Concrete pre-stress hollow square pile and molding method thereof

The technology of a hollow square pile and a forming method, which is applied in the construction field, can solve the problems such as hidden hidden dangers, high pile damage rate, and impact on the compressive and impact resistance performance of the pile body.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to have a clearer understanding of the technical features, objectives and effects of the present invention, specific embodiments of the present invention will now be described with reference to the accompanying drawings. Among them, the same parts are given the same reference numerals.

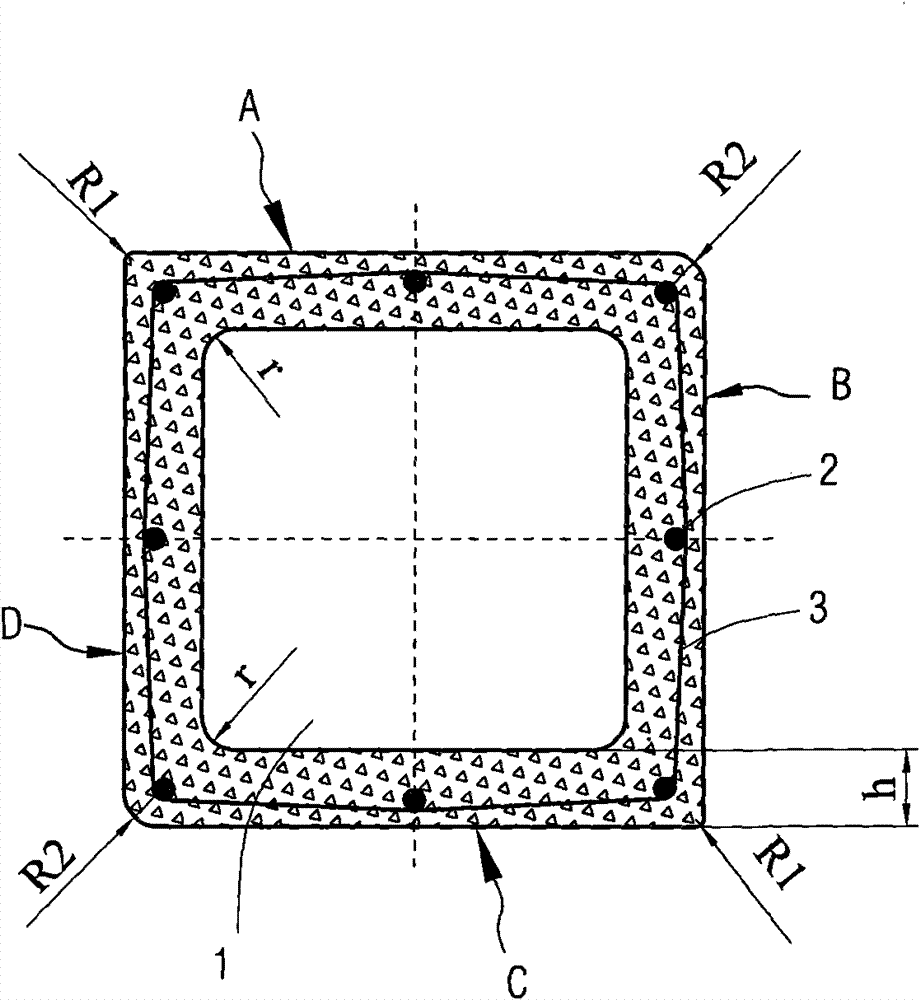

[0028] figure 1 Shown is a cross-sectional view of a concrete prestressed hollow square pile according to a specific embodiment of the present invention. As shown in the figure, along the longitudinal axis of the concrete prestressed hollow square pile, there is a cross-sectional view of the concrete prestressed hollow square pile at its center. The center through hole 1 of the stress hollow square pile, the outer cross section of the concrete prestressed hollow square pile is square, and the cross section of the center through hole 1 of the concrete prestressed hollow square pile is also square; and the cross section of the concrete prestressed hollow square pile The wall thickn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com