Electrostatic type crosrol web cleaner for carding machine

A technology of carding machine and cleaner, which is applied in the field of carding machine textile, textile machinery, and carding machine, can solve the problems that electrostatic cotton web cleaners are rare, and is beneficial to the widespread application and production. The effect of improving strip quality and changing shape slightly

Inactive Publication Date: 2010-12-08

EASTERN LIAONING UNIV

View PDF4 Cites 24 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Previous studies on cotton web cleaners mainly focused on the use effect of cotton web cleaners, the influence of different forms of cotton web cleaners, air volume, suction form and related process parameters on the quality of raw sliver, etc. There are not many research literatures on electrostatic cotton net cleaner

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment approach 1

specific Embodiment approach 2

specific Embodiment approach 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

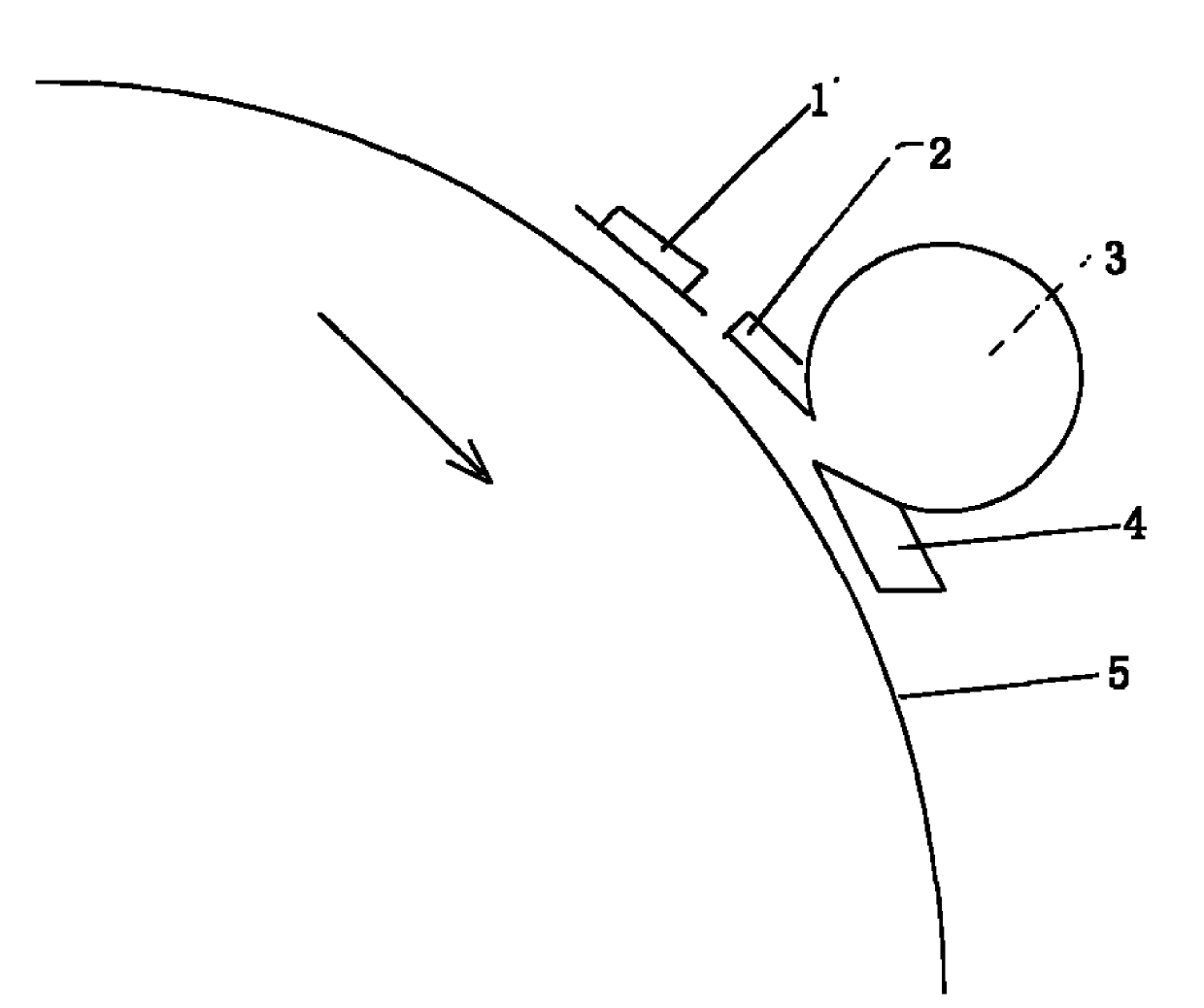

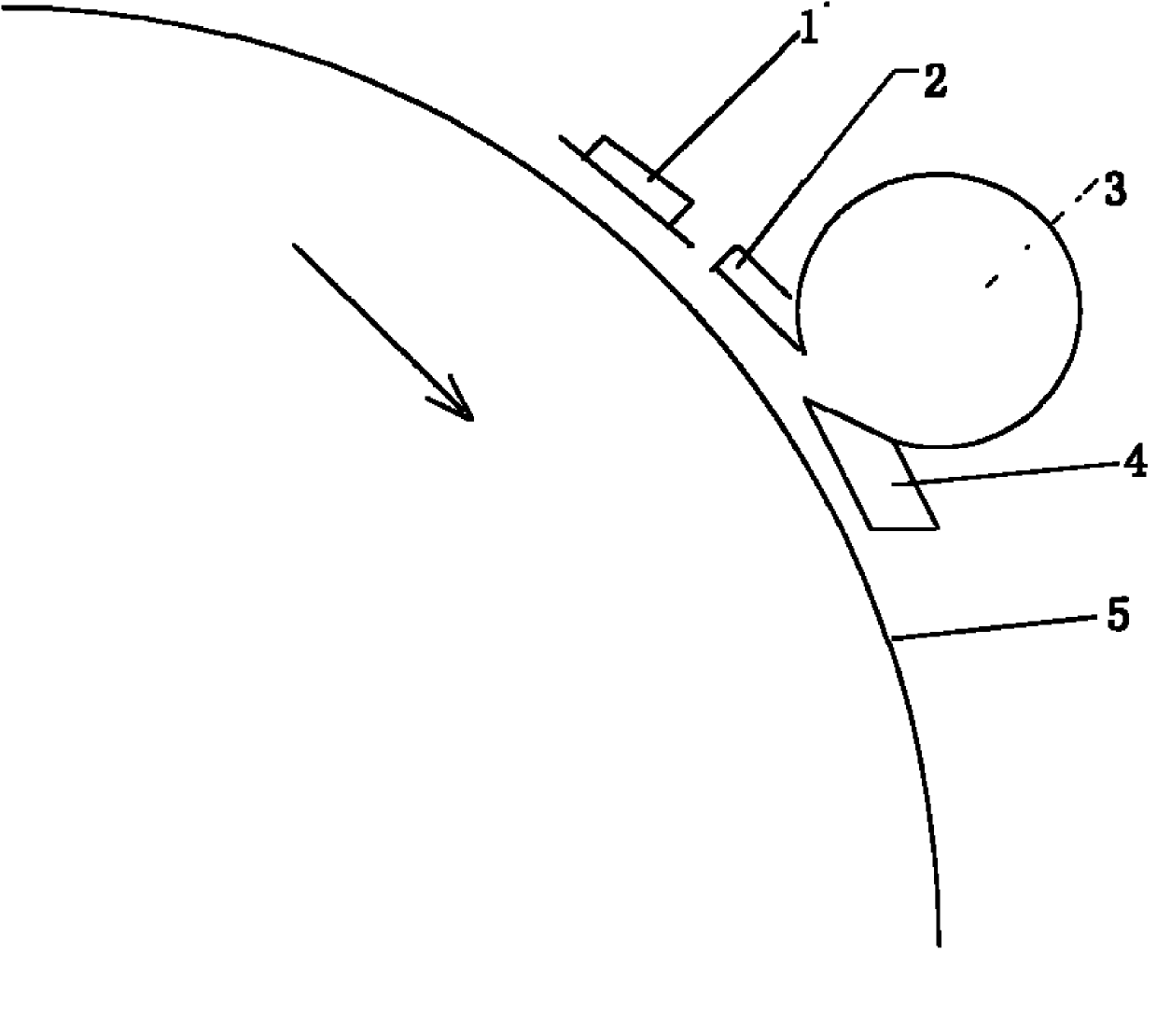

The invention provides an electrostatic type crosol web cleaner for a carding machine, relating to the technical filed of textile, taking gauge adjustment of electrostatic plates and voltage adjustment as the key technology, and providing the installation form and the use effect of the electrostatic type crosol web cleaner for the carding machine. In the invention, a guide plate type crosrol web cleaner with the electrostatic plate is loaded at the position of a front knife plate of the carding machine; under the normal production condition, the different gauges between the electrostatic plate and cylinder as well as the different voltages are adjusted to influence the quality of a carded sliver; a Uster AFIS filament tester is used for carrying out quality testing on the carded sliver produced under the condition of the different gauges of the static electric plates and the voltages, a statistical analysis technique is used for analyzing the testing result which shows that under the condition of the appropriate dereferencing of the voltages and the gauges of the static electric plates, when the electrostatic type crosol web cleaner for the carding machine is loaded to the position of the front knife plate of the carding machine, the quality of the carded sliver can be improved. In the process of utilization, the loaded electrostatic plates have simple structure and small change on the traditional crosol web cleaner form, are convenient to manufacture and install and are favor of wide application and dissemination.

Description

technical field The patented electrostatic cotton web cleaner for carding machines of the present invention relates to the field of textile machinery; in particular, it relates to the textile technical field of carding machines; in particular, it relates to the textile technical field of carding machines equipped with electrostatic cotton web cleaners. Background technique In 1983, at the ITMA83 held in Milan, Italy, Germany's Tejuzler Company installed a front cotton web cleaner on the DK715 carding machine for the first time. Because the cotton web cleaner does play a very important role in removing impurities and lint, the use of cotton web cleaner has become the development trend of high-production carding machines and old machine renovations all over the world since then, and the cotton web There is also a gradual increase in cleaners. Previous studies on cotton web cleaners mainly focused on the use effect of cotton web cleaners, the influence of different forms of c...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): D01G15/76

Inventor 孙鹏子曹继鹏韩贤国

Owner EASTERN LIAONING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com