Water-cooled motor and anti-tympanites method of water-cooled end cover body of water-cooled motor

A technology for electric motors and water coolers, applied in the field of electric motors, can solve the problems of easy occurrence of virtual welding, scrapping of water-cooled end caps, and small contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

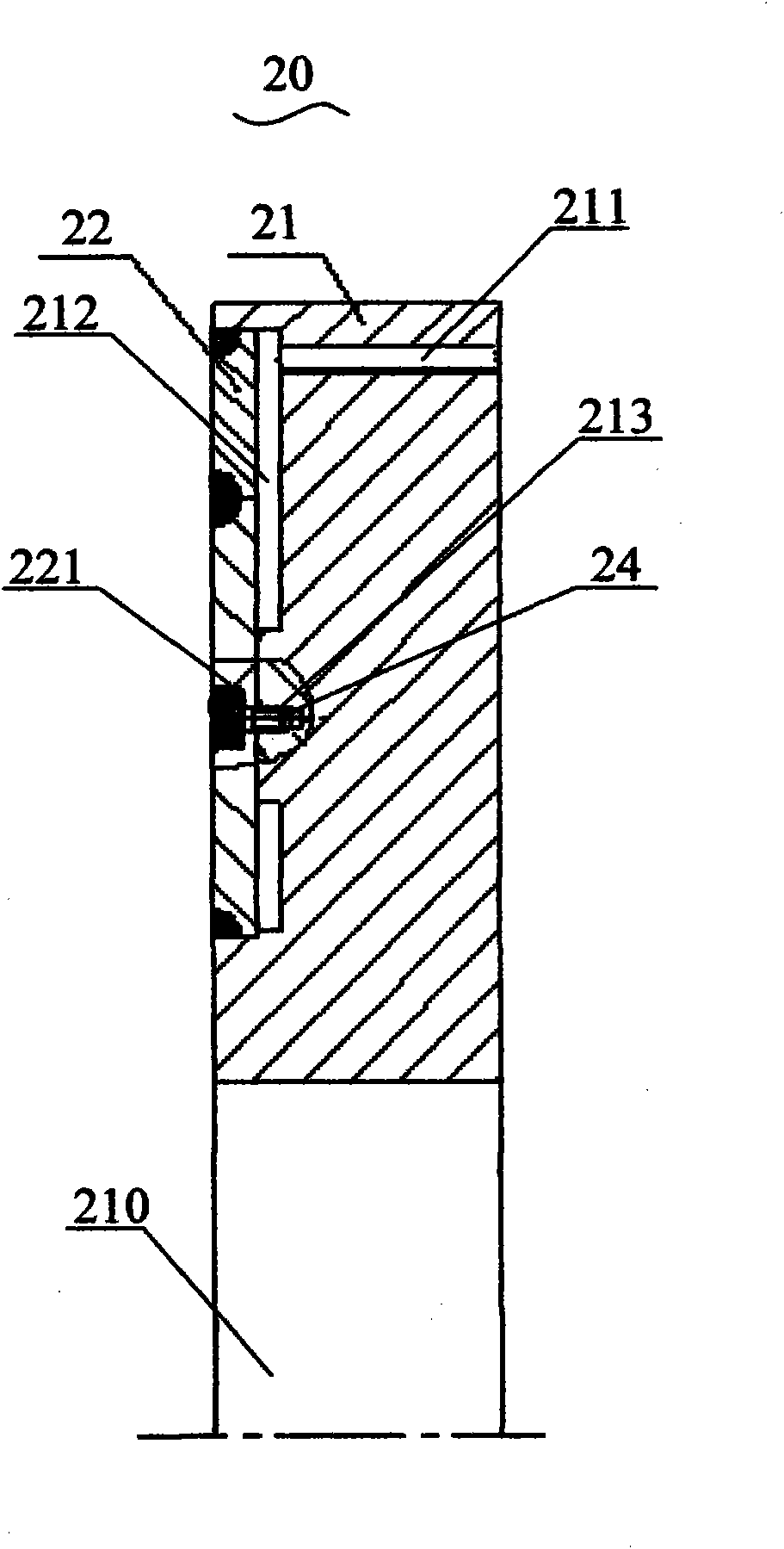

[0016] Please see figure 2 , which is a schematic structural diagram of a water-cooled end cover body 20 of a water-cooled motor in a preferred embodiment. The water-cooled motor water-cooled end cover 20 is provided with a ring water tank, and the external circulating water flows through the water-cooled motor water-cooled end cover 20 and the ring water tank of the water-cooled motor casing to take away the heat generated by the motor during operation. This reduces the temperature of the motor. Wherein, a stator is fixed inside the water-cooled casing.

[0017] Specifically, the water-cooled end cover body 20 includes a water-cooled end cover 21 , a ring water tank cover plate 22 and bolts 24 .

[0018] The center of the water-cooled end cover 21 is formed with a shaft hole 210 matched with the rotor shaft of the water-cooled motor. The water-cooled end cover 21 is also formed with a ring water groove 212 concentric with the shaft hole 210 and a water guide hole 211 conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com