Axial flow pump guide vane body with high specific speed

A guide vane, axial flow pump technology, applied in the direction of the pump, the components of the pumping device for elastic fluid, the pump element, etc. The effect of improving the efficiency of the device, increasing the overflow space, and reducing the hydraulic loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

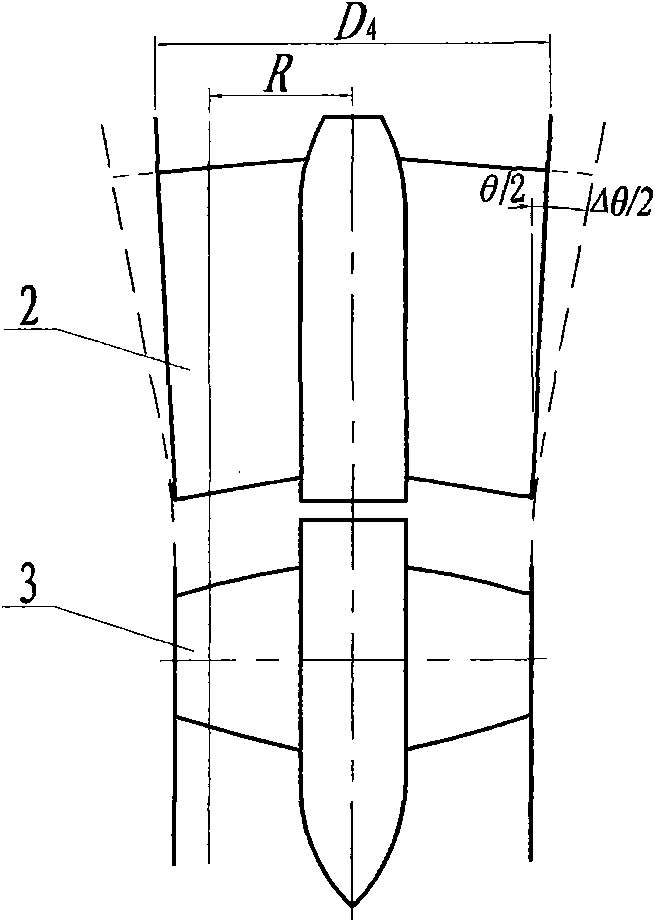

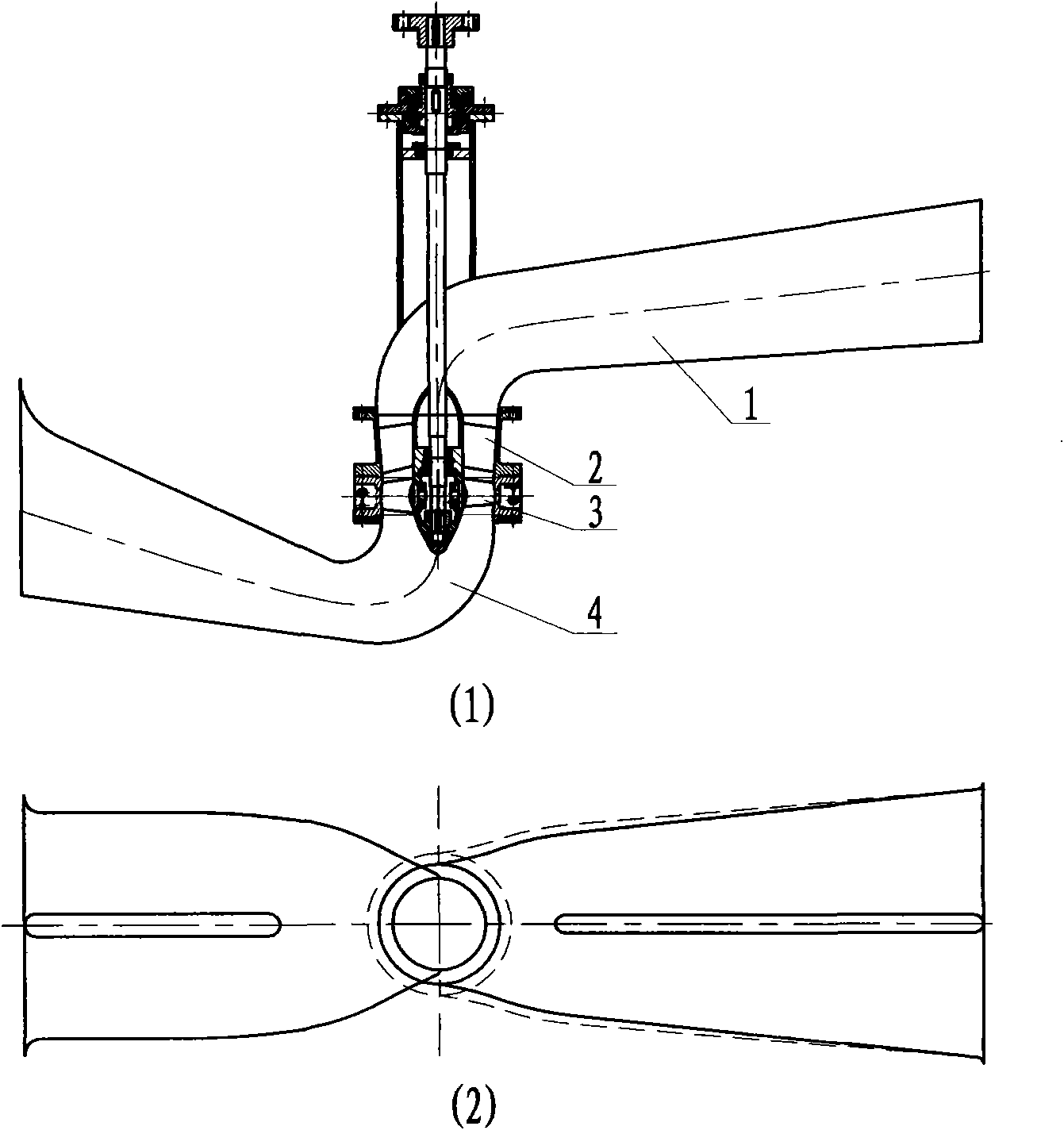

[0029] Embodiment 1, the application of the guide vane body in the vertical axial flow pump device with straight pipe outlet after increasing the diffusion angle, see image 3 shown. Due to the increased diffusion angle of the guide vane body, the diameter of the outlet is increased, which increases the flow space for the subsequent straight pipe outlet flow channel, but does not increase the maximum width of the outlet flow channel, and does not need to increase civil construction investment. Due to the increase of the flow space of the outlet channel and the reduction of the flow velocity, the hydraulic loss is greatly reduced. Since the hydraulic loss of the outlet channel in large-scale low-lift pumping stations accounts for 70% to 80% of the total loss of the inlet and outlet channels, it can be Effectively improve the efficiency of the pump device.

Embodiment 2

[0030] Embodiment 2, the application of the guide vane body in the vertical axial flow pump device with siphon water outlet after increasing the diffusion angle, see Figure 4 shown. Due to the increase of the outlet diameter of the guide vane body, the flow space of the water outlet channel has also been increased, but only the overall width of the gradual expansion section in the front part of the siphon outlet channel has been increased, and the maximum diameter of the flow channel has not been increased. However, the efficiency of the pump device can be effectively improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com