Hanging basket levelling control system

A control system and leveling technology, applied in the direction of electric controllers, control using feedback, controllers with specific characteristics, etc. issues such as

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

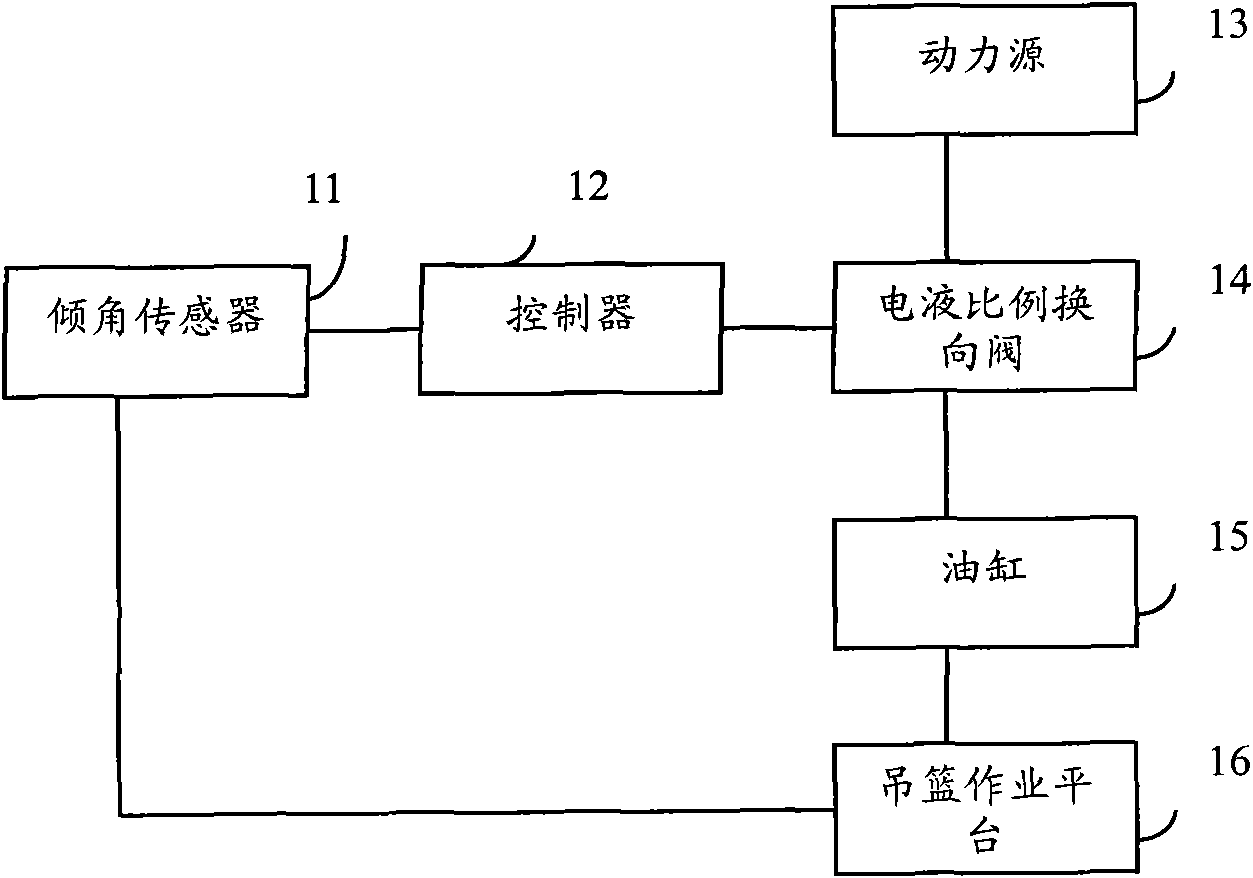

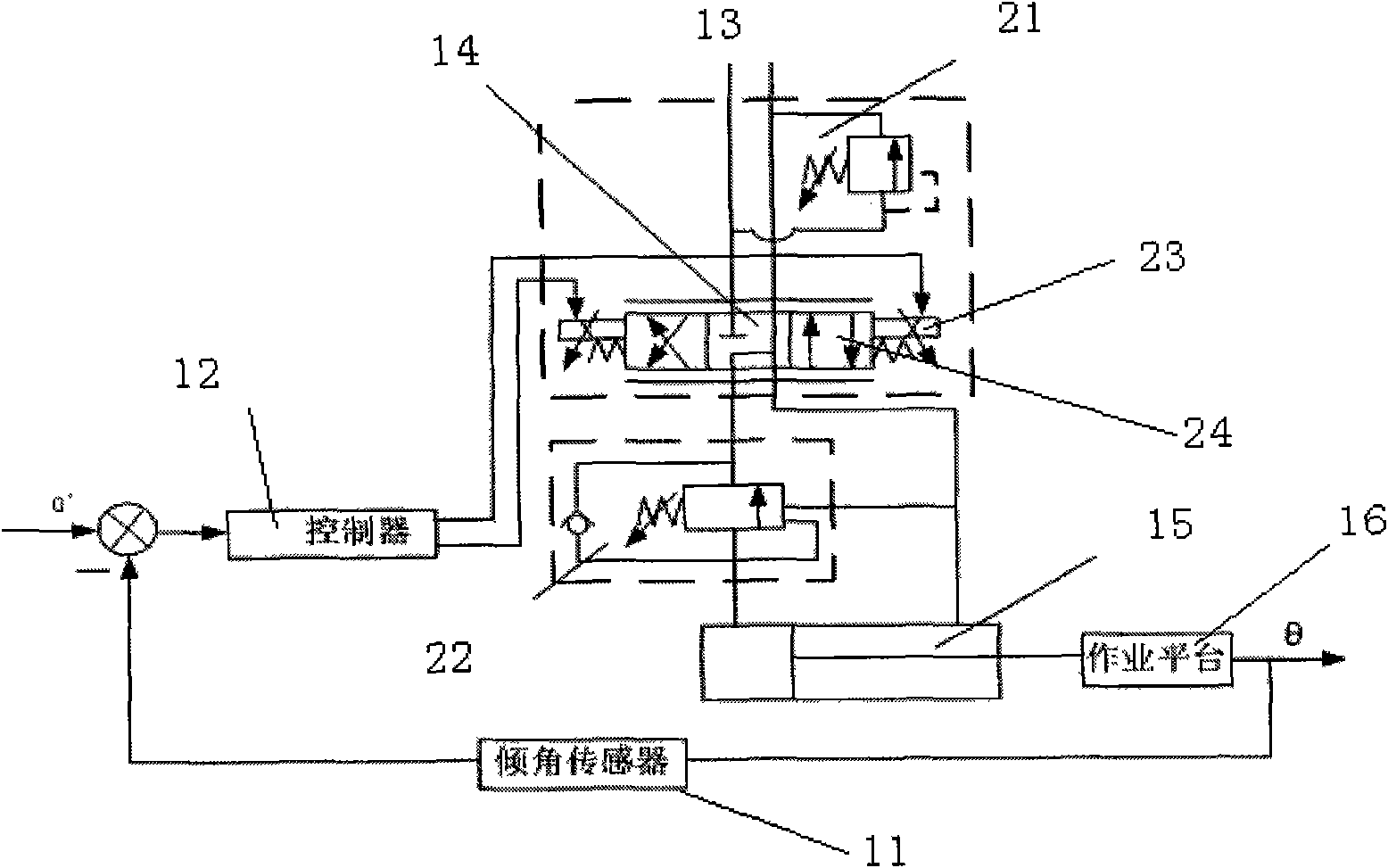

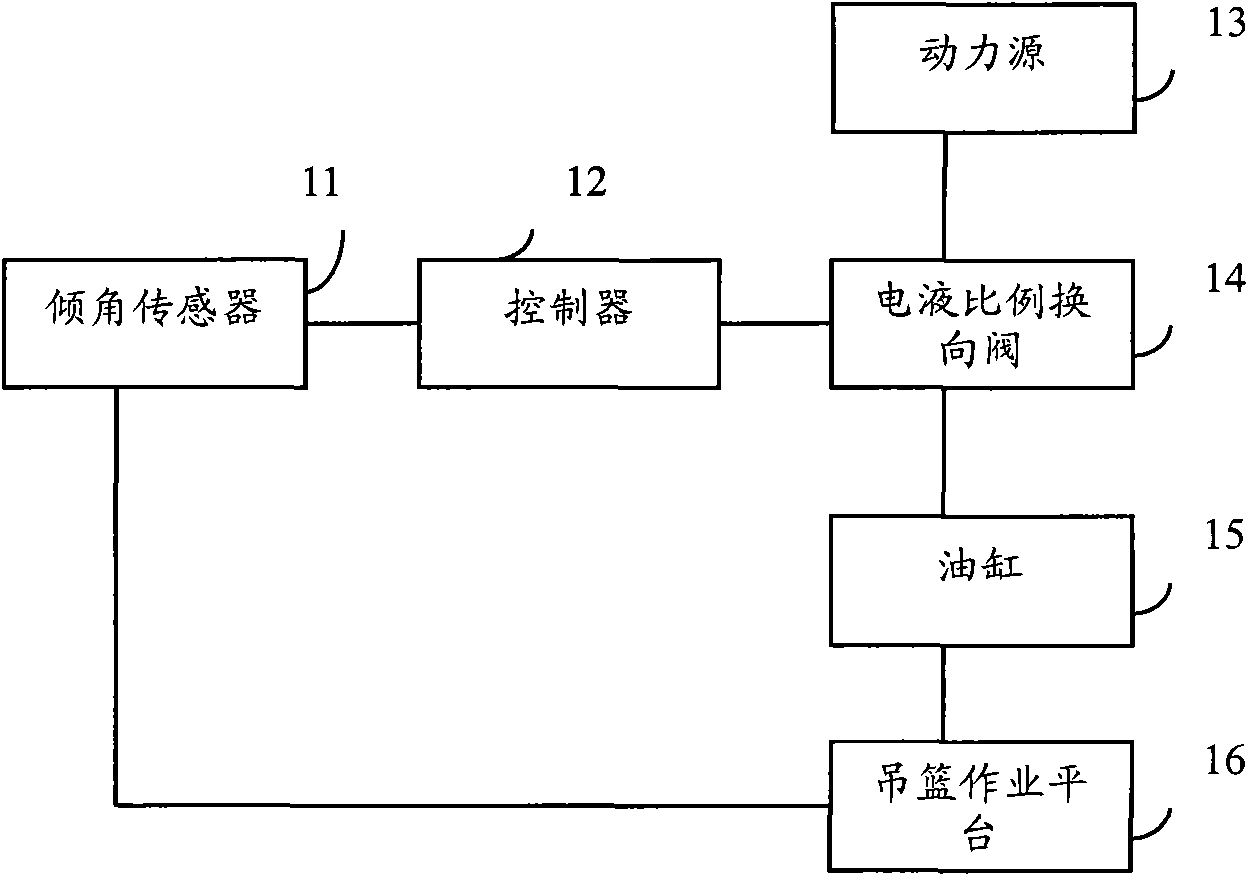

[0015] refer to figure 1 ,Such as figure 1 As shown, the inclination sensor 11 detects the inclination angle of the working platform of the hanging basket, wherein the inclination sensor can be three kinds of inclination sensors of the "solid pendulum" type, the "liquid pendulum" type and the "gas pendulum" type; If the angle is greater than the angle set by the forward tilt sensor, the tilt sensor will generate a corresponding current signal according to the actually detected deviation angle and send it to the controller 12, wherein the deviation angle is proportional to the current signal produced by the sensor; the controller 12 uses The PID control algorithm performs calculations, outputs PWM (pulse width modulation control) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com