Shell ring assembly device for assembly of tower body of wind power generation iron tower

A technology for tower body and power unit of iron tower, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

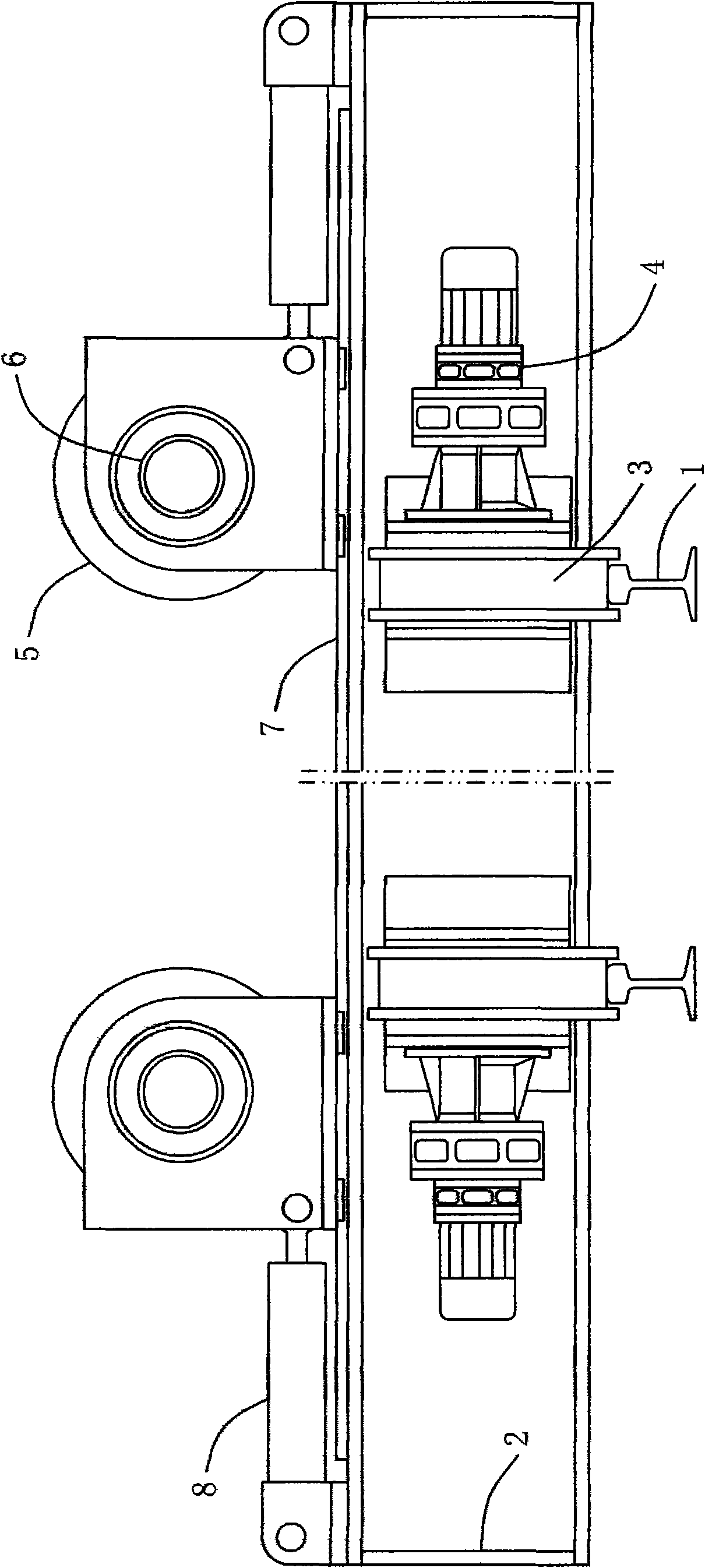

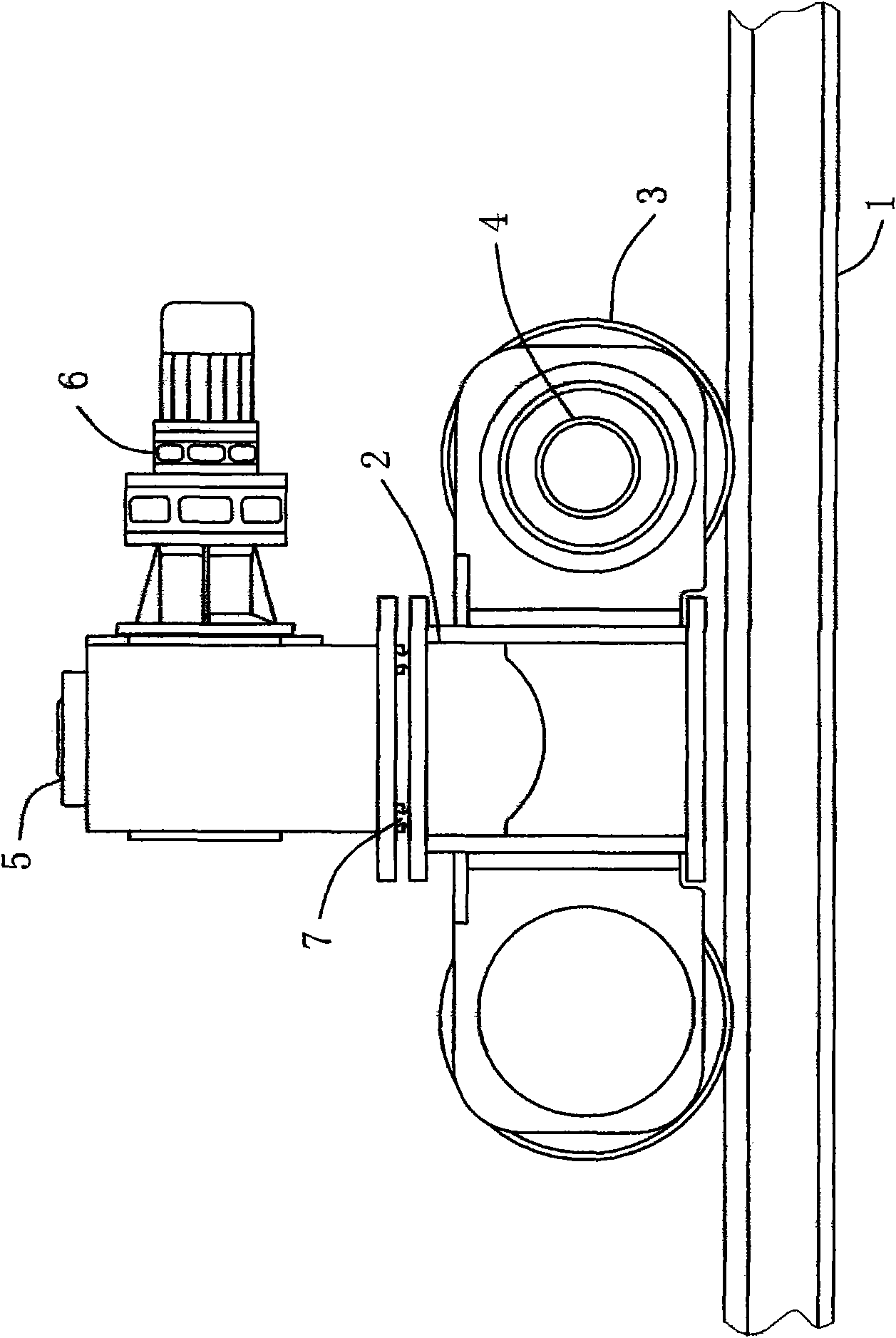

[0027] Such as figure 1 , figure 2 and Figure 4 As shown, a barrel joint pairing device for wind power tower body assembly includes at least two groups of pairing units that are slidably installed on horizontal rails 1; The roller frame 2 on the roller frame 2 is provided with a roller 3 matching with the horizontal track 1, and the roller frame 3 is arranged on two sides of the roller frame 2 or the bottom surface of the roller frame 2, and the roller frame The upper end surface of 2 is provided with a slide rail 7, which is perpendicular to the extension direction of the horizontal rail 1; two runners 5 for supporting the cylinder joint, and the two runners 5 are mounted on the on rail 7.

[0028] The two runners 5 are respectively connected with a force applying device, the force applying direction of the force applying device is consistent with the extension direction of the slide rail 7, one end of the force applying device is hinged on the roller frame 2, and the ot...

Embodiment 2

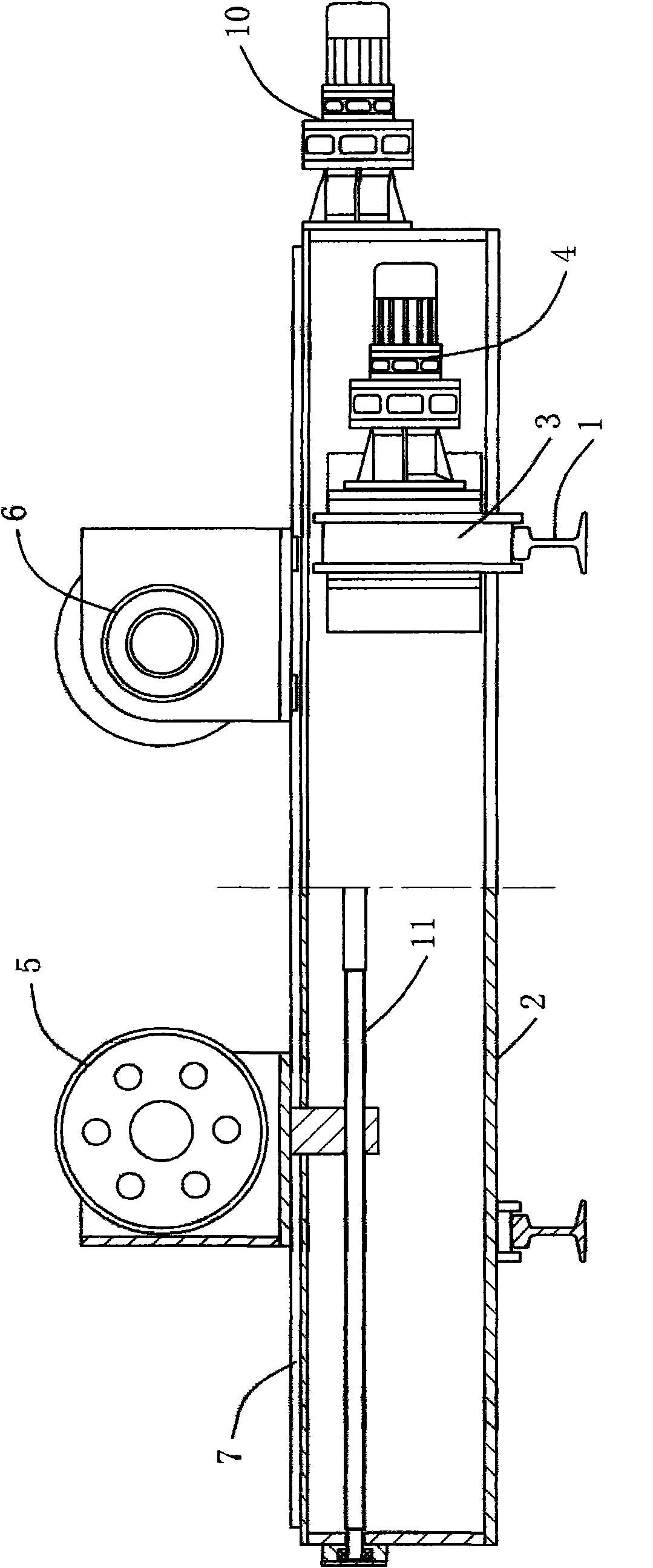

[0033] Such as image 3 As shown, a barrel joint assembly device for wind power generation iron tower tower body assembly, its structure is basically the same as that of Embodiment 1, the difference is that: the two runners 5 are respectively threaded to be driven by the first power device On the screw 11, the screw 11 is rotatably mounted on the roller frame 2, the screw 11 is consistent with the extension direction of the slide rail 7, the screw 11 is provided with forward and reverse threads, the first power unit It is preferably the first motor reducer 10 .

[0034] Considering the frequency of use and cost, the first power unit can be replaced by a hand wheel, and the center height of the barrel joint can be adjusted by manually operating the distance between the two runners 5 .

[0035] It works as follows:

[0036] Such as Figure 5 and Figure 6 As shown, four groups of pairs of units are arranged on the horizontal track, which are successively the first group of p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com