Fast measuring method of right angle of large-sized rectangular glass substrate and measuring instrument thereof

A glass substrate, large-scale technology, applied in measurement devices, instruments, optical devices, etc., can solve the problems of high cost, measurement errors, scrapped glass substrates, etc., to achieve high efficiency and simple operation, convenient observation and reading, convenient and fast cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

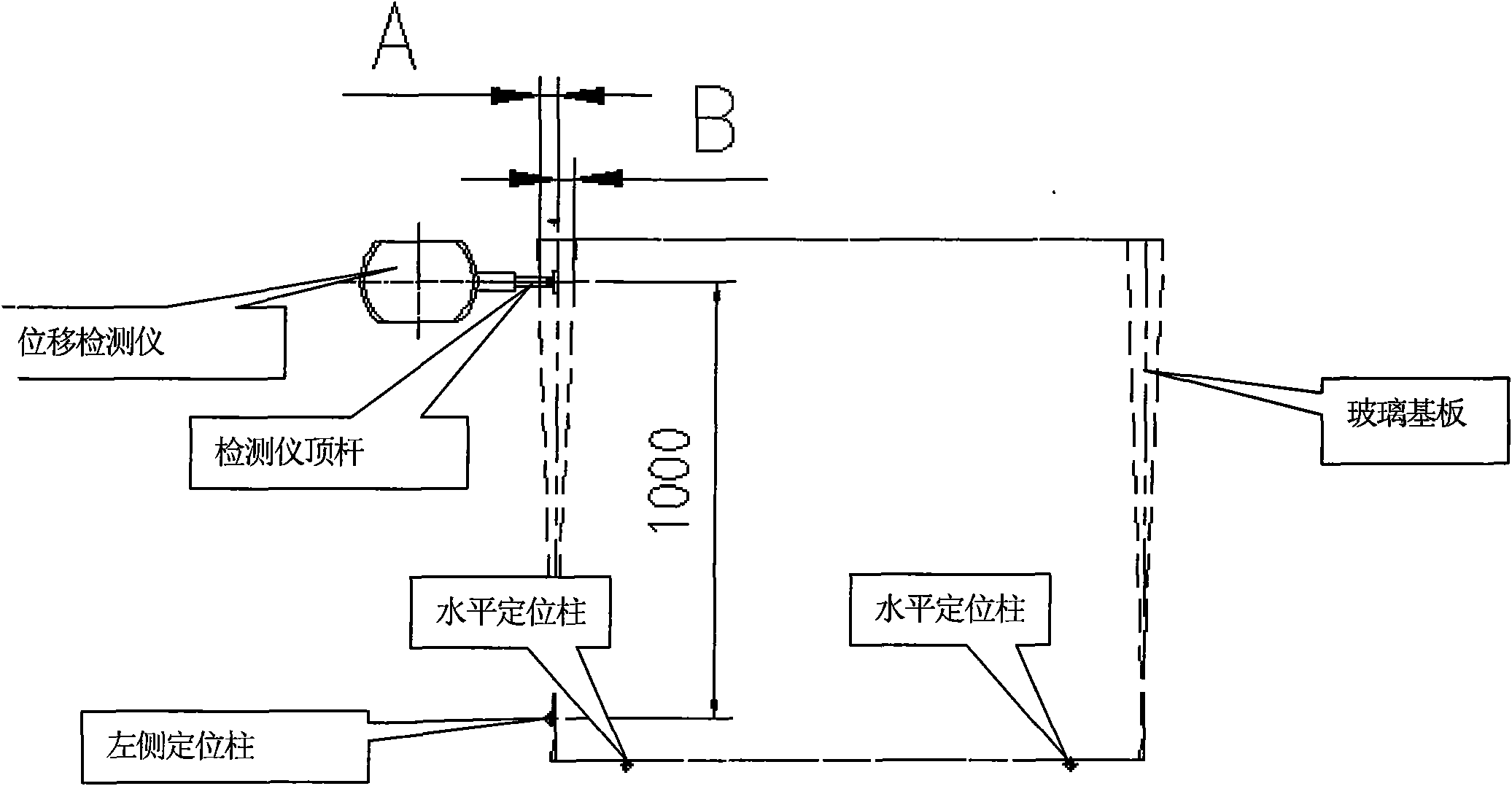

[0026] as attached figure 1 The inventive method shown is:

[0027] First, when measuring, place one side of the glass substrate directly on the two positioning columns set at the bottom, and make the left edge of the glass close to the positioning column set on the left side. At this time, the displacement of this side is measured by a displacement detector. Data d1 (mm), the reference point of the displacement detector is set at 1000mm vertically above the left positioning column;

[0028] Then, turn the large-size glass over 180°, that is, turn the glass over, and measure the corresponding side of the first measurement side through the displacement detector. The measured value is d2 (mm), and finally calculate: the absolute value of (d2-d1) 1 / 2 of is the right angle measurement data of the large-size glass substrate.

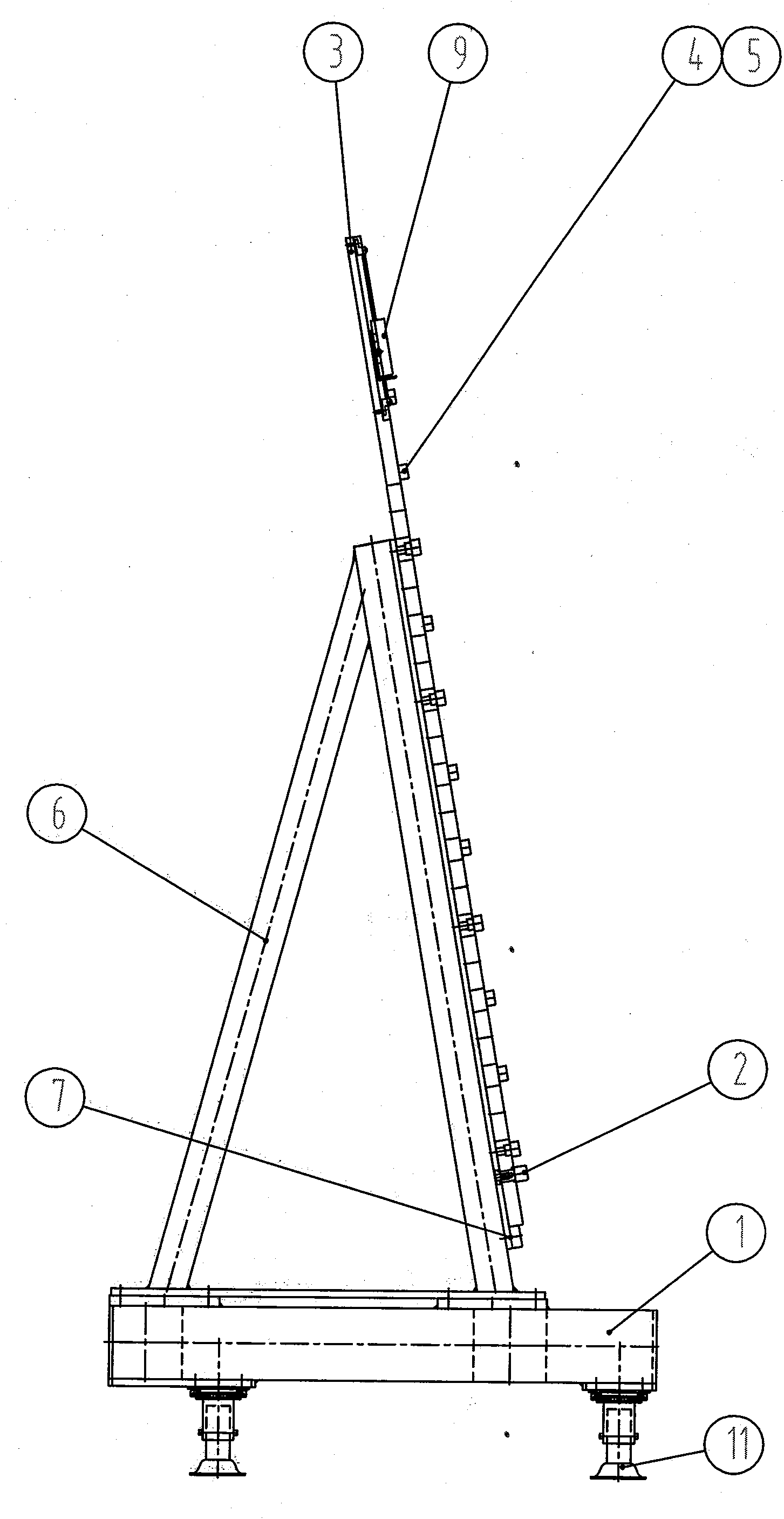

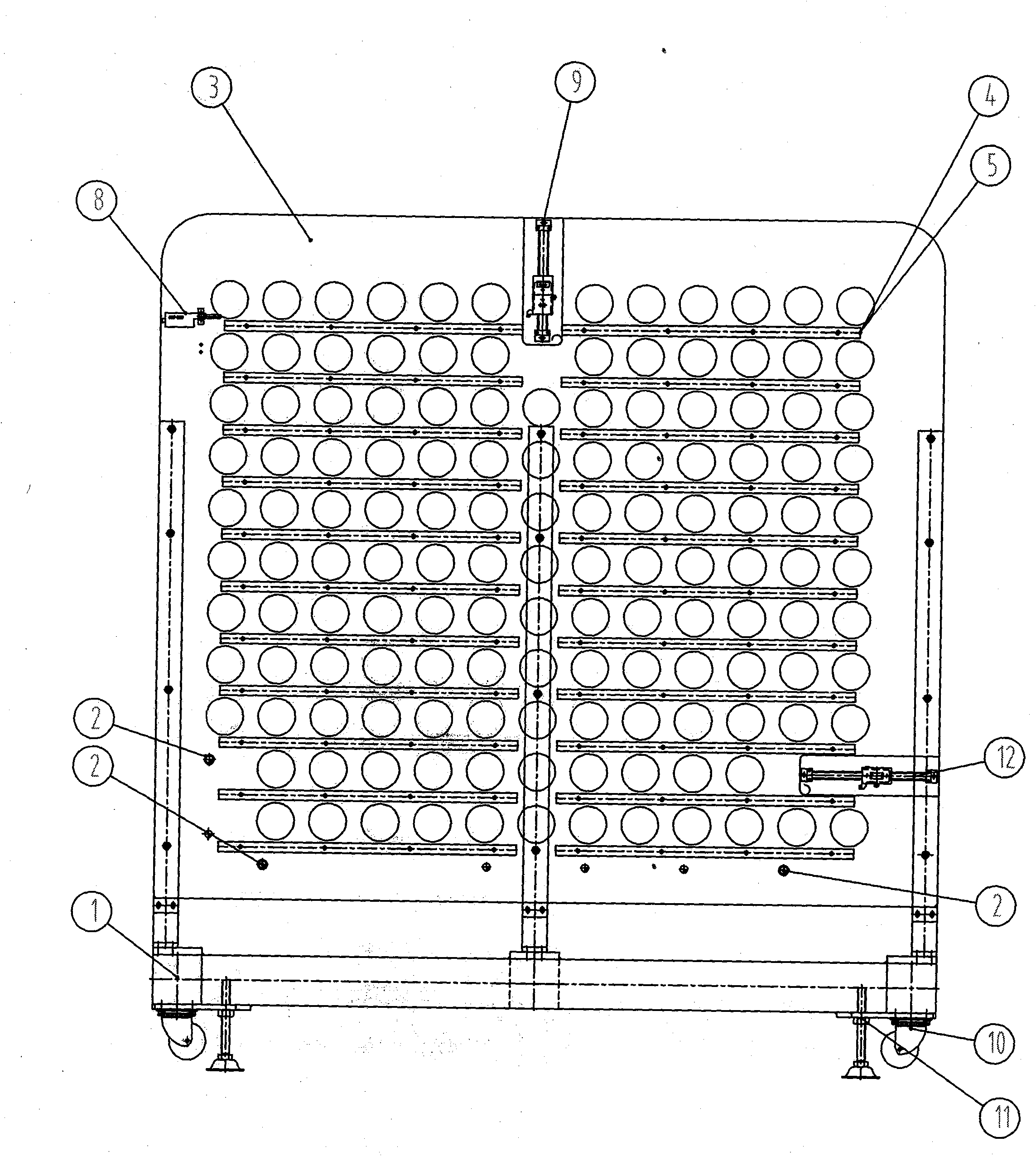

[0029] as attached figure 2 , 3The measuring instrument for the right angle rapid measurement of the large-size glass substrate of the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com