Fixing seat of elevator guide rail

A technology for elevator guide rails and fixed seats, which is used in elevators, transportation and packaging, etc., can solve problems such as inability to guarantee parallelism, force deflection of guide rails, loud noise, etc., so as to save the complicated process of gaskets and ensure smooth operation of bridge boxes. , to ensure the effect of installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

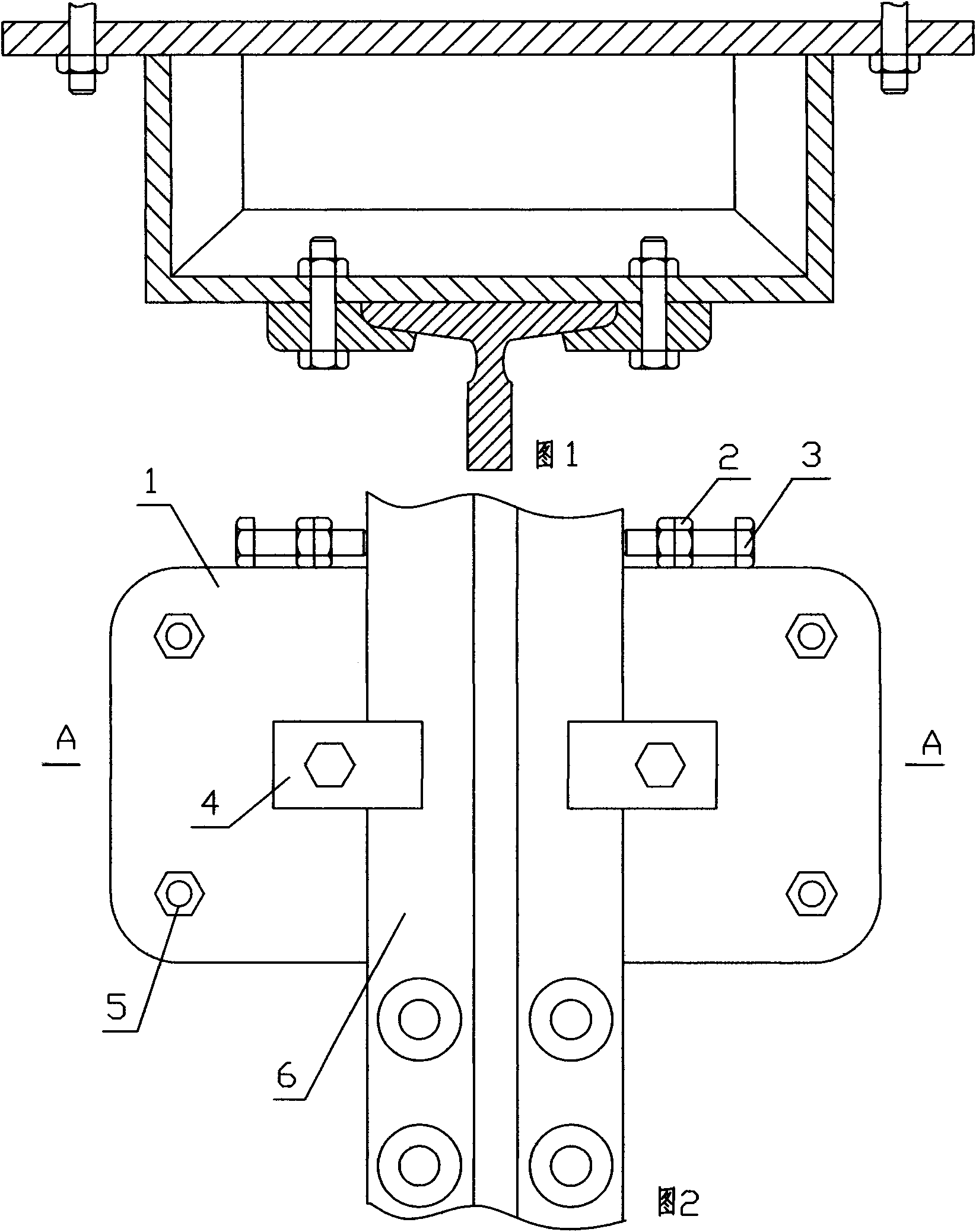

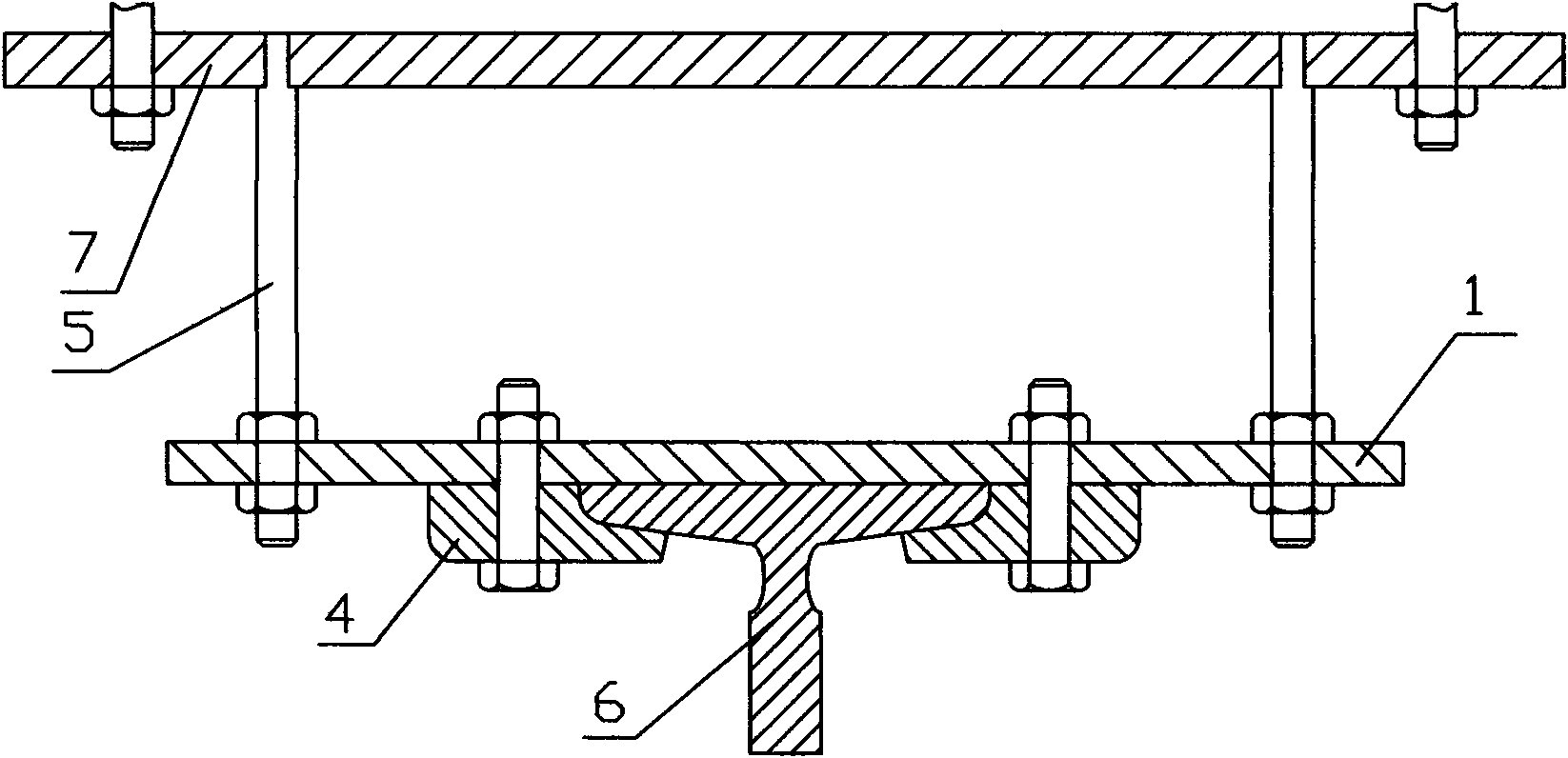

[0011] The structure of the present invention consists of a bottom plate 7, a "door"-shaped bracket, and a pressure plate 4, and is characterized in that: the "door"-shaped bracket is composed of four pins 5 vertically welded to the four corners of the bottom plate 7, a rectangular outer plate 1, and eight nuts , each pin column 5 outer parts are machined with external threads, and the outer plate 1 is evenly distributed with through holes corresponding to the four pin columns 5, after the four pin columns 5 respectively pass through the four through holes of the outer plate 1, each Two nuts are used to fix the outer plate 1 on both sides of the outer plate 1 on the external thread of the outer part of the root pin 5, and the middle part of the outer plate 1 is provided with two fixing holes for the pressure plate 4, and two fixing bolts and nuts are used to fix the two pressure plates. 4 are respectively fixed on the outer plate 1.

[0012] The four corners of the bottom are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com