Split measurement method and device for spatial position in three-dimensional field

A technology of spatial position and measurement method, applied in the direction of measurement device, optical device, instrument, etc., can solve the problems of linear error, high cost, complex optical path, etc., and achieve the effect of large measurement flexibility, simple structure and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

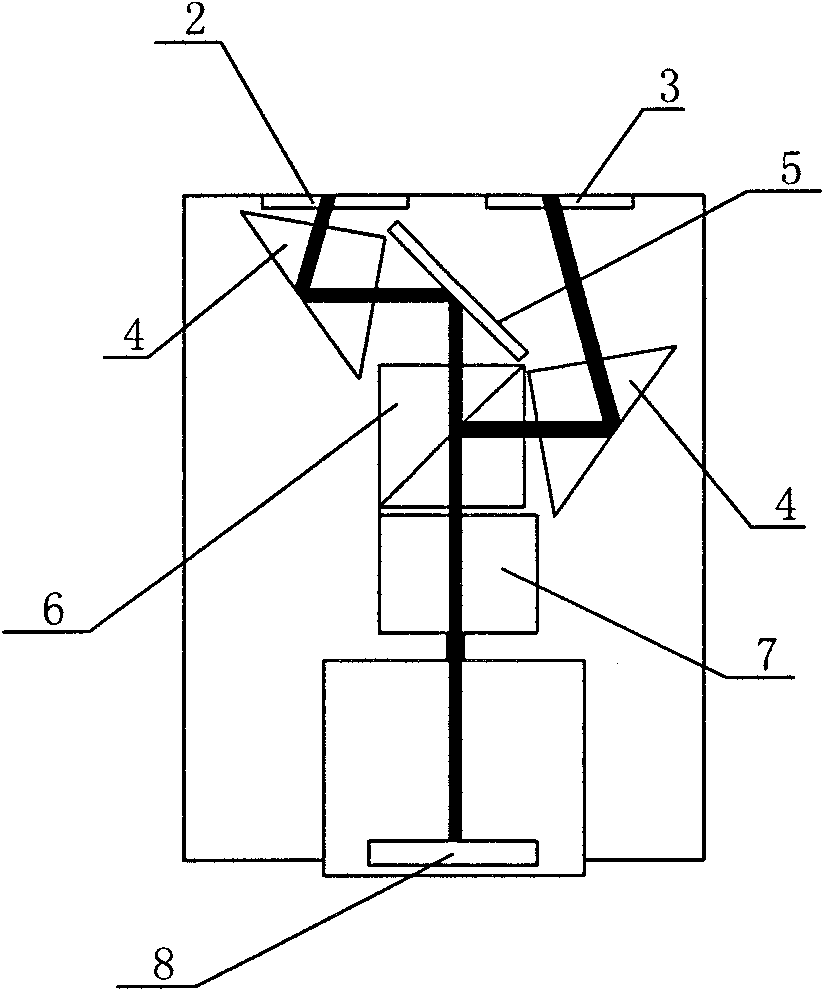

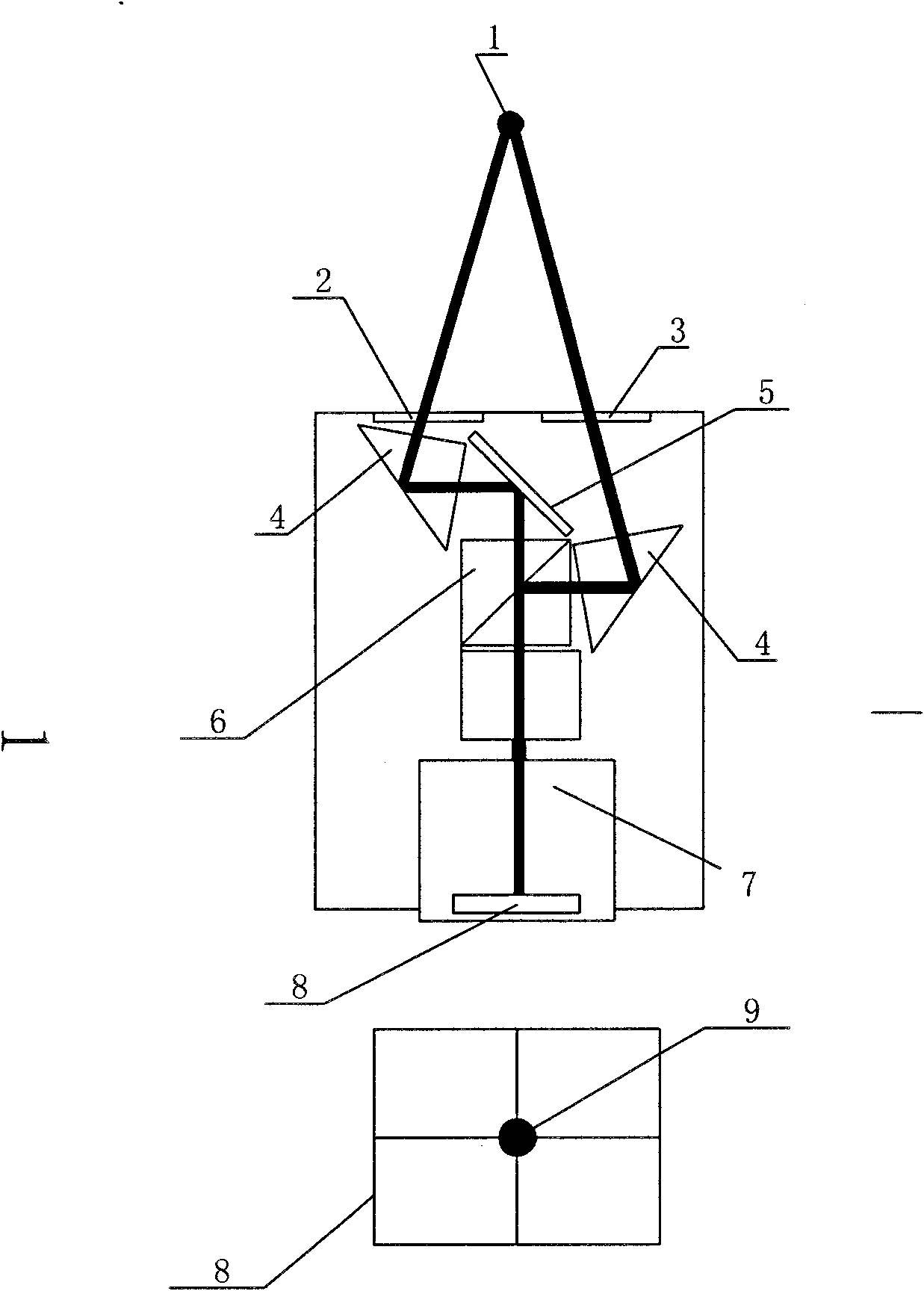

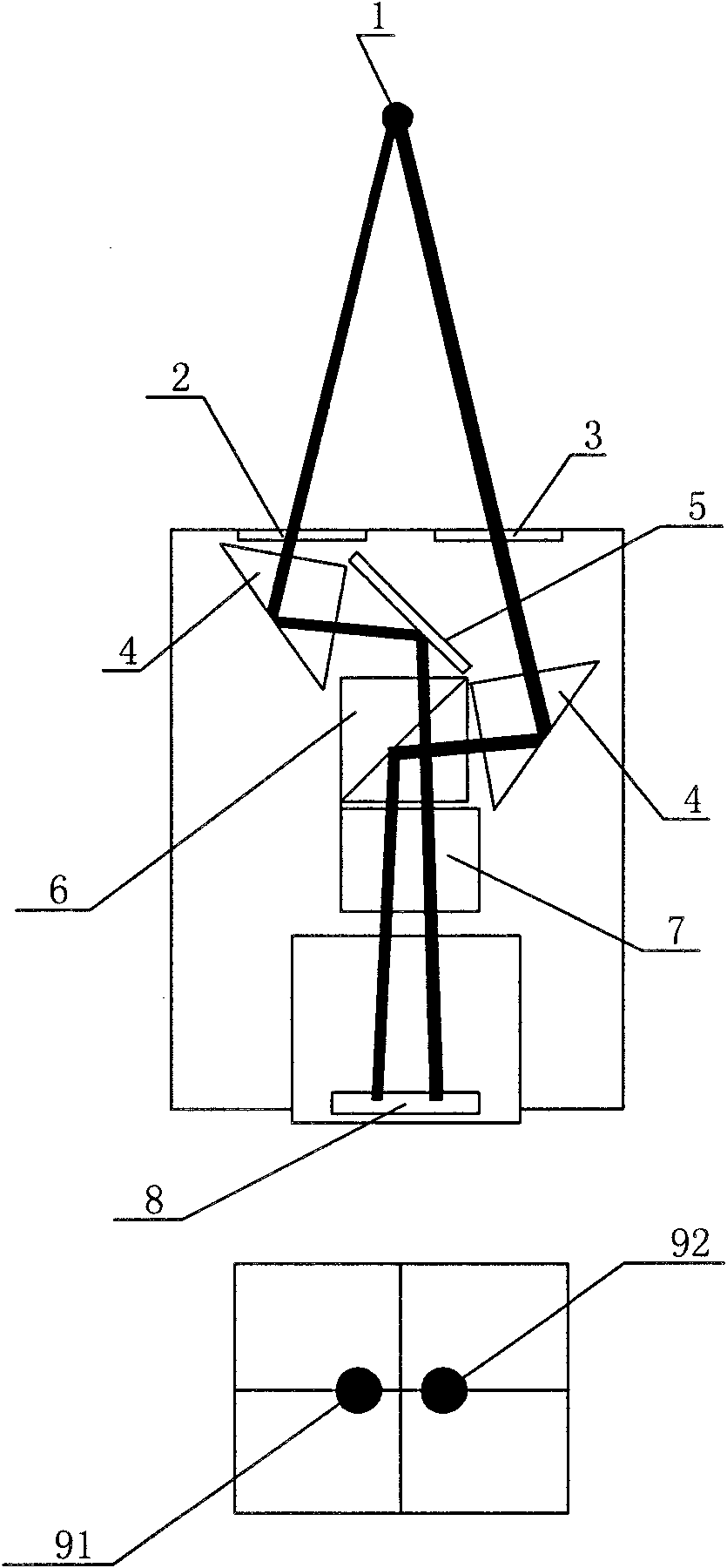

[0019] The specific embodiment: the present invention will be further described below in conjunction with accompanying drawing:

[0020] Firstly, the labels in each drawing are introduced: 1. Luminous object point; 2. Red filter; 3. Green filter; 4. Right-angle prism; 5. Plane mirror; 6. Cube prism; 7. CCD camera; 8. Negative film; 9. Pixels; 91. Green pixels; 92. Red pixels.

[0021] The invention is a measuring method and device for measuring the spatial position of an object in a three-dimensional field by using photoelectric technology. The device comprises two different color filters (referring to red filter 2 and green filter 3 here); a flat mirror, a rectangular prism, a cube prism and a CCD camera. The luminescent object points are imaged on the CCD camera through the red filter and the green filter respectively, and through the rectangular prism, the plane glass mirror and the cubic prism. Due to the different spatial positions of the luminous object points in the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com