Method for forecasting Mooney viscosity in rubber mixing process

A Mooney viscosity and rubber mixing technology, applied in the field of soft measurement, can solve the problems of inability to integrate nonlinear and time-varying information in time, stay, and inability to meet real-time online control in industrial sites.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

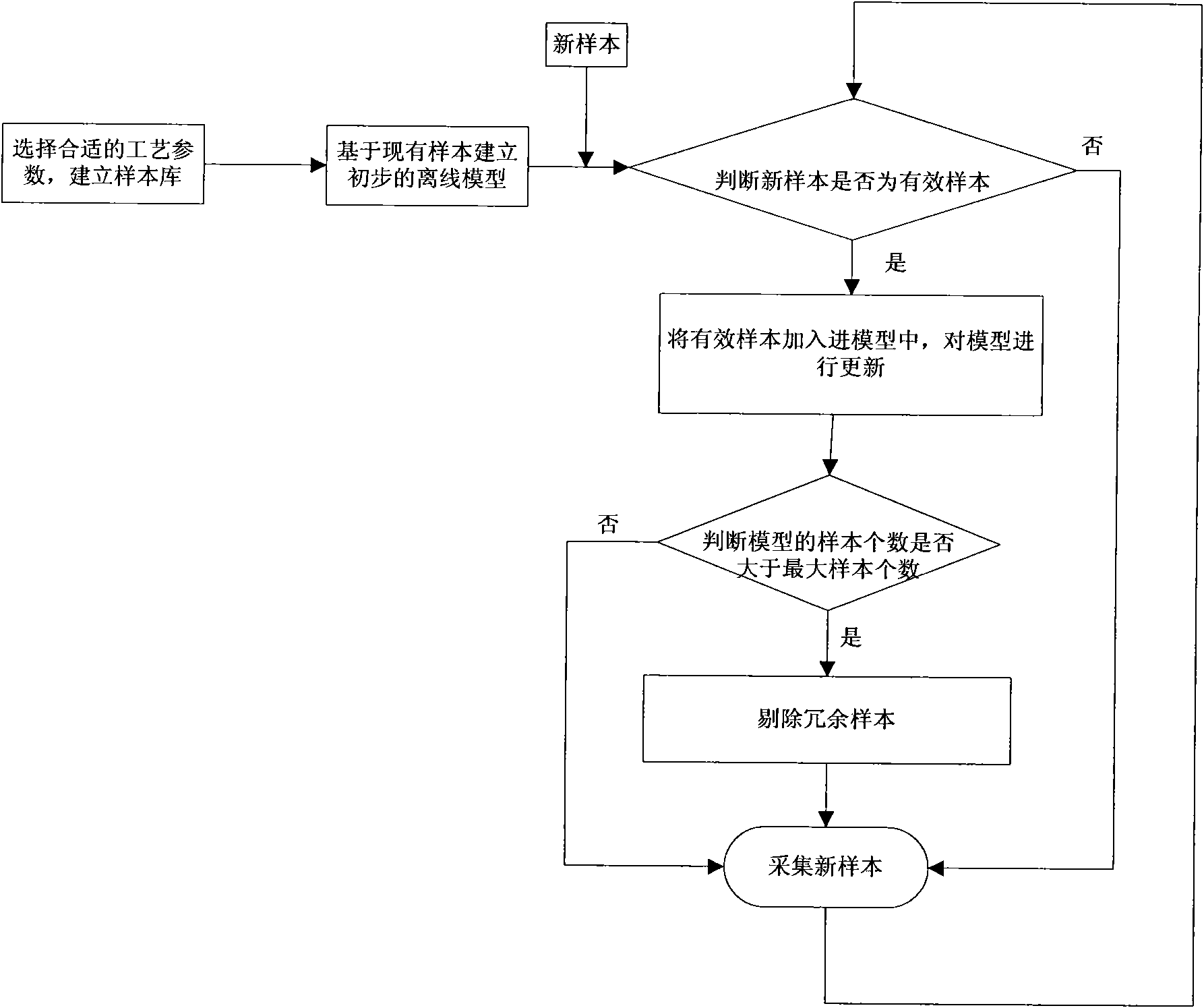

[0054] Such as figure 1 Shown, a kind of prediction method of Mooney viscosity in rubber mixing process comprises the following steps:

[0055] (1) Select appropriate process parameters and establish a sample library;

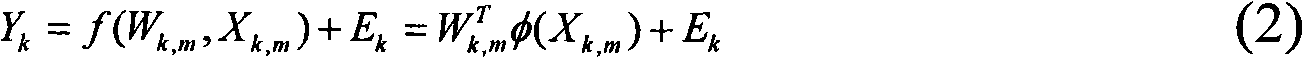

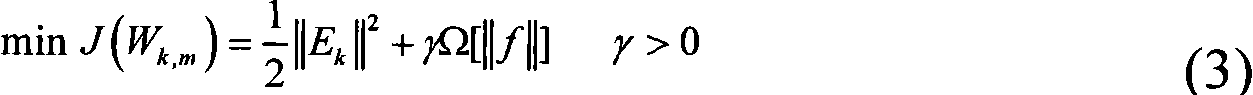

[0056] Since the rubber mixing process involves a wide variety of formulations, different types of internal mixers and mixing processes, it is impossible to establish a single fixed model. It is only feasible to establish different models according to the characteristics of the process to predict the Mooney viscosity. Therefore, this specific embodiment does not consider relatively fixed factors in the rubber mixing process (for example: internal mixer model, master batch / final mixing process, etc.), and the update of the online model is only for possible changes in the rubber mixing process the elements of. During the rubber mixing process, a large amount of industrial field data is generated, such as formula, mixing time, temperature, energy consumption, pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com