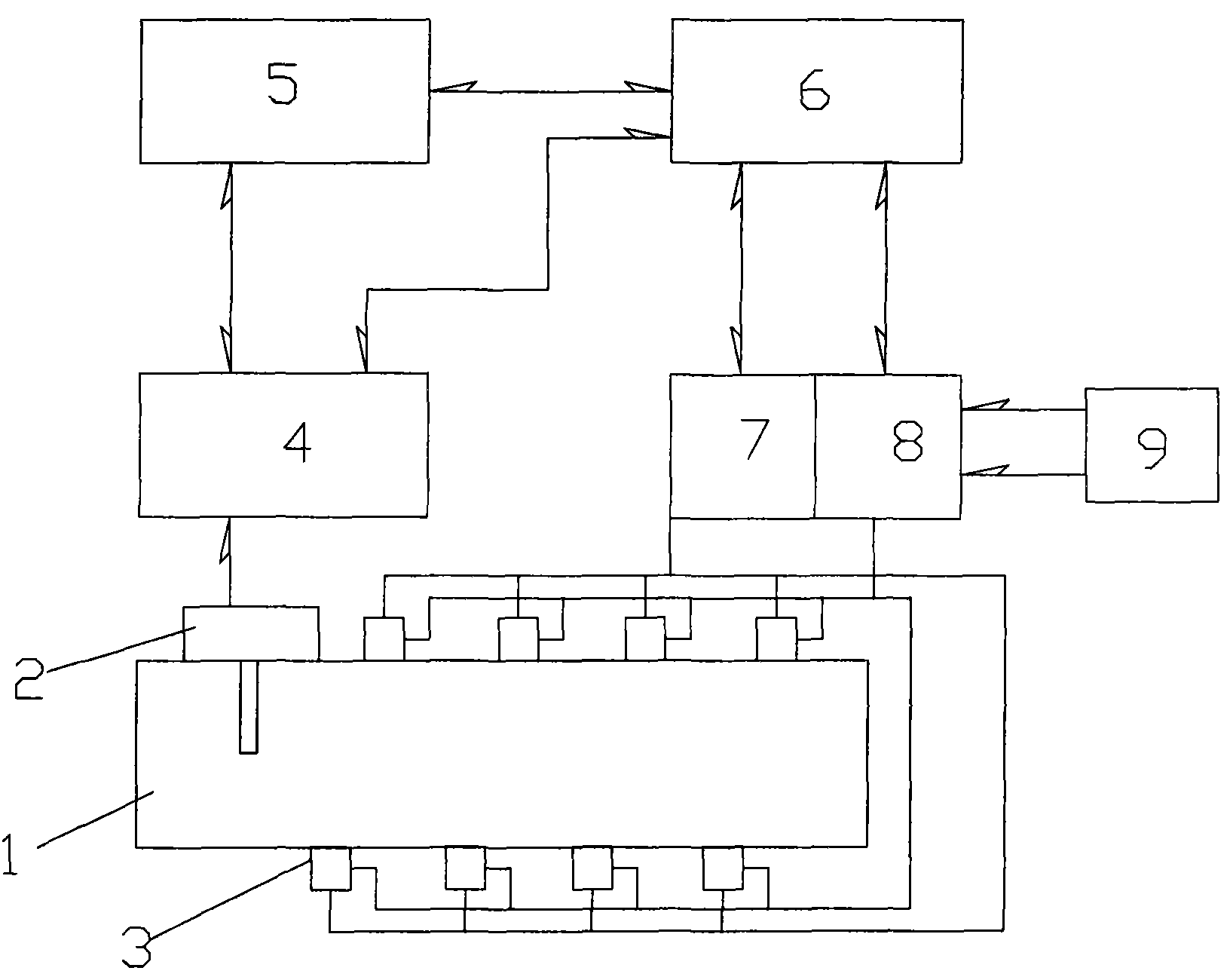

[0009] A kind of burning automatic temperature control system as shown in the accompanying drawing, it comprises furnace 1, described furnace 1 is provided with thermocouple 2 and burner 3 described thermocouple 2 is connected with temperature instrument 4, and described temperature instrument 4 is connected with respectively The upper computer 5 is connected with the programmable controller 6, and the programmable controller 6 is connected with the upper computer 5, the proportional valve 7 and the electromagnetic valve 8 respectively, and the proportional valve 7, the electromagnetic valve 8 are connected with the burner 3, and the Solenoid valve 8 links to each other with air gas tank 9.

[0010] The principle is: the combustion temperature control is collected by the thermocouple 2 and the temperature signal inside the furnace 1 is transmitted to the temperature instrument 4, and the temperature instrument 4 then transmits the control signal (PID) to the programmable contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com