Folding fan-shaped hyperboloidal unit-type building curtain wall system and a construction method thereof

A hyperboloid curtain and hyperboloid technology, which is applied in the direction of buildings, building components, building structures, etc., can solve the problems of increasing costs, increasing costs, and difficulty in waterproofing treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The construction method provided by the present invention, which adopts the fitting of plane unit body plates, that is, forms the fan-shaped hyperboloid unit type building curtain wall system by cold bending on site, is:

[0065] Step 1. Set up the fan-shaped hyperboloid curtain wall structure system on the main body of the building and make the flat unit body:

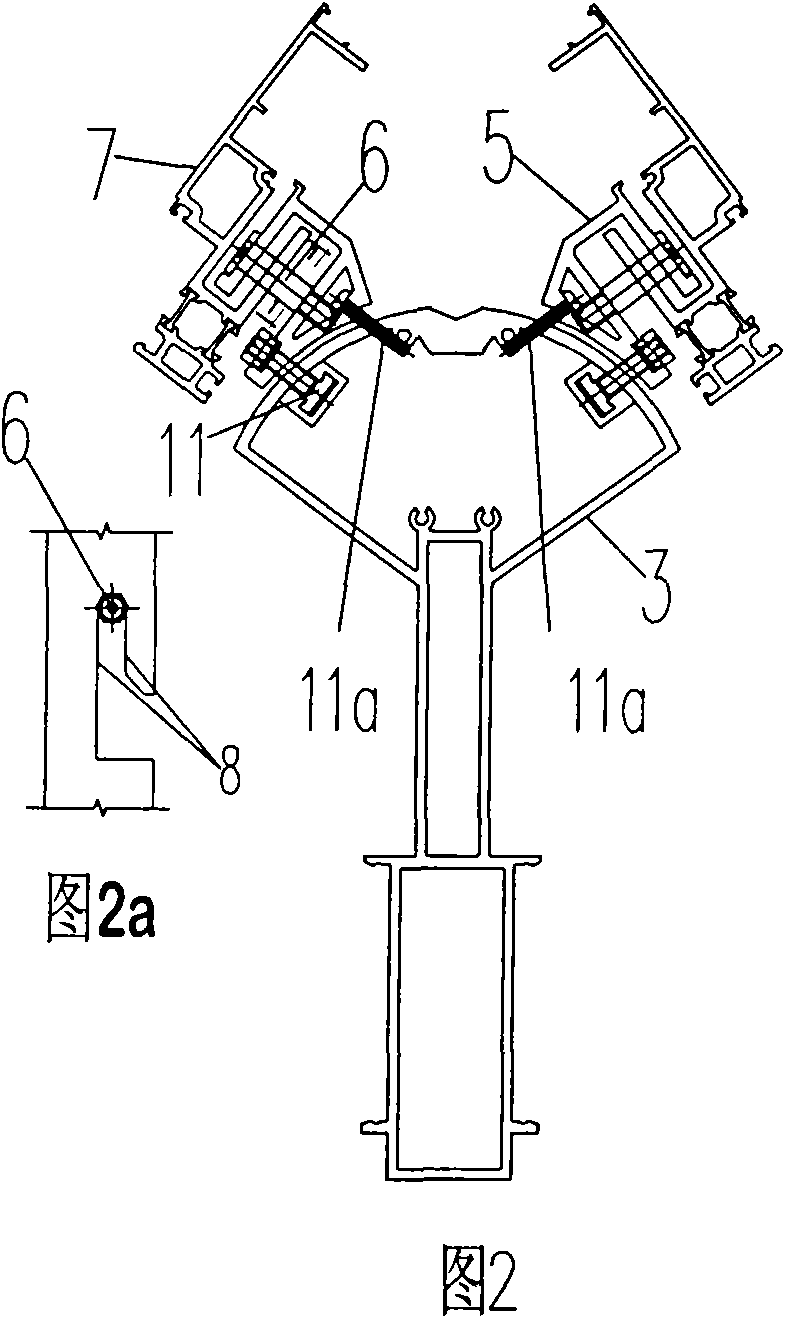

[0066] The project of this embodiment is a construction method for forming fan-shaped hyperboloid unit curtain walls by fitting plane unit blocks. First, a fan-shaped hyperboloid curtain wall structure system is set on the outer wall of the building. The curtain wall system needs to be installed on the side walls of the building. Aluminum alloy columns are set at the yin and yang corners to form the yin and yang curtain wall structural system (see image 3 , 10 ) and sun corner curtain wall structure system (see figure 2 , 4 ). The curtain wall structure system is set on the side of the building, the struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com