Planer multiple degree of freedom controllable loading mechanism

A technology of loading mechanism and degree of freedom, applied in the direction of mechanically driven excavators/dredgers, etc., can solve problems such as high requirements for hydraulic system components, complex hydraulic systems, overheating, etc., achieve low manufacturing and processing requirements, and solve high parts requirements , the effect of reducing the weight of the arm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

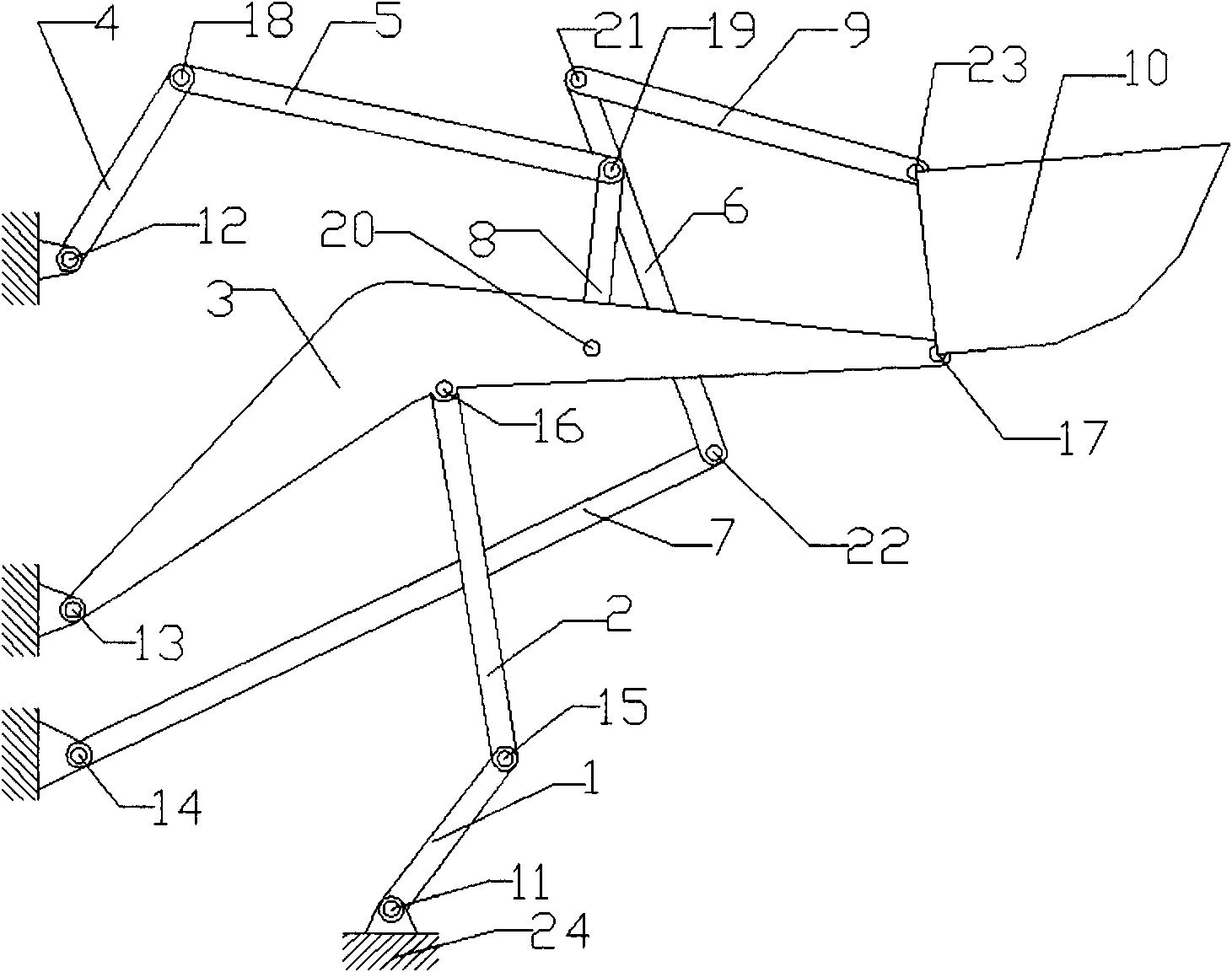

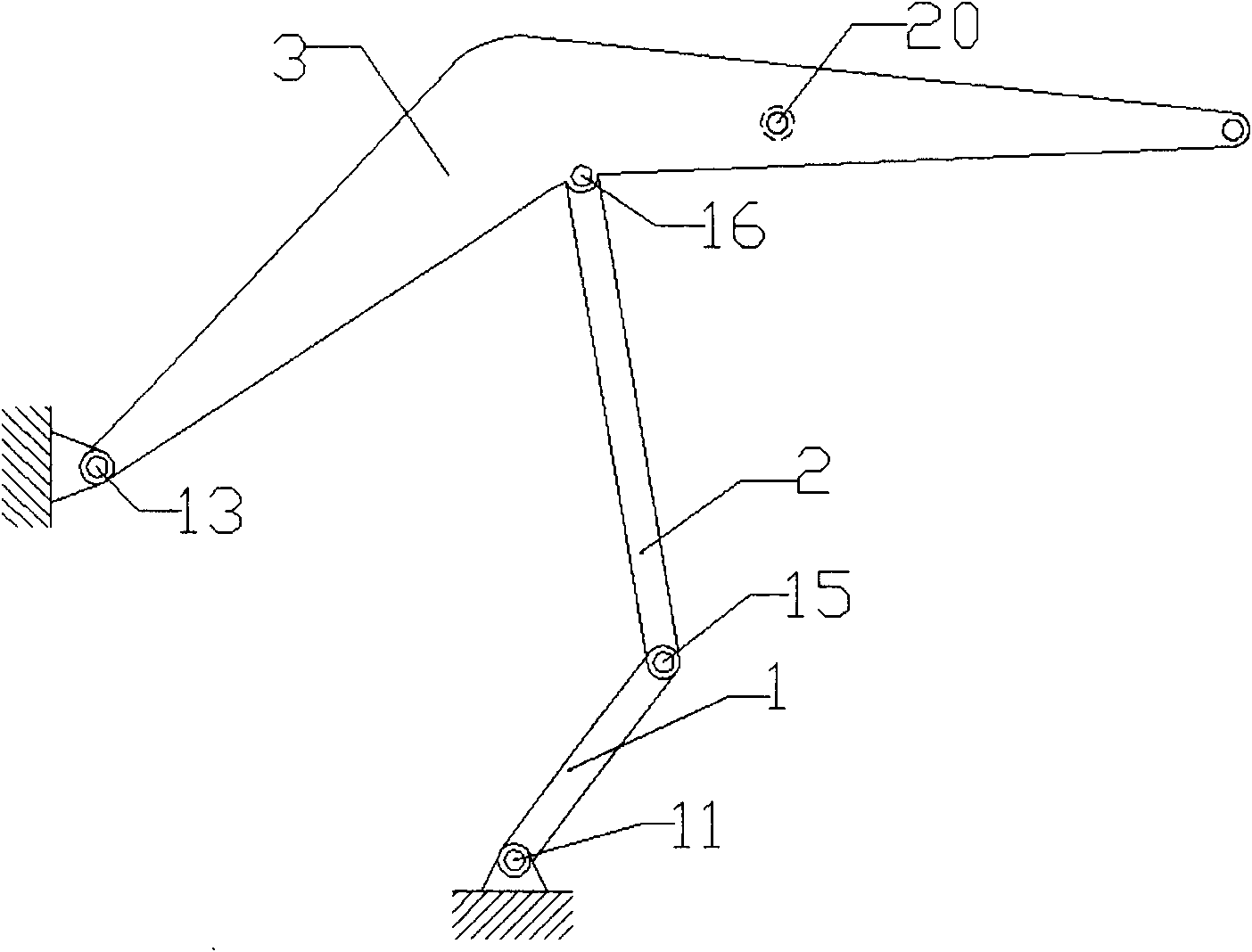

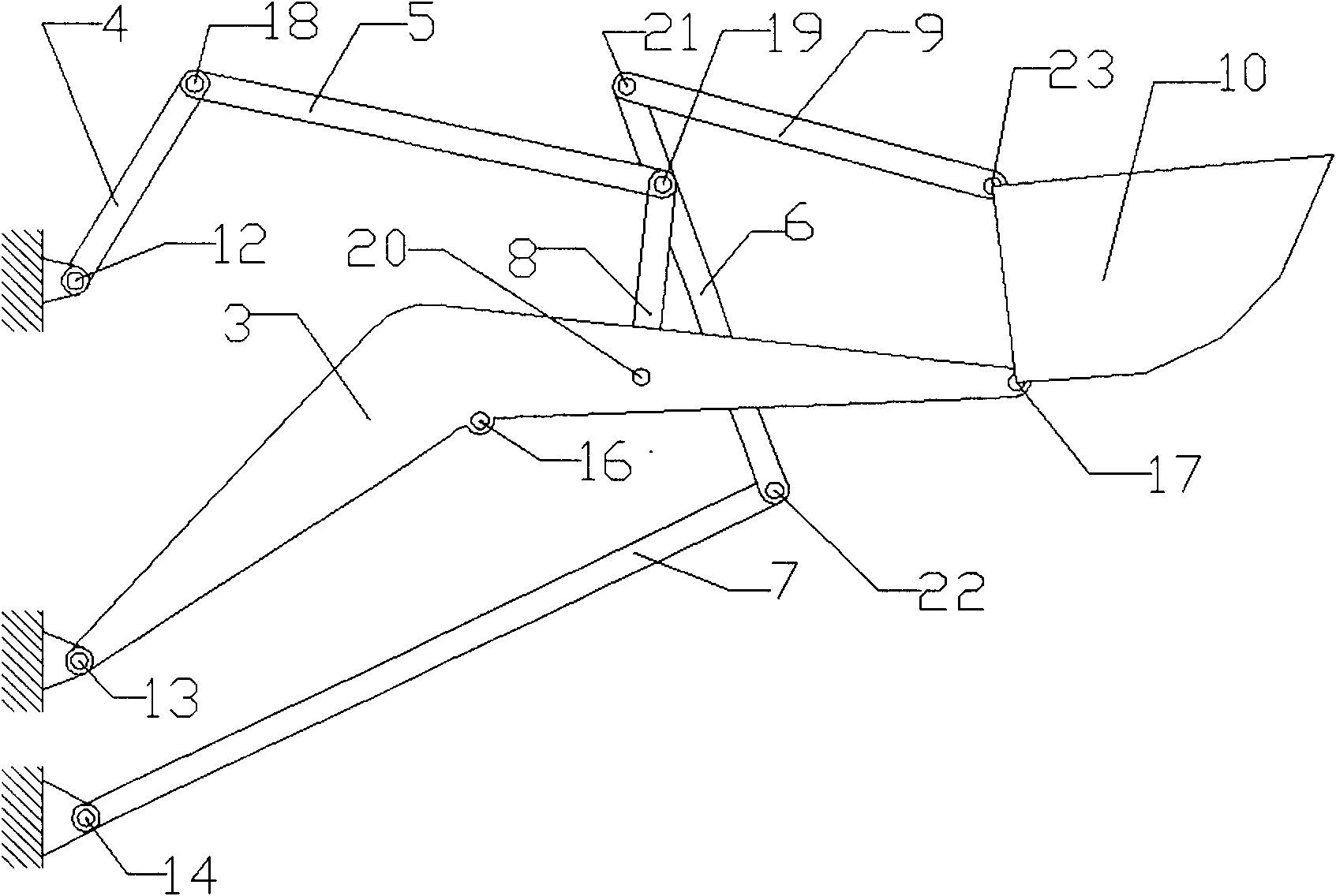

[0023] control figure 1 and figure 2 , the loading and lifting mechanism is a planar single-degree-of-freedom controllable mechanism, which is composed of a first active rod 1 , a first driven rod 2 , a lifting arm 3 and a frame 24 . One end of the first active lever 1 is hinged with the first driven lever 2 through the fifth hinge hole 15, and the other end is hinged with the frame through the first hinge hole 11, and the other end of the first driven lever 2 is hinged with the sixth hinge hole 16. The lifting arm 3 is hinged, one end of the lifting arm 3 is hinged on the frame through the third hinge hole 13 , and the other end is hinged with the bucket 10 through the seventh hinge hole 17 . The first active rod 1 is controlled by the servo motor 27, and the lifting and lowering of the front end of the lifting arm 3 in the working space is realized through programming.

[0024] control figure 1 , 3 , 4 and 5, the bucket turning mechanism consists of the second active ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com