Device for driving a generator by a belt drive of an internal combustion engine

A technology of belt drive and internal combustion engine, applied in the direction of machine/engine, hoisting device, element with teeth, etc., can solve the problem of low torsional rigidity and achieve the effect of simple assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

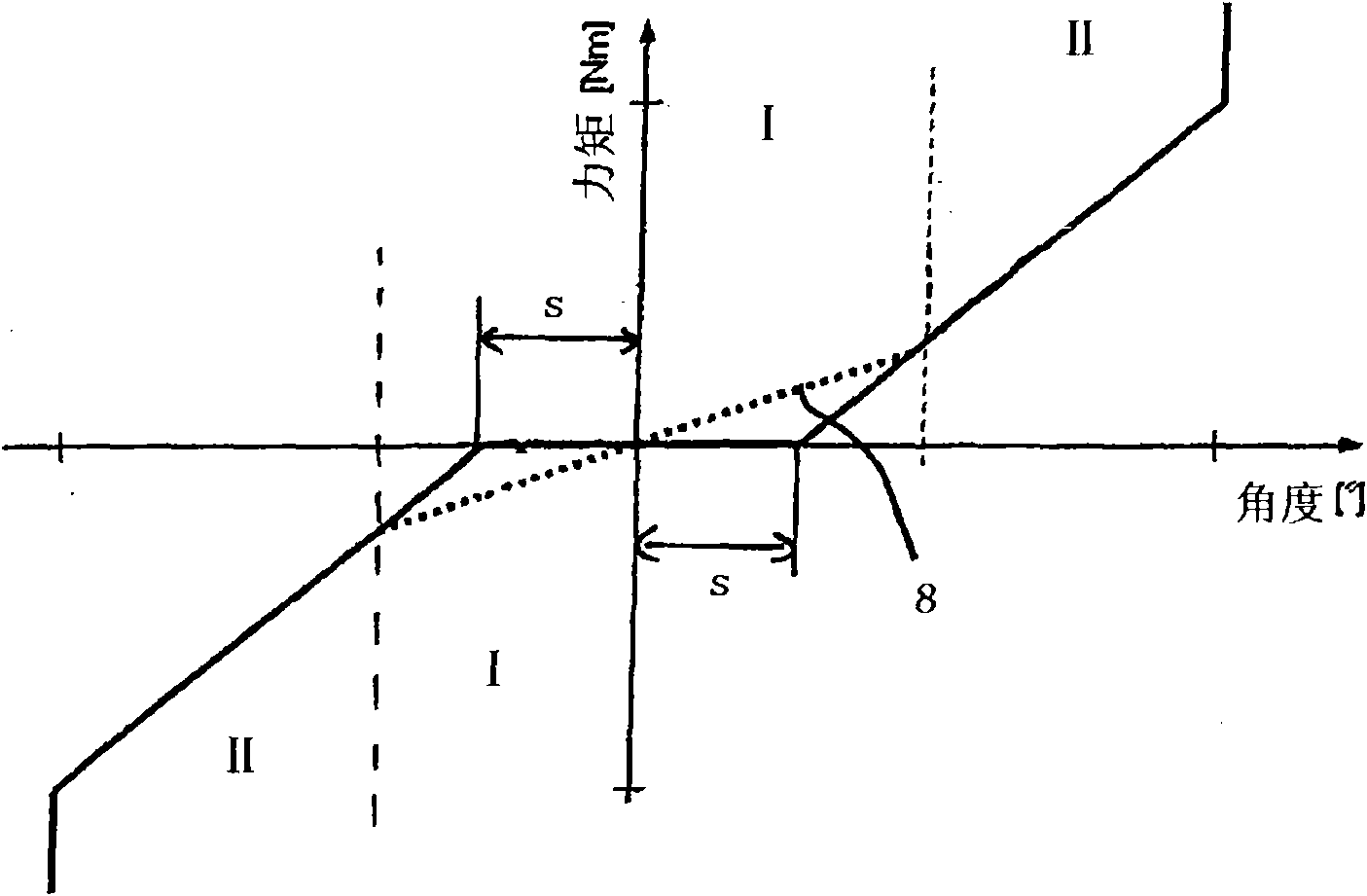

[0019] exist figure 1 shows a schematic sectional view of a device according to the invention for connecting a generator to a belt drive of an internal combustion engine. In this arrangement, a belt pulley 1 is guided in a rotatable manner relative to a hub 2 , which is mounted on a shaft 3 of a generator. In this case, pulley 1 is constructed in a manner known to those skilled in the art and is connected to the crankshaft of the internal combustion engine via a belt (not shown here). When the internal combustion engine is running, the pulley 1 is twisted via the belt drive, and the pulley 1 transmits this rotational movement indirectly to the hub 2 , thereby driving the generator via the shaft 3 . In order to achieve the transfer of rotational motion from the pulley 1 to the hub 2 while avoiding the introduction of rotational inhomogeneities into the generator drive, between the pulley 1 and the hub 2 and between the pulley 1 and the hub 2 and defined radially apart Arcuate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com