Carpet loom bobbin creel

A creel and loom technology, applied in looms, textiles, textiles and papermaking, etc., can solve the problems of unsolvable yarn, unweaving, and large shelf space, and achieve the effect of novel structural design and low friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

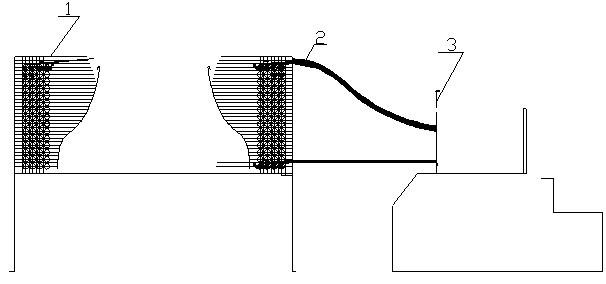

[0010] Embodiment 1: with reference to attached Figure 1-3 . Carpet loom creel, it comprises carpet loom creel 1, and carpet loom creel 1 is prior art, does not describe here. In the creel 1 of the carpet loom, yarn is hung on both sides of each group of creels (each yarn is equipped with a bobbin), and the hung yarn passes through the yarn guide tube 2 to the yarn guide plate 3 respectively, and the yarn guide plate 3 Be prior art, do not describe here. figure 2 Each line in represents a yarn guiding tube 2. The laying path of the yarn guide tube adopts a flat laying design.

[0011] The yarn guide tube 2 is located between the bobbins with yarn hanging on both sides. This is because there is a space between the bobbins with yarn hanging on both sides. The present application just utilizes this space to arrange the yarn guide tube 2 .

[0012] The yarn guide tube 2 is a combination of multiple straight tubes and arc tubes. The purpose of the arc tube is to guide the yar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com