Rotary flat-bed printing machine

A technology for printing presses and lithography, applied in the field of rotary lithographic printing presses, can solve the problems of contamination of the wetting medium roller, ink blockage, unevenness of difficult-to-wet medium, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

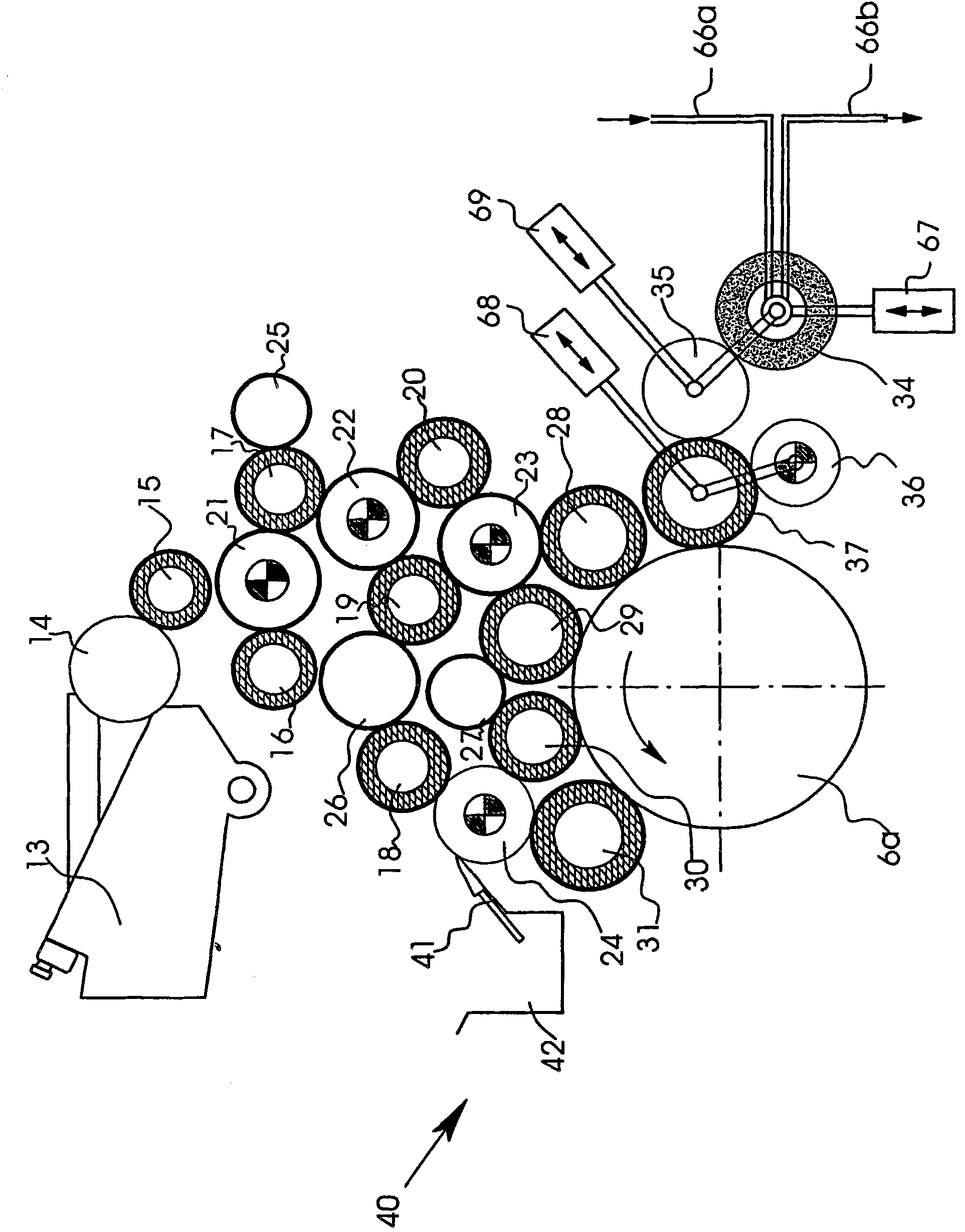

[0036] exist figure 1 The sheet-fed offset printing machine 1 shown in a tandem configuration has a feeder 2 and four printing units 7a-d for the four primary colors black, yellow, magenta and cyan, the unprinted sheet stacks 3 is located in the paper feeder. The delivery 12 of this printing press follows the fourth printing unit 7d. The gripper bridges run around in this delivery with the aid of chain guides. These gripper bridges receive the printed sheets and guide them to the sheet stack, where they are laid down.

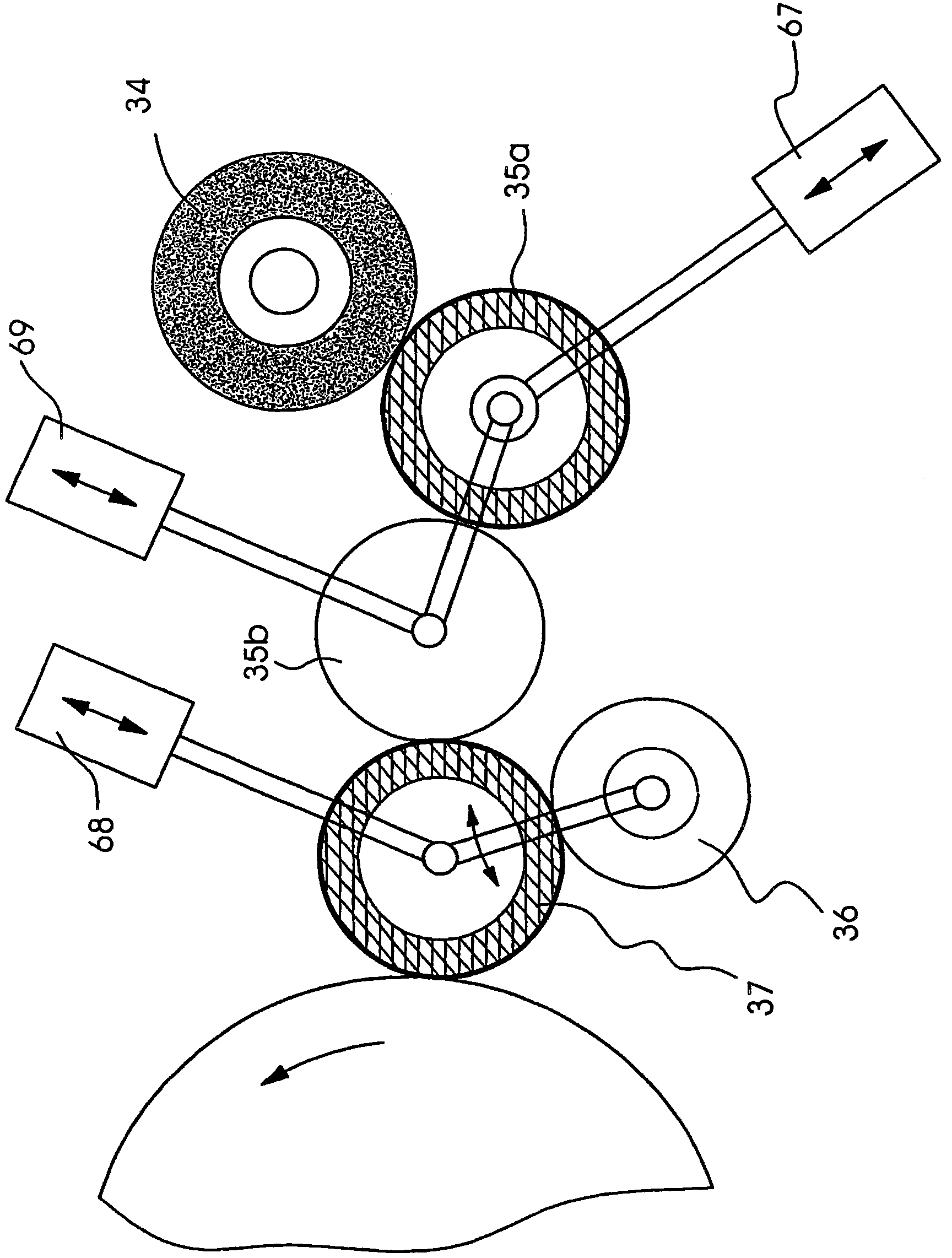

[0037]The printing unit 7 a has an impression cylinder 4 a , a blanket cylinder 5 a and a printing form cylinder 6 a , on which the corresponding printing form is tensioned. Correspondingly, the same is true for the other three printing units 7b-d. The printing plates are inked with inking units 8a-d, the rollers of which cover a large part of the cylinder circumference of the plate cylinder. The four rollers of the dampening device 9a are connected to co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com