Double-color cake tray and manufacturing method thereof

A production method and cake technology, which can be applied to table utensils, home utensils, table utensils, etc., can solve the problems of monotonous shapes, low market competitiveness, lack of novelty, etc., and achieve the effects of increasing interest, easy production, and beautiful and novel appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

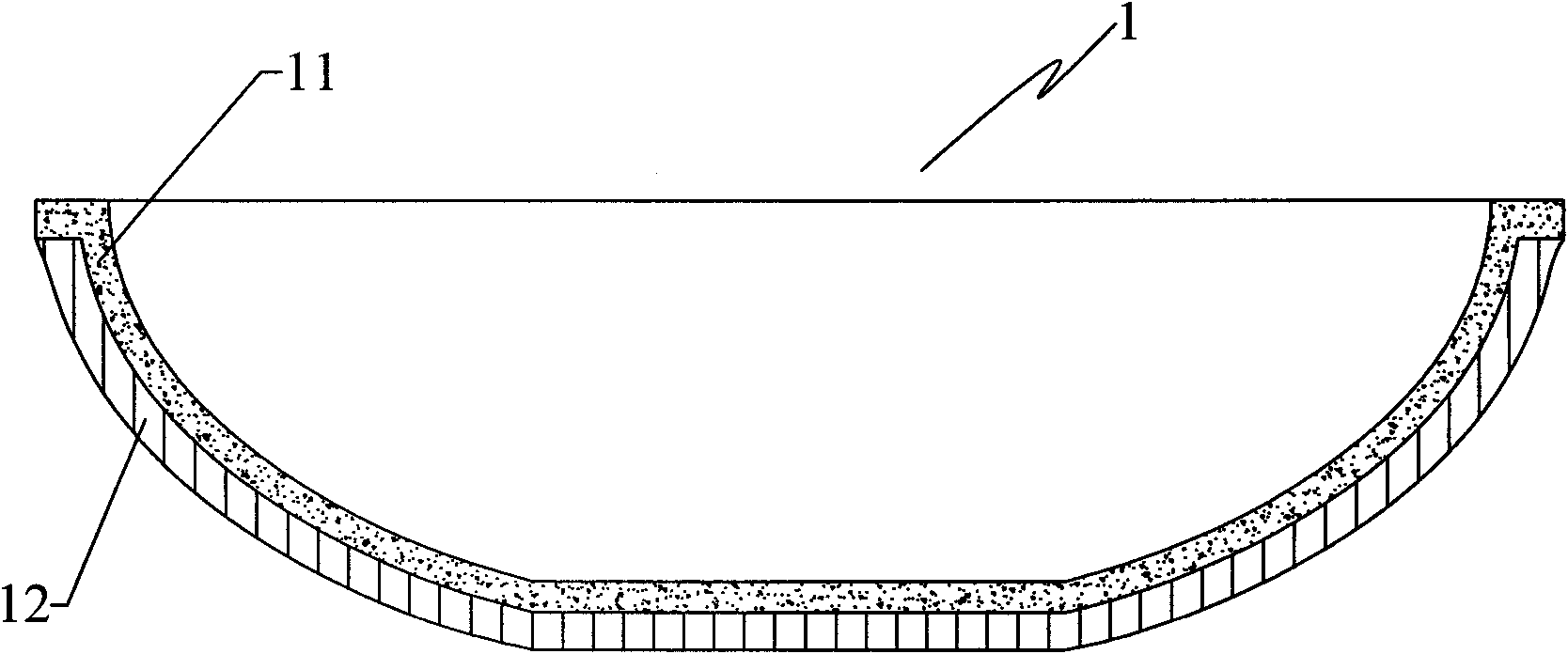

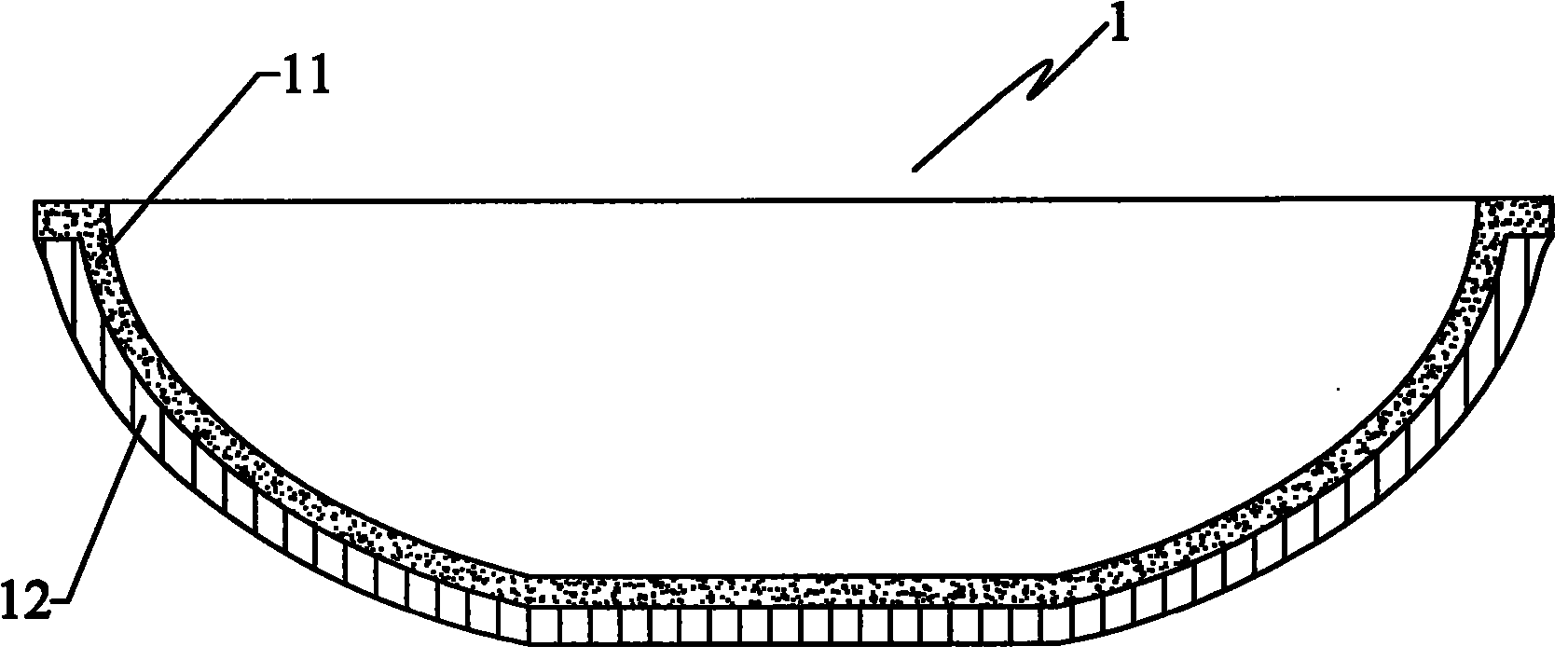

[0021] like figure 1 As shown, the two-color cake pan 1 of the present invention includes an integrally formed upper and lower two-layer pan body 11, 12, and the colors of the upper and lower two-layer pan bodies 11, 12 are different. The production method includes the following steps: a. mold debugging and preheating; b. mixing the raw materials of the first heavy cake pan, mixing solid silica gel and vulcanizing agent according to a certain proportion, and then adding a certain proportion of color cake to carry out mixing Refining until the color is uniform; mix the raw materials of the second cake pan, mix liquid glue A and glue B in a certain proportion, then add a certain proportion of color paste different from the color of the cake, and knead until the color is uniform; c 2. Make the first heavy cake pan, put the mold upright and install it, the upper mold is at the top, and the lower mold is at the bottom, put the kneaded first heavy cake pan raw material into the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com