Jointing die for plastic hose extruder

A technology for plastic hoses and extruders, which is used in household appliances, other household appliances, applications, etc., can solve the problems of limited mold structure and function, inability to join raw materials, etc., and achieve the effect of reducing printing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

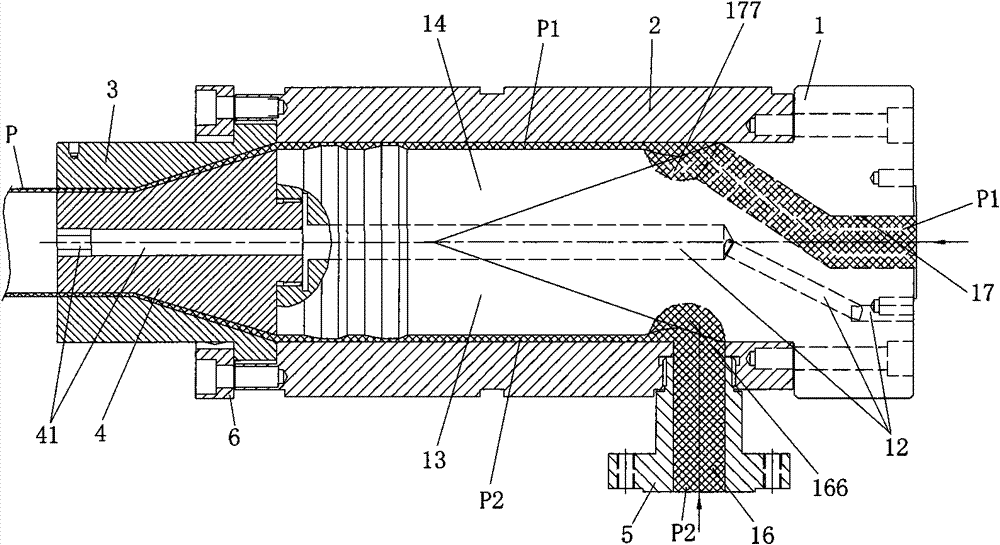

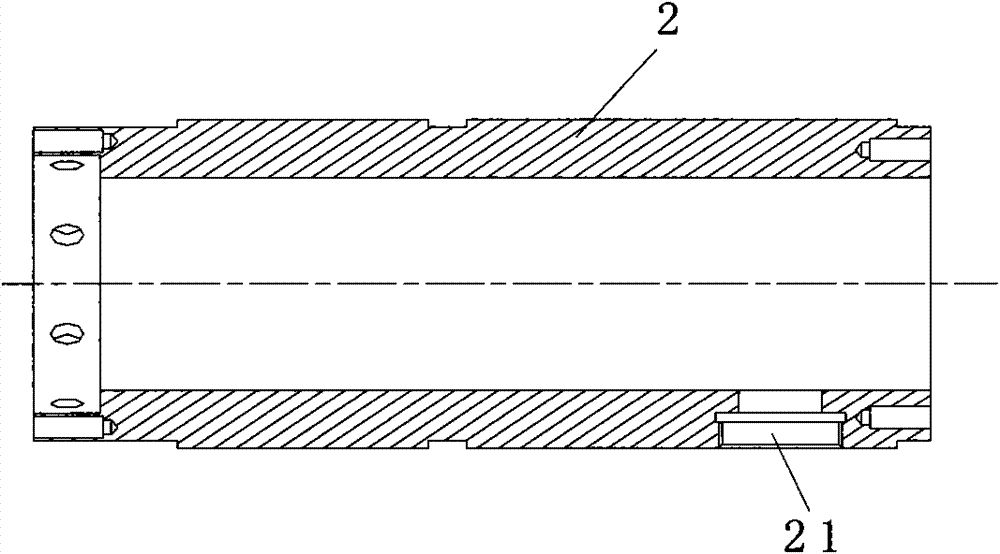

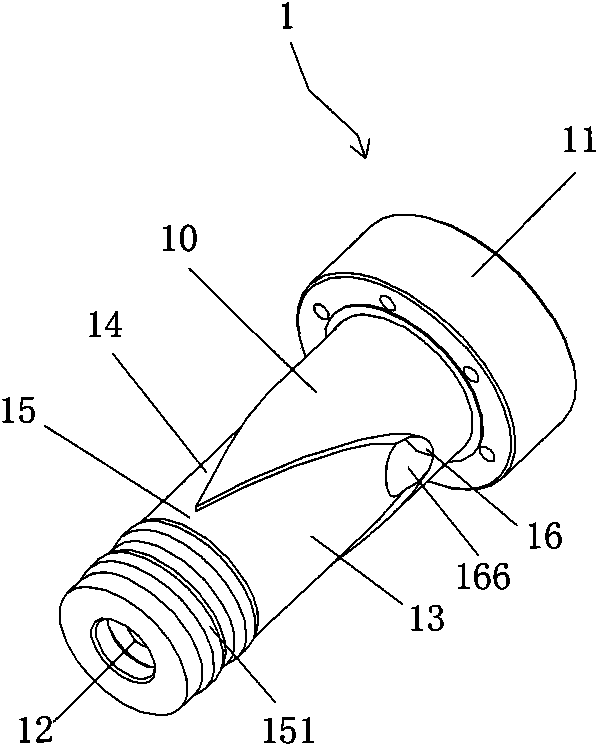

[0020] see Figure 1~4 , The present invention is provided with guide material core 1, guide material mold sleeve 2, discharge die lip 3 and discharge die core 4. The material guide core 1 is a T-shaped material guide core, and the rear end boss 11 of the material guide core 1 is connected with the rear end of the material guide mold cover 2 through fasteners. The guide mold core 1 is provided with an exhaust hole 12, and the outer surface 10 of the guide mold core 1 is provided with a diversion groove. The V-shaped steps on both sides of the outer surface 10 of the material guide core 1 are isolated, the areas of the two distribution grooves 13 and 14 are the same (or different), and the phase difference between the two distribution grooves 13 and 14 is 180°. The front part of the diversion groove is an annular confluence groove 15, and the confluence groove 15 is provided with a corrugated tubular groove 151. The corrugated tubular groove 151 can increase pressure, uniform ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com