Method for producing granular monoammonium phosphate with raffinate

A technology of monoammonium phosphate and raffinate acid, which is applied in the direction of ammonium orthophosphate fertilizer, alkaline orthophosphate fertilizer, phosphate fertilizer, etc. It can solve the problems of excessive water content of products and insufficient nitrogen content of products, so as to increase concentration and reduce steam consumption , Increase the effect of product strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0017] Adopt the method of the present invention, promptly adopt P first 2 o 5 Raffinic acid and P with a mass fraction of about 40% 2 o 5 Dilute phosphoric acid with a mass fraction of about 25% is mixed according to a ratio of 15 to 18:1 to obtain a complex acid; then neutralize the complex acid with ammonia to control the neutralization degree of the reaction slurry to 1.05 to 1.20; The slurry is concentrated, and finally sprayed and granulated to make granular monoammonium phosphate.

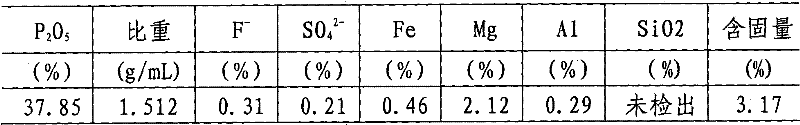

[0018] The quality of raffinate used for acid preparation

[0019]

[0020]

[0021] The quality of wet dilute phosphoric acid used for acid preparation

[0022]

[0023] The quality of blended acid

[0024]

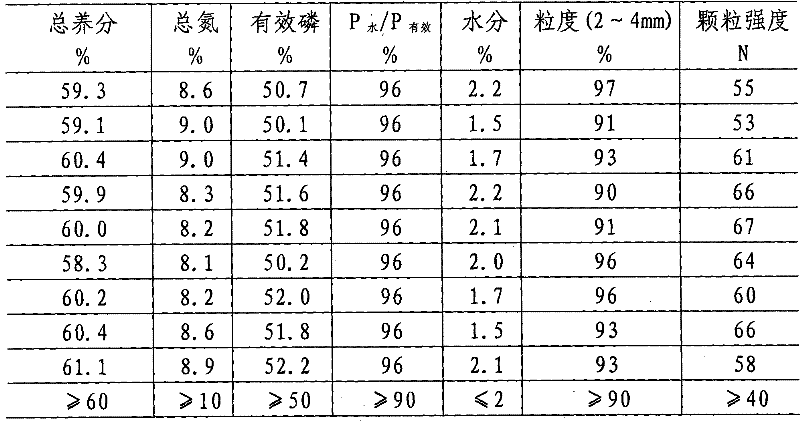

[0025] The quality of granular MAP produced with acid

[0026]

[0027] Phosphate ammonification neutralization degree is controlled at 1.05-1.20.

[0028] Through acid adjustment with wet-process phosphoric acid and raffinate acid, the metal ion content in the ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com