Device for evaluating sand-blocking performance of sieve with sieve tube

An evaluation device and screen technology, applied in the field of analog measurement, can solve the problems of oil and gas wells such as irreversible damage, gas flow reduction, well wall collapse, etc., and achieve the effect of improving sand control efficiency and working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

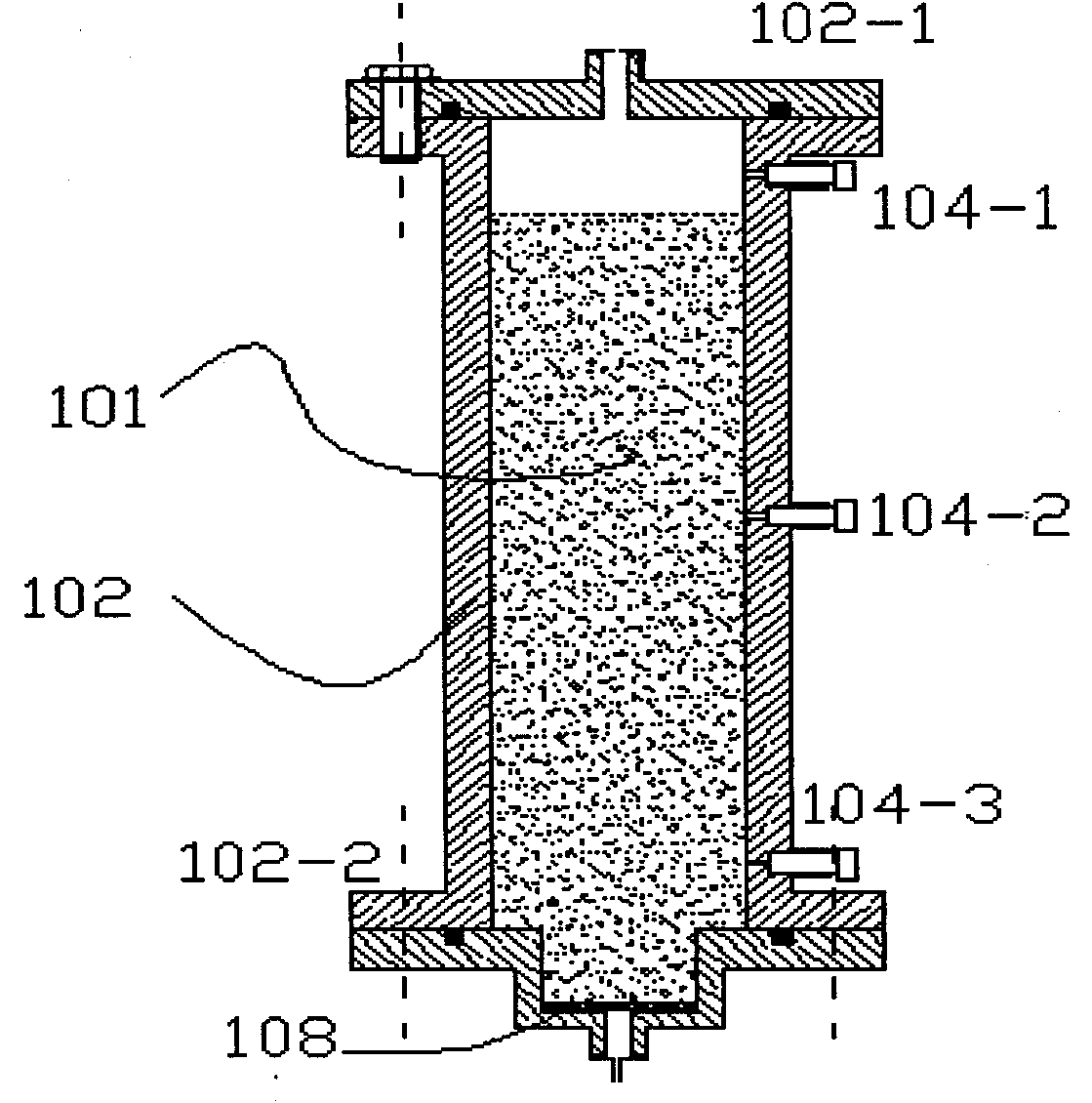

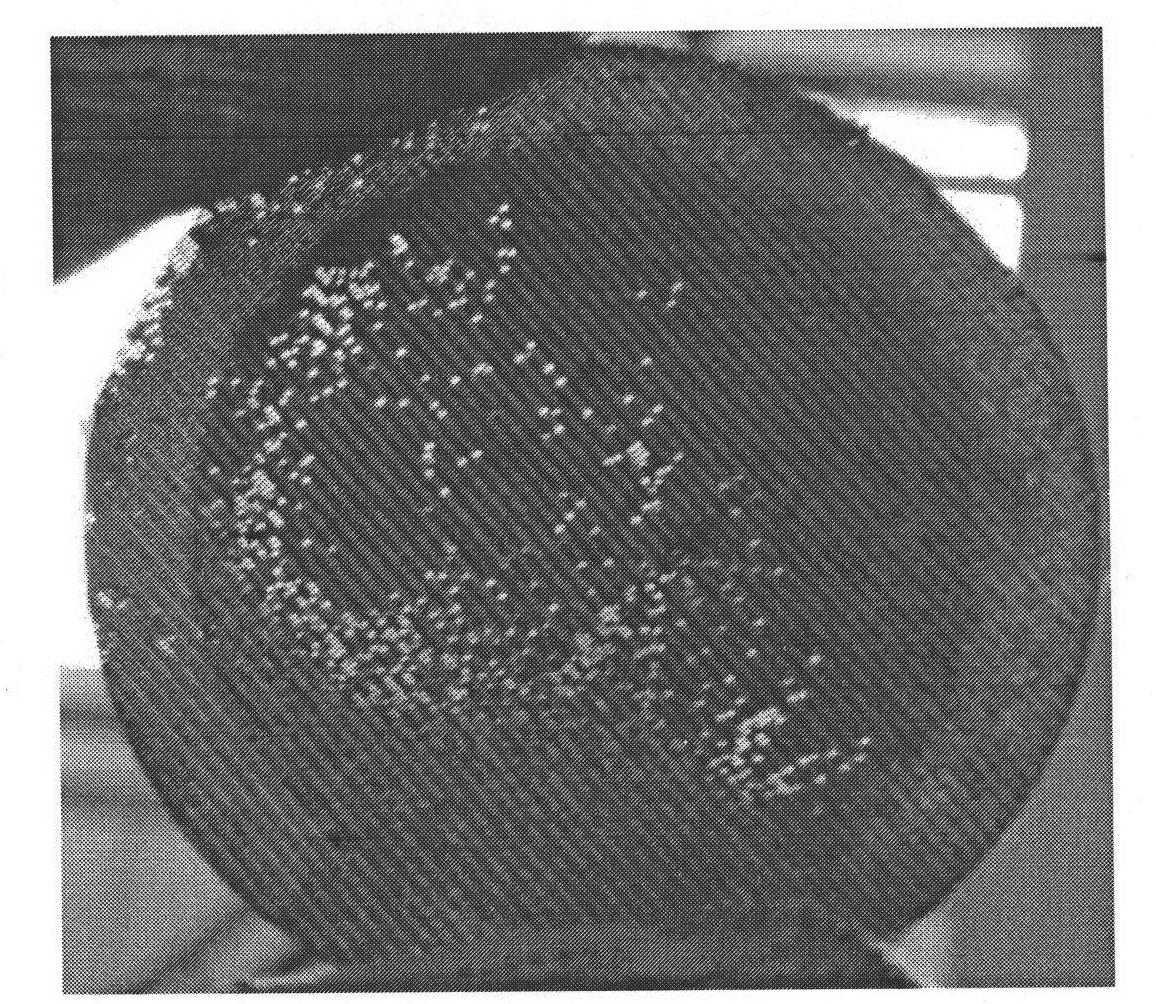

[0022] The simulated stratum of simulated borehole surrounding rock stratum was prepared by mixing the finished sand and bentonite. The shale content of the simulated stratum was 12.5%, the separation coefficient was 5, and the median sand grain size of the simulated stratum was 0.15mm. The sand control screen screen mesh combination to be evaluated is 80μm+120μm. The inventive device is assembled, and the hydraulic power unit provides a simulated differential pressure of 3Mpa to the cylinder. The pressures at the upper, middle and lower positions in the cylinder body 102 are 3Mpa, 2.25MPa, and 1.5MPa respectively; the fluid flow through the sand control screen to be evaluated is 0.05L / s, and the simulated formation sand output is 25.721g (collected time 95s). image 3 It shows that the screen of the sand control screen is generally clogged, and the data shows that the screen of the sand control screen is well compatible with the working environment.

Embodiment 2

[0024] The simulated stratum of simulated wellbore surrounding rock stratum was prepared by mixing finished sand and bentonite. The shale content of the simulated stratum was 5%, the separation coefficient was 8, and the median sand grain size of the simulated stratum was 0.20mm. The sand control screen screen mesh combination to be evaluated is 80μm+120μm. The inventive device is assembled, and the hydraulic power unit provides a simulated differential pressure of 5Mpa to the cylinder. The pressures at the upper, middle and lower positions in the cylinder body 102 are 5Mpa, 3.5MPa, and 1.3MPa respectively; the fluid flow through the sand control screen to be evaluated is 0.04L / s, and the simulated formation sand output is 45.31g (collected time 95s). Figure 4 It shows that the screen of the sand control screen is seriously blocked, and the data shows that the screen of the sand control screen is not compatible with the working environment.

Embodiment 3

[0026] The simulated stratum of simulated wellbore surrounding rock stratum was prepared by mixing finished sand and bentonite. The shale content of the simulated stratum was 5%, the separation coefficient was 8, and the median sand grain size of the simulated stratum was 0.20mm. The combination of sand control screen screen mesh to be evaluated is 90μm+120μm. The inventive device is assembled, and the hydraulic power unit provides a simulated differential pressure of 5Mpa to the cylinder. The pressures at the upper, middle and lower positions in the cylinder body 102 are 5Mpa, 3.8MPa, and 1.7MPa respectively; the fluid flow through the sand control screen to be evaluated is 0.06L / s, and the simulated formation sand output is 23.37g (collected time 95s). The screen of the sand control screen is generally clogged, and the data shows that the screen of the sand control screen is well compatible with the working environment.

[0027] By using the evaluation method of the presen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com