Method for improving flexibility of yak decorative fur/leather cutis plate by acid swelling and splitting

A technology of acid swelling and softness, which is applied in the field of leather and fur manufacturing, and can solve the problem that the loosening or lubricating effect of leather collagen fiber bundles cannot be fully exerted, the improvement of the softness of yak decorative fur leather board is not significant, and the problem of yak decorative fur leather Hard board and other problems, to achieve the effect of easy implementation, increased equipment investment, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

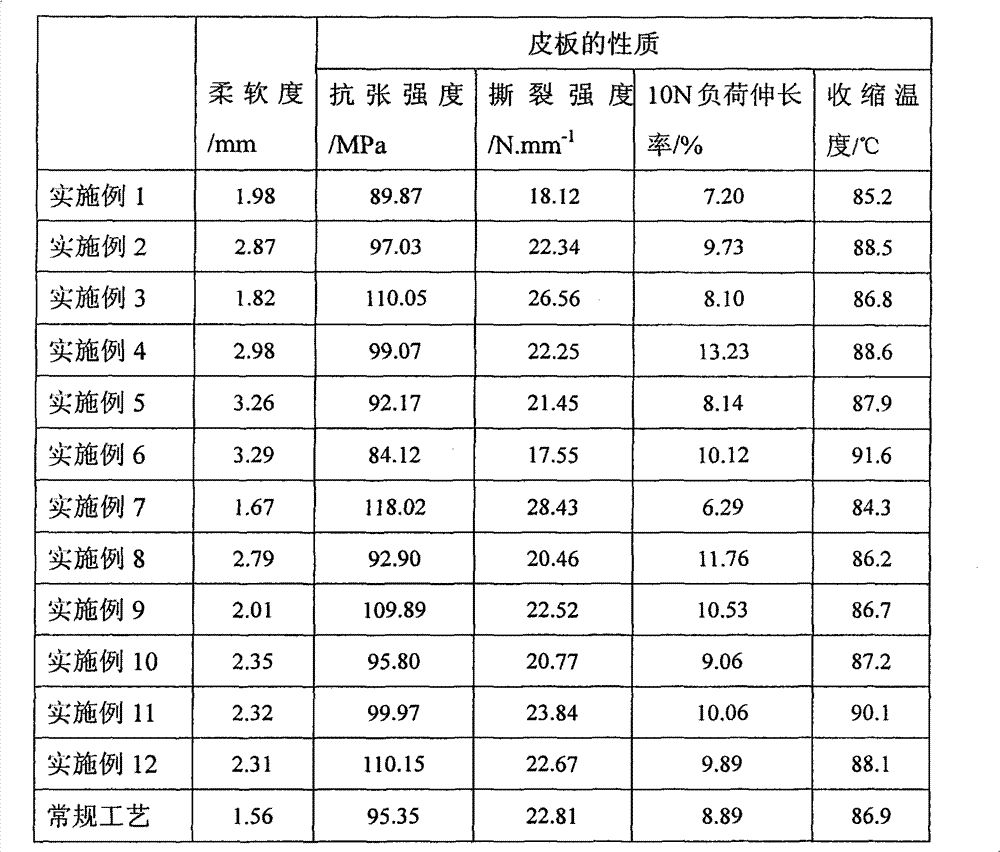

Examples

Embodiment 1

[0022] Put 5 pieces of yak hides that have been soaked in water, degreased and combed into the drum, add water with a liquid ratio of 10 at 20°C, and rotate for 30 minutes; then add sodium chloride and anhydrous sodium sulfate with a mass ratio of 1:1 to make The concentration is 10g / L, and then rotate for 30 minutes; then add formic acid in 4 times at 1.5g / L, 1.0g / L, 1.0g / L, 1.0g / L in unequal parts, each interval is 1.5 hours, Make the final concentration 4.5g / L, during which the drum rotates; after that, the drum rotates at a speed of 4r / min, and stops for 50min every 10min, until the total time of acid swelling reaches 48 hours; the yak hide is taken out from the drum, according to the routine The yak decorative fur fur processing technology carries out combing and finishing, and then performs skinning and controls the thickness of the leather board after the skinning to be 70-75% of the initial thickness of the leather board; after that, conventional follow-up processing ca...

Embodiment 2

[0024] Put 5 pieces of yak hides that have been soaked in water, degreased and combed into the drum, add water with a liquid ratio of 8 at 25°C, and rotate for 30 minutes; then add sodium chloride to make the concentration 10g / L, and rotate for 30 minutes; Then add formic acid in 3 times in equal parts, with an interval of 1 hour between each time, so that the final concentration is 3g / L, during which the drum rotates; after that, the drum rotates at a speed of 4r / min, and stops for 50min every 10min until the acid expands. The total time reaches 24 hours; the yak skin is taken out from the drum, combed and finished according to the conventional yak decorative fur processing technology, and then the skin is sliced and the thickness of the skin after the skin is controlled to be 80-85% of the initial thickness of the skin; Afterwards, conventional follow-up processing can be carried out.

Embodiment 3

[0026] Put 5 pieces of yak hides that have been soaked in water, degreased and combed into the drum, add water with a liquid ratio of 9 at 25°C, and rotate for 30 minutes; then add potassium chloride to make the concentration 7.5g / L, and rotate for 30 minutes ; Then add formic acid in 5 times in equal parts, with an interval of 1 hour between each time, so that the final concentration is 5g / L, during which the drum rotates; after that, the drum rotates at a speed of 3r / min, and stops for 50min every 10min until the acid The total expansion time reaches 36 hours; the yak skin is taken out from the drum, combed and finished according to the conventional yak decorative fur processing technology, and then the skin is sliced and the thickness of the skin plate is controlled to be 80-85% of the initial thickness of the skin plate ; Thereafter, conventional follow-up processing can be carried out.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com