Bilaterally rotary gas lubrication non-contact mechanical seal device

A mechanical sealing device and gas lubrication technology, applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of poor sealing effect, low bearing capacity, small use range, etc., to achieve good sealing, strong bearing capacity, Use a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

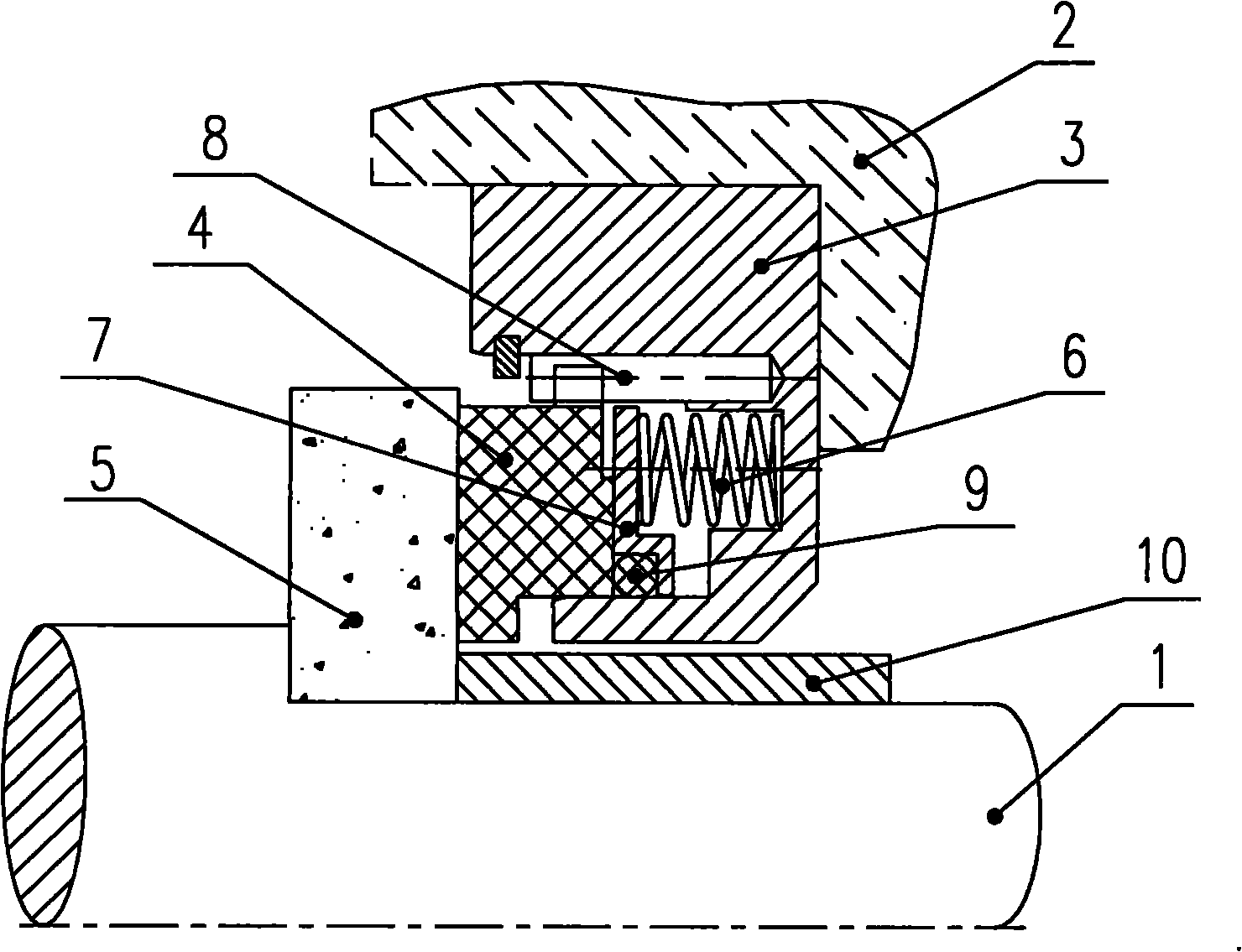

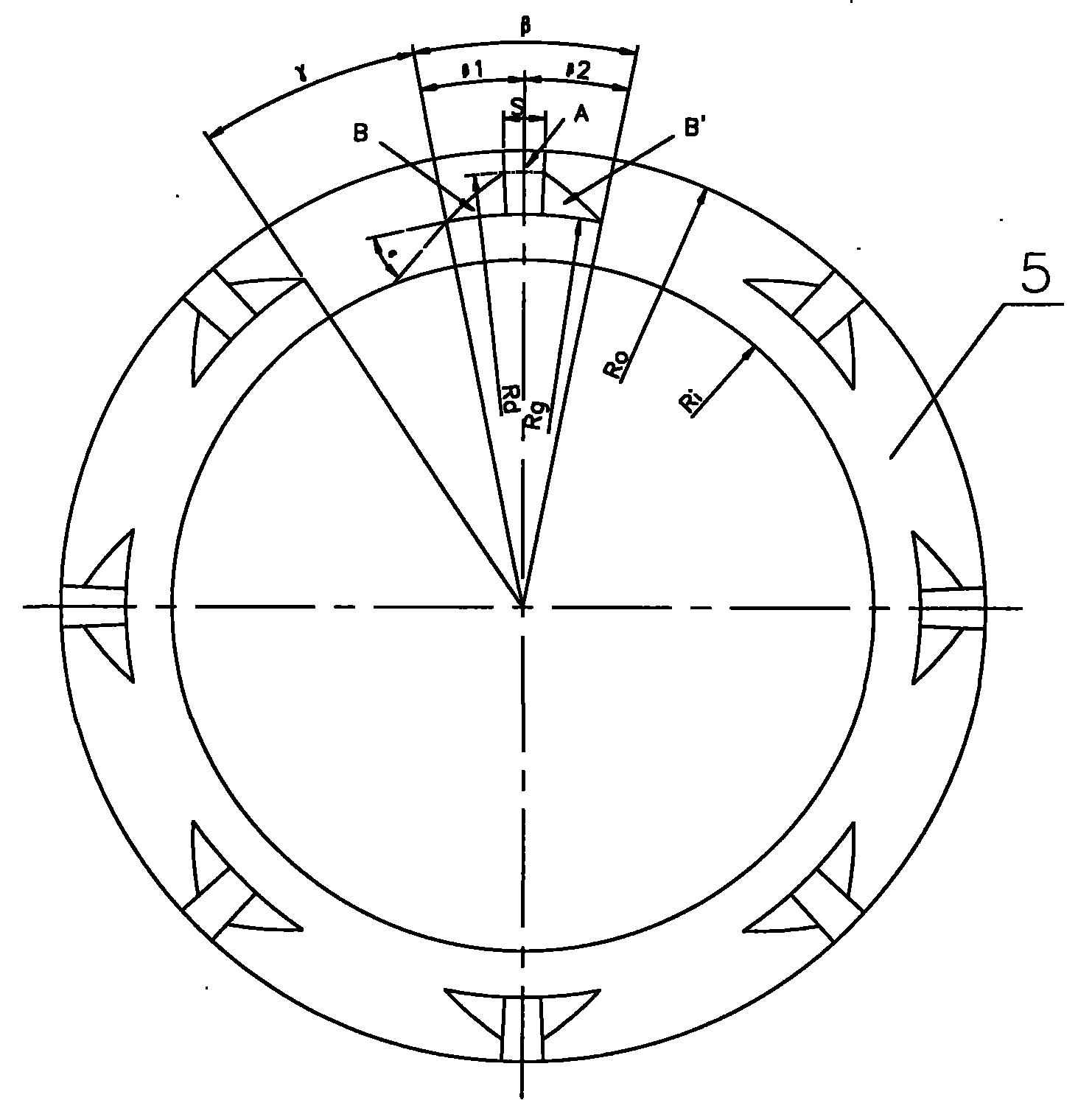

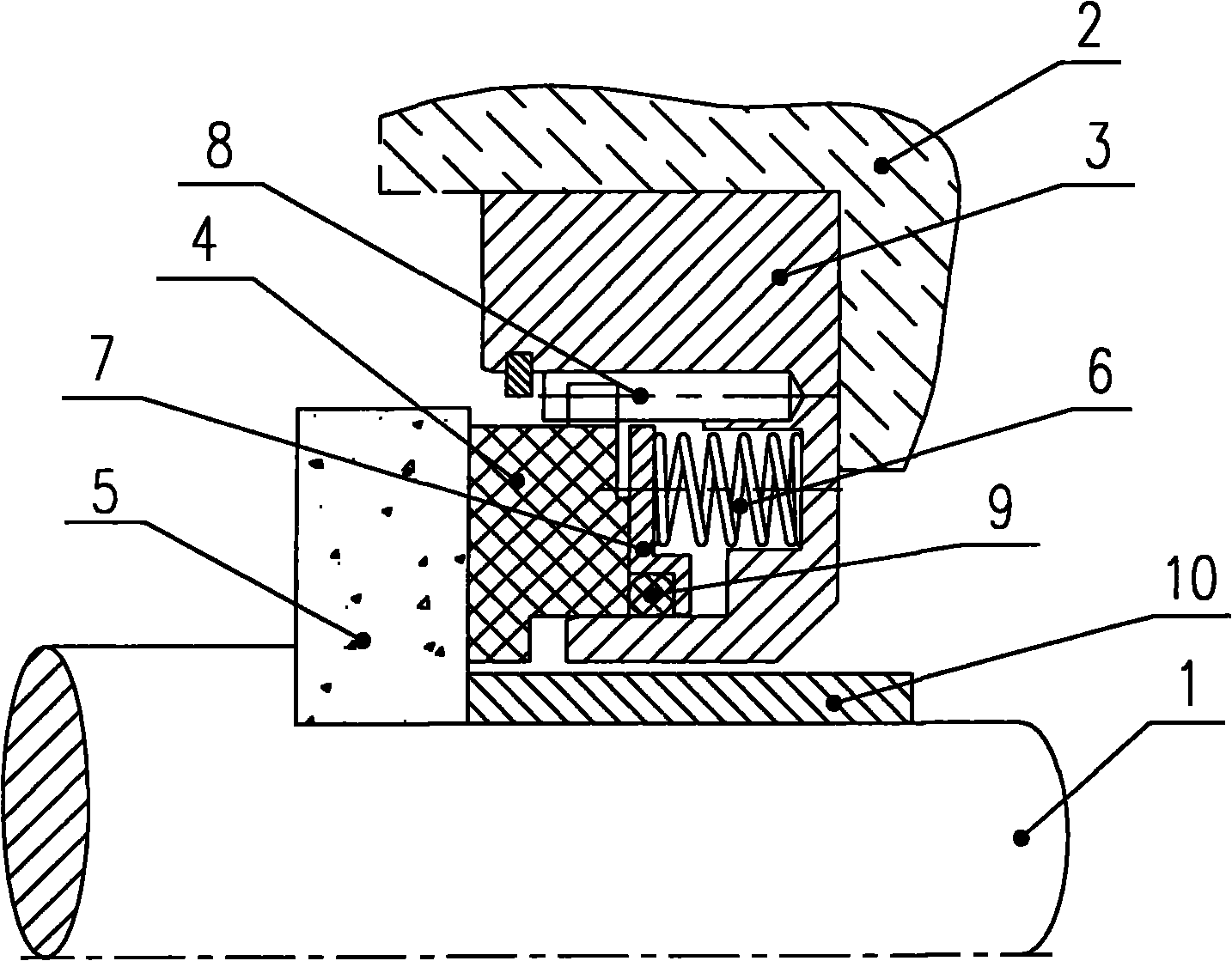

[0029] A gas-lubricated non-contact mechanical seal device that can rotate in both directions, including a sealing chamber, a moving ring, a static ring, a sealing ring, an elastic element, a push ring, and a fixed assembly; In the sealed space, the sealing chamber 3 is placed in the casing 2 of the rotating machine, and the rotating shaft 1 passes through the hole of the sealing chamber 3; the fixing assembly 10 fixes the moving ring 5 on the rotating shaft 1, and the static ring 4 and the moving ring 5 fit, the elastic element 6 is located between the sealing cavity 3 and the push ring 7, the push ring 7 is attached to the back of the static ring 4, and the static ring 4 and the moving ring 5 are attached to each other under the elastic force of the elastic element, The two mating surfaces are sealing end faces, and the sealing ring 9 is installed between the static ring 4 and the push ring 7 to prevent the sealed fluid from leaking through here; the cylindrical pin 8 fixed o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com