Automatic assembling machine of hinge spring shafts

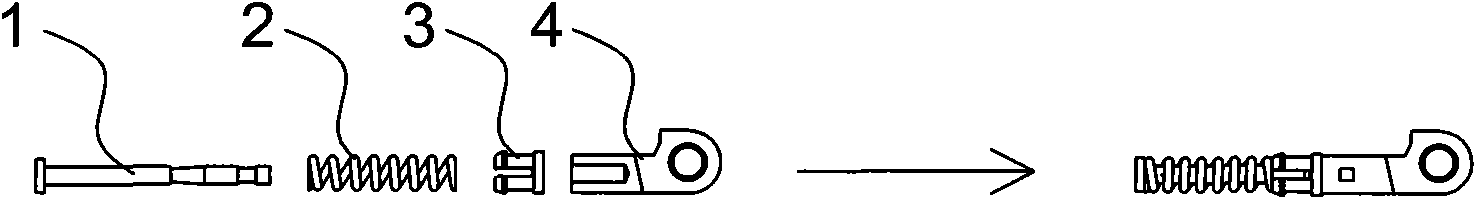

An automatic assembly machine, automatic assembly technology, applied in the direction of assembly machine, optics, instruments, etc., can solve the problems of great influence of the use of eyeglass frames, unstable quality, slow assembly speed, etc., to achieve consistent finished product specifications, fast feeding speed, small difference effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

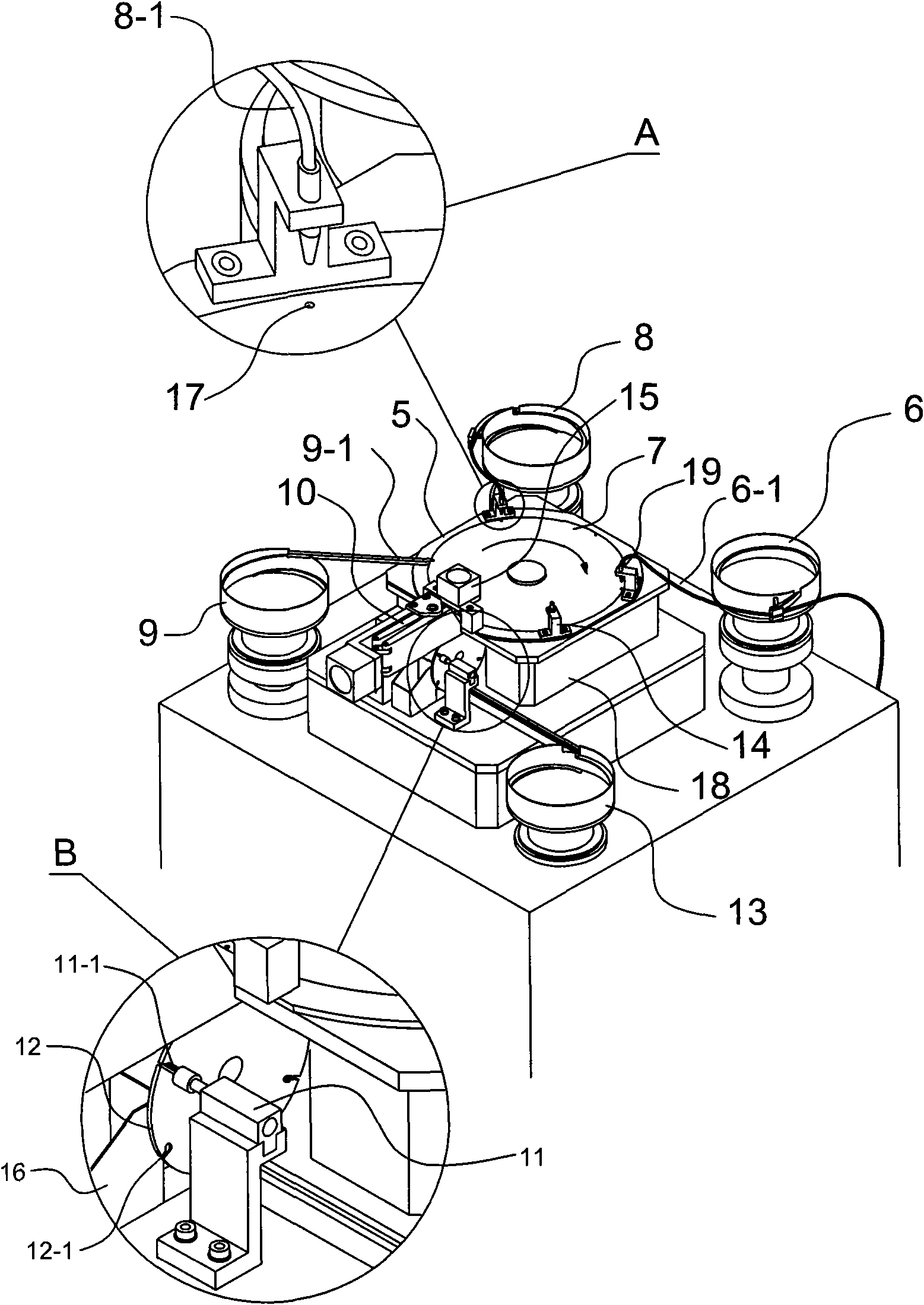

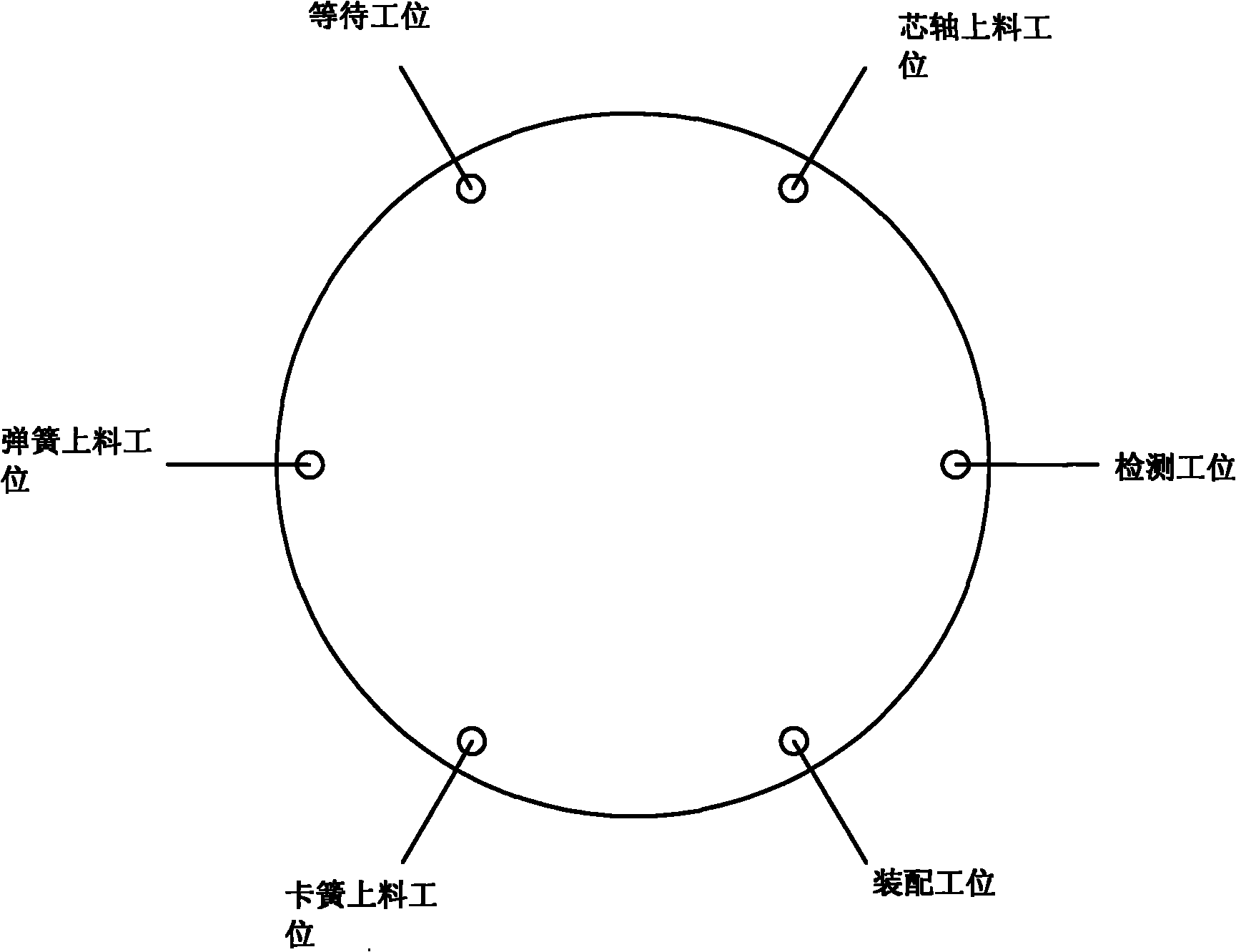

[0020] Such as figure 1 , 2 , 4 and 5, the hinge spring shaft automatic assembly machine includes a base 18, a supporting plate 5 is fixed on the base, and a horizontal large turntable 7 is arranged close to the surface of the supporting plate, and the top of the large turntable extends radially to form an overhang There are six through-holes 17 evenly distributed on the circumferential direction of the convex edge, and the six through-holes correspond to the spring feeding station, the spring feeding station, the waiting station, and the mandrel respectively according to the turning sequence of the large turntable. Loading station, testing station and assembly station (see figure 2 ), the side of the large turntable below the through hole is concave to form an installation accommodation hole, a fiber optic sensor 14 facing the through hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com