Direct current permanent magnetic upper wheel motor

A permanent magnet type, sky wheel technology, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit static parts, etc., can solve the problems of inconvenient maintenance, mechanical friction loss, waste of electric energy, etc., to extend the maintenance period, save The effect of reducing power and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited by the embodiments.

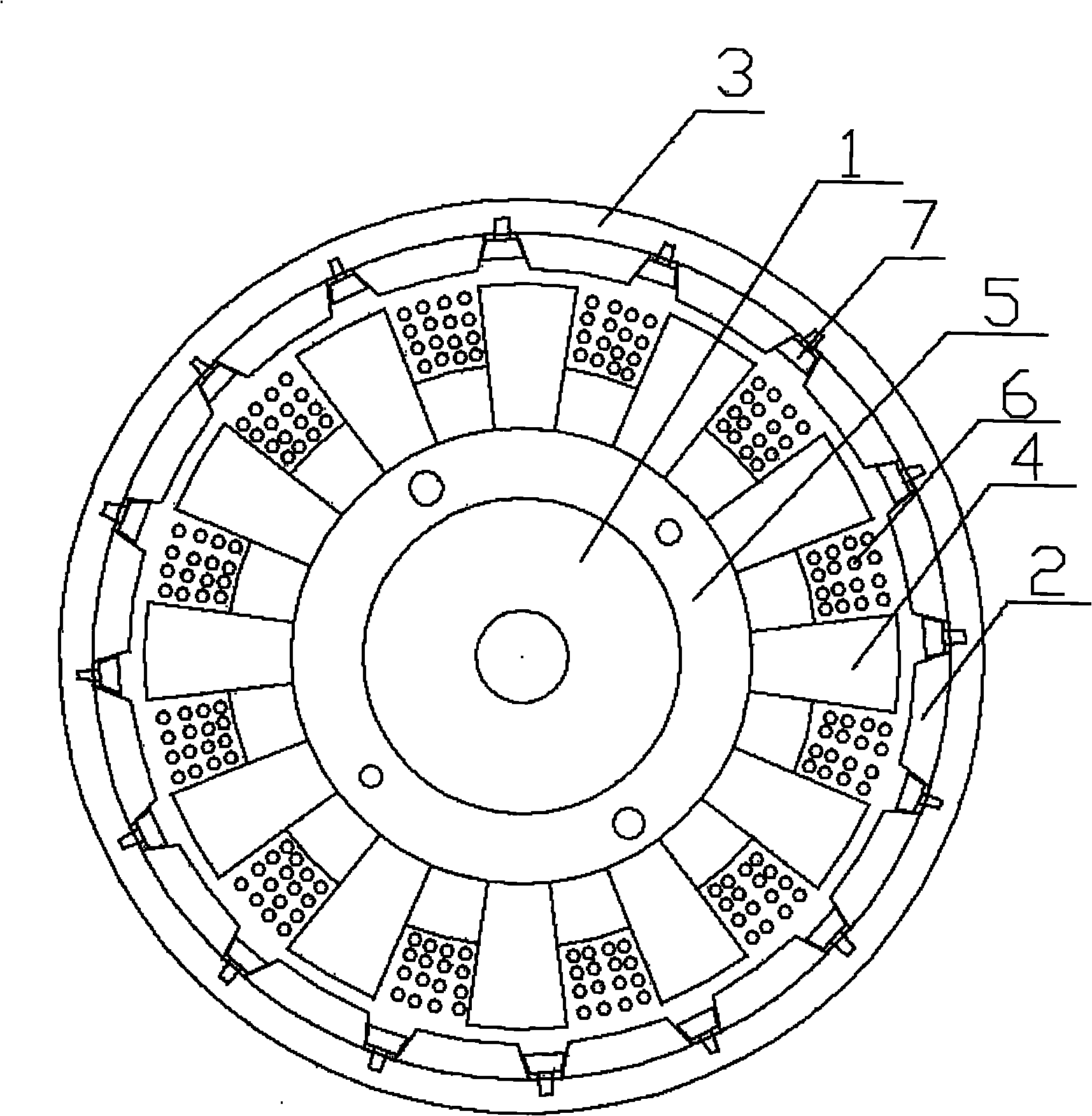

[0015] As shown in the figure, a DC permanent magnet sky wheel motor of the present invention is composed of the following structure: the stator silicon steel sheet 4 is fixed on the main shaft through the stator inner ring locking sheet 5, and the stator silicon steel sheet 4 is wound with a coil winding 6 , there is a permanent magnet 2 between the stator silicon steel sheet 4 and the outer rotor ring 3, three stator silicon steel sheets 4 and four permanent magnets 2 form a group, and the distance between the top surfaces of adjacent permanent magnets 2 is the same Half of the distance between adjacent stator silicon steel sheets 4, the first stator silicon steel sheet 4 in each group is directly opposite to the first permanent magnet 2, the second permanent magn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com