Pressure-sensitive adhesive composition, protective film, polarizer and liquid crystal display comprising the same

A technology of pressure-sensitive adhesives and compositions, applied in the direction of adhesive types, ester copolymer adhesives, adhesives, etc., can solve the problems of reducing low-speed peel strength, achieve excellent antistatic performance, and prevent static electricity , good processability and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

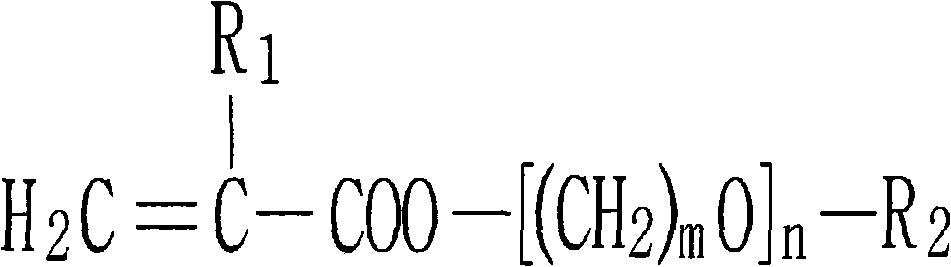

Method used

Image

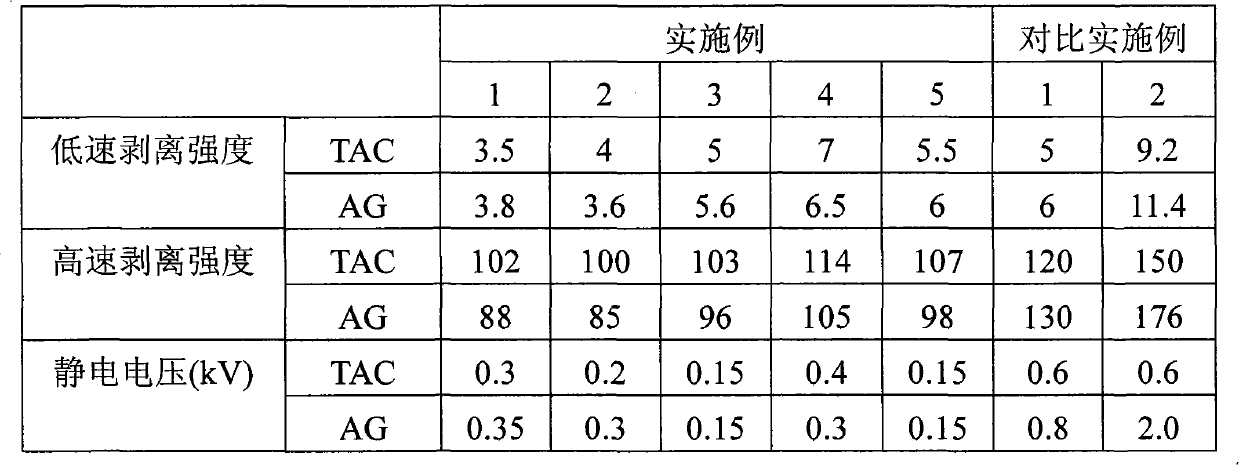

Examples

Embodiment

[0092] Although the embodiment of the present invention has been described in detail, it is obvious to those skilled in the art that various changes and improvements can be made within the scope of the technical idea of the present invention, and these changes and improvements are included in the appended claims .

[0093] Preferred embodiments of the present invention will be provided in the following examples to help the understanding of the present invention, but these embodiments are only for the purpose of illustration, not limiting the scope of the present invention.

preparation Embodiment 1

[0095] In the 1L reactor that is equipped with cooling system, add by the 2-ethylhexyl acrylate (EHA) of 90 parts by weight, the lauryl acrylate of 5 parts by weight, the methoxy triethylene glycol acrylate of 2 parts by weight and A monomer mixture composed of 3 parts by weight of 2-hydroxyethyl acrylate (HEA). Then, 100 parts by weight of ethyl acetate (EAc) was added thereto as a solvent. To remove oxygen, purge with nitrogen for 60 minutes. Then, the temperature was kept at 70° C., 0.1 parts by weight of azobis(2-methylbutyronitrile) (Wako, V-59) was added thereto as an initiator, followed by reaction for 6 hours. After the reaction, the resulting product was diluted with ethyl acetate (EAc) to prepare an acrylic copolymer having a solid content of 44% by weight, a weight average molecular weight of 580,000, and a molecular weight distribution of 7.0.

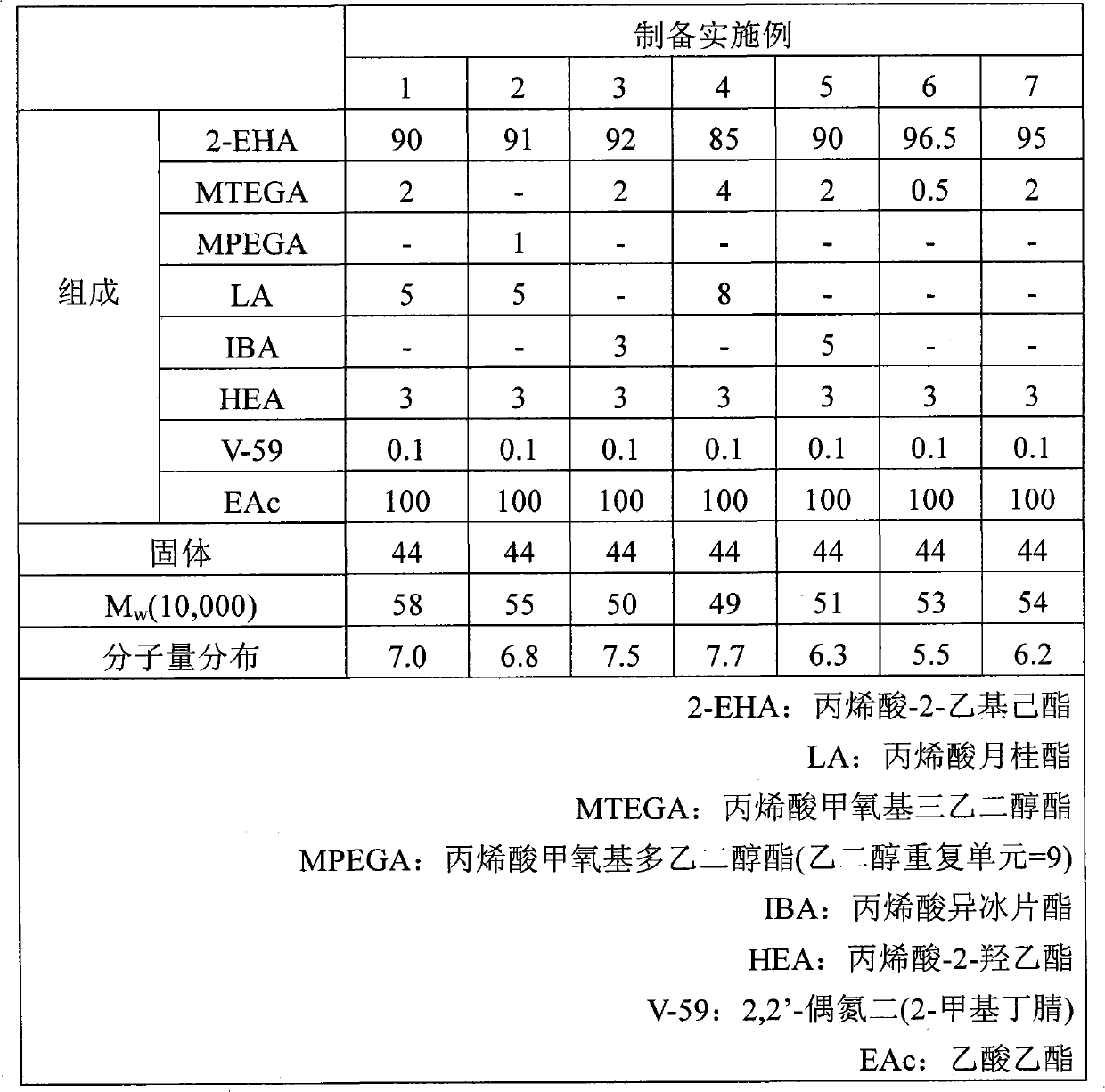

preparation Embodiment 2-7

[0097] An acrylic copolymer was prepared in the same manner as described in Preparation Example 1 except using the components and composition shown in Table 1.

[0098] Table 1

[0099]

PUM

| Property | Measurement | Unit |

|---|---|---|

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com