Device for measuring mass of movable fiber band

A technology of measuring device and sliver, which is applied in the direction of measuring device, electromagnetic measuring device, electromagnetic/magnetic thickness measurement, etc., can solve the problems of fiber contamination, jeopardizing the function of the device, etc., and achieve the effect of good temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

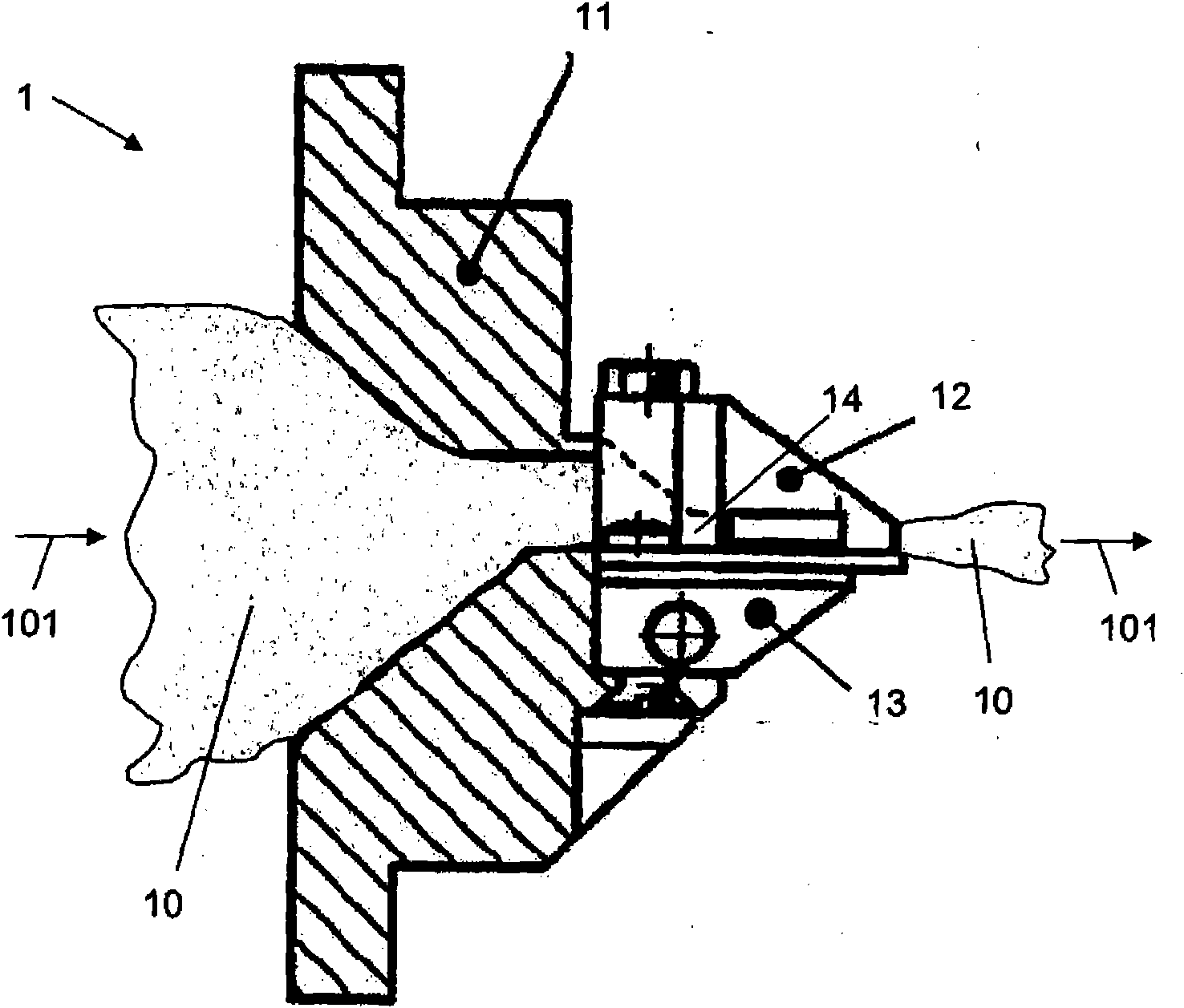

[0038] figure 1 An embodiment of a device 1 according to the invention is shown for measuring the quality of a tampon 10 . The device 1 comprises a sliver horn or horn head 11 , a sliver compacting part 12 and a sensor part 13 . The sliver 10 is moved along its longitudinal axis indicated by arrow 101 . After entering the device 1 , the sliver 10 is compacted in the sliver horn 11 and passes through a narrow measuring channel 14 between the sliver compacting part 12 and the sensor part 13 . The sensor part 13 comprises measuring means for measuring the pressure exerted by the tampon 10 in the measuring channel 14 . Depend on figure 1 The shown elements of the device 1 substantially correspond to those of US-4,864,853A. The subsequent figures depict the sensor part 13 in detail, and this sensor part 13 differs substantially from the prior art.

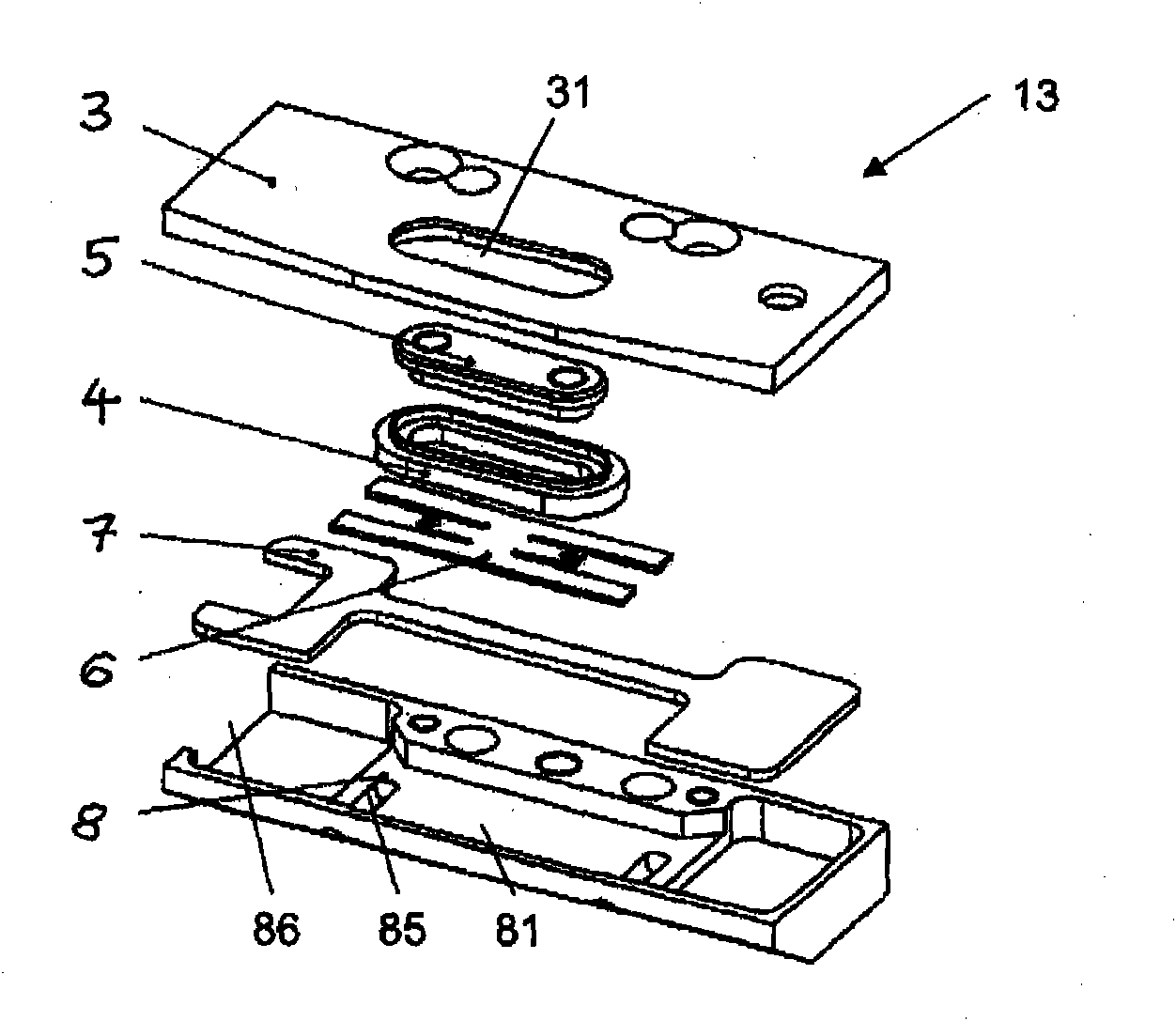

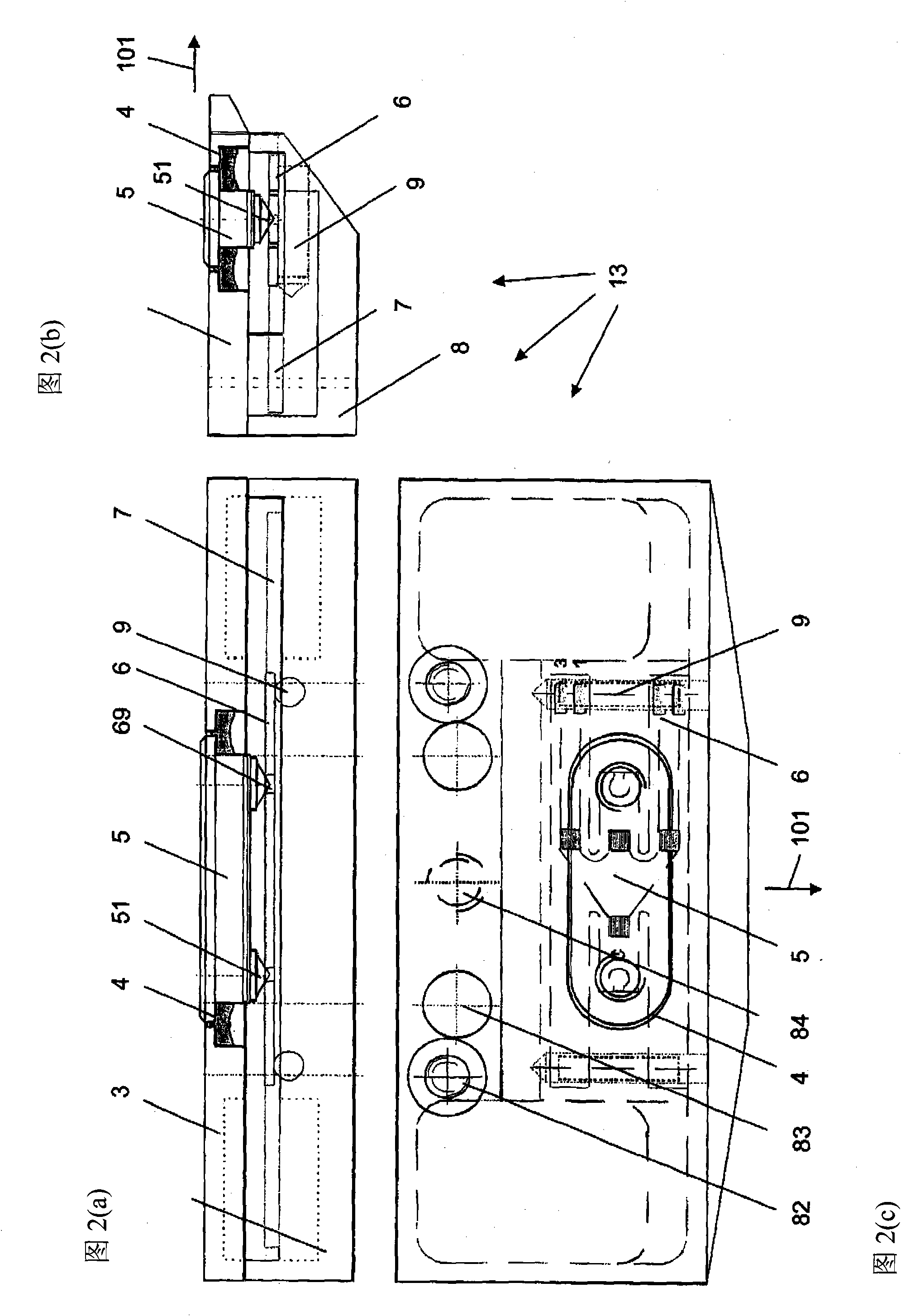

[0039] FIG. 2 shows three different views of the sensor component 13 , in which some elements are drawn at least partially in a tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com