Servo Drives for Bidirectional Actuators

A servo drive device, actuator technology, applied in the direction of valve device, valve operation/release device, charging system, etc., can solve the problem of short actuation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

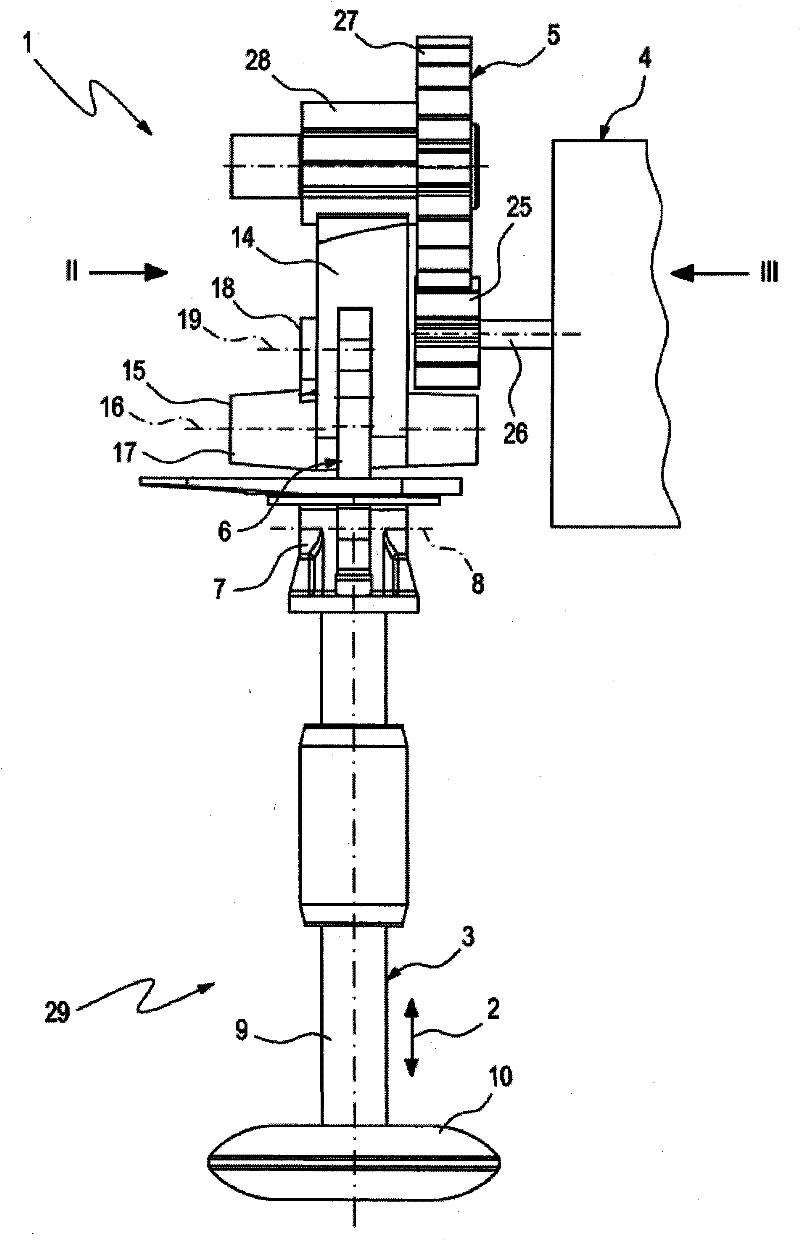

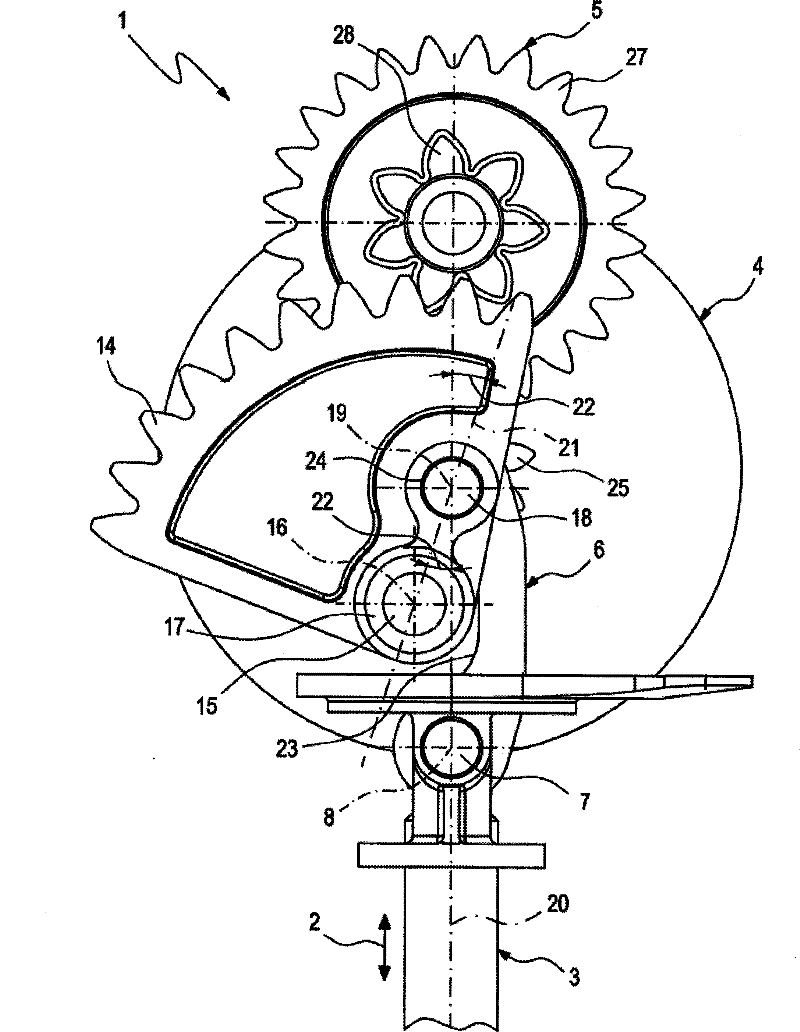

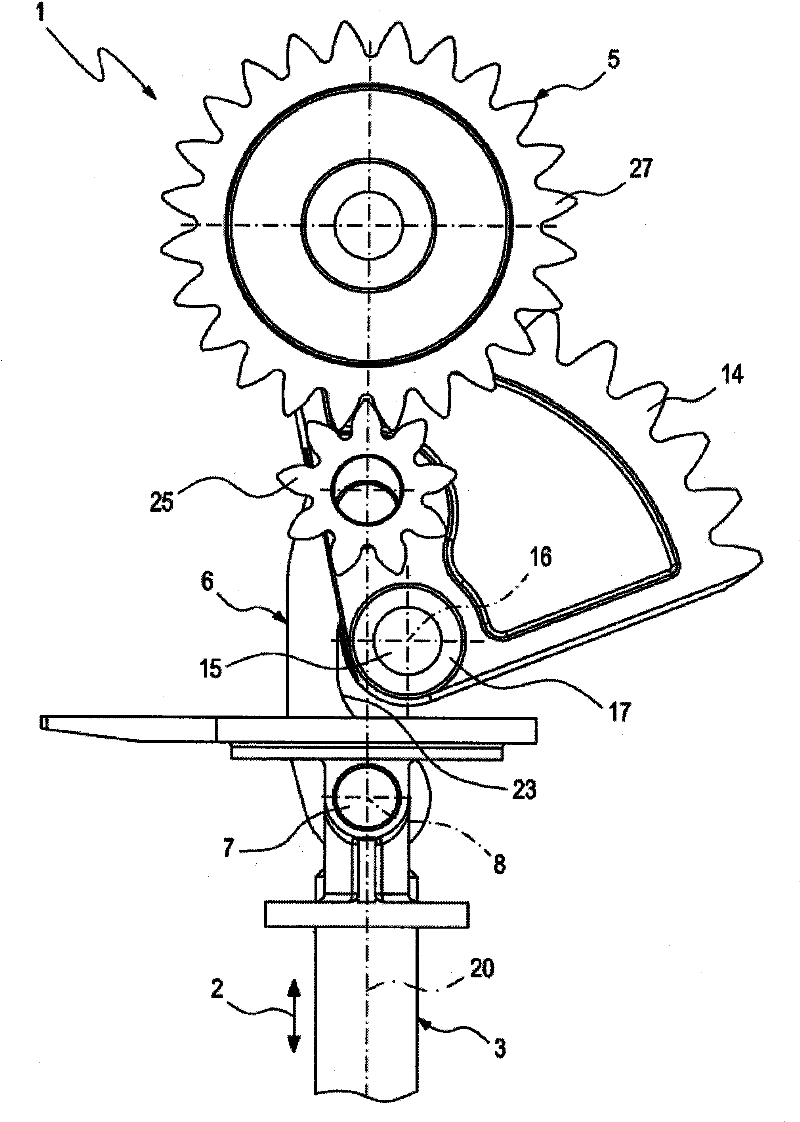

[0017] according to Figure 1-4 , A servo drive device 1 with which the actuator 3 can be driven, which can be adjusted in both directions according to the bidirectional arrow 2. The device includes a motor 4, a gear device 5 and a crank connecting rod 6. The crankshaft connecting rod 6 can be connected to the actuator 3 through the first crank connecting rod bearing 7 in an engaging manner. Here, the corresponding first crank connecting rod bearing shaft is marked as 8. In the assembled state shown in the figure, the crank connecting rod 6 through its first crank connecting rod bearing 7 is connected to the actuator 3 in an engaging manner. in Figure 1-3 In the illustrated embodiment, the actuator 3 is a valve assembly 9 carrying a valve body 10. according to Figure 4 In the embodiment shown in the actuator 3, the actuator 3 is used to drive a reciprocating lever (return lever) 11, which in turn is connected to the valve body 12 in a rotationally fixed manner, and is rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com