Actuating drive for bidirectional actuator

A technology of servo drive device and actuator, applied in valve device, valve operation/release device, charging system, etc., can solve problems such as short actuation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

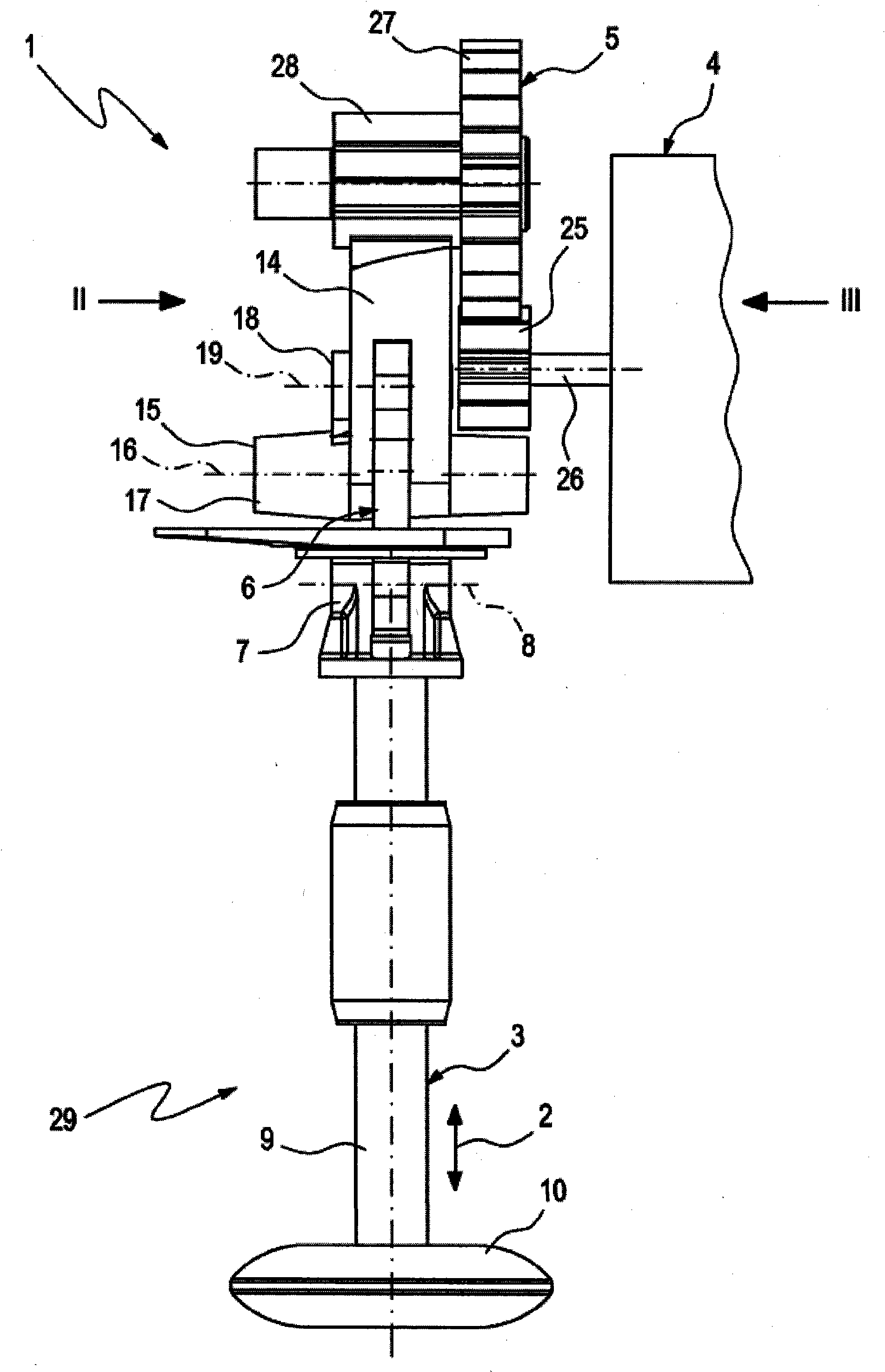

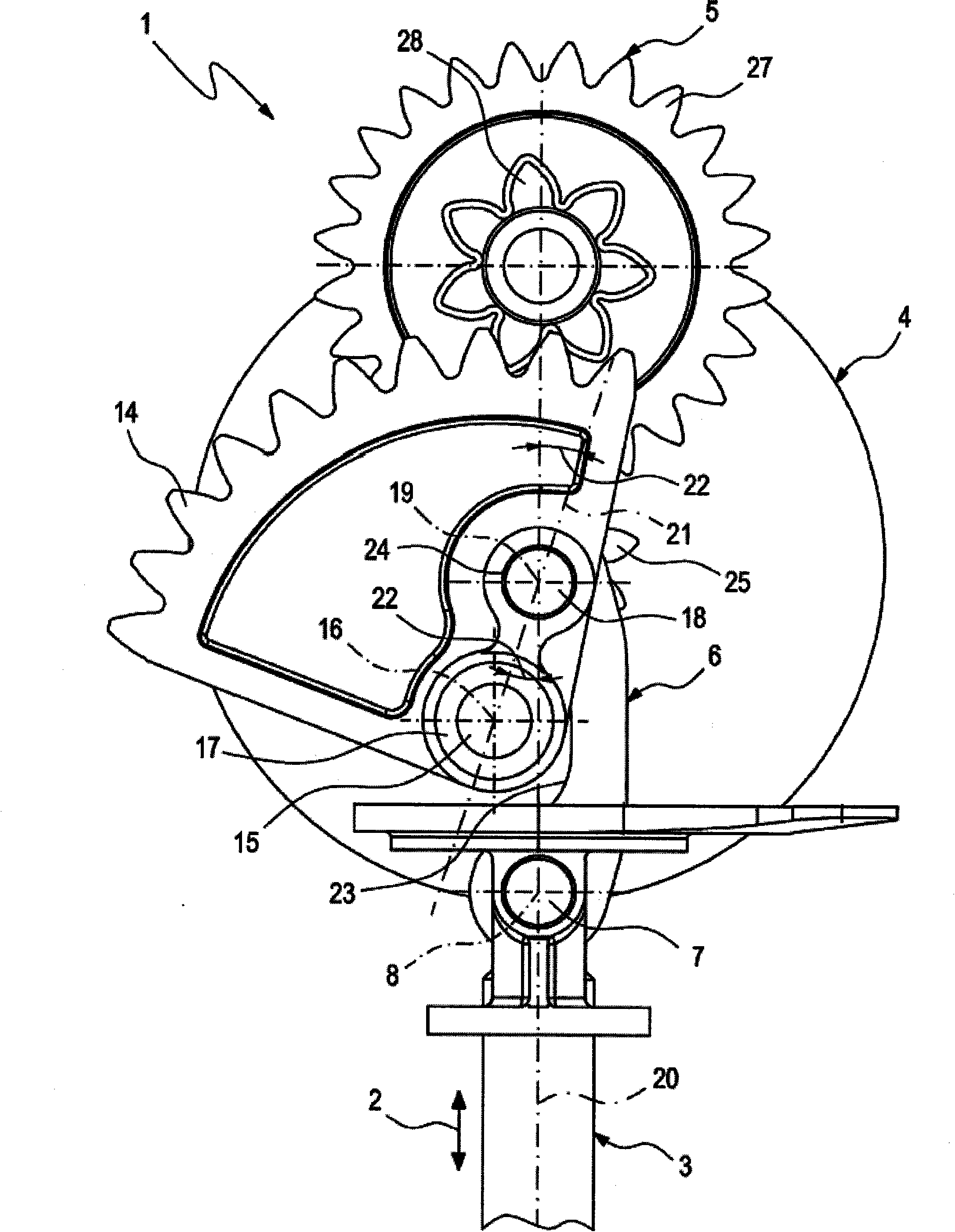

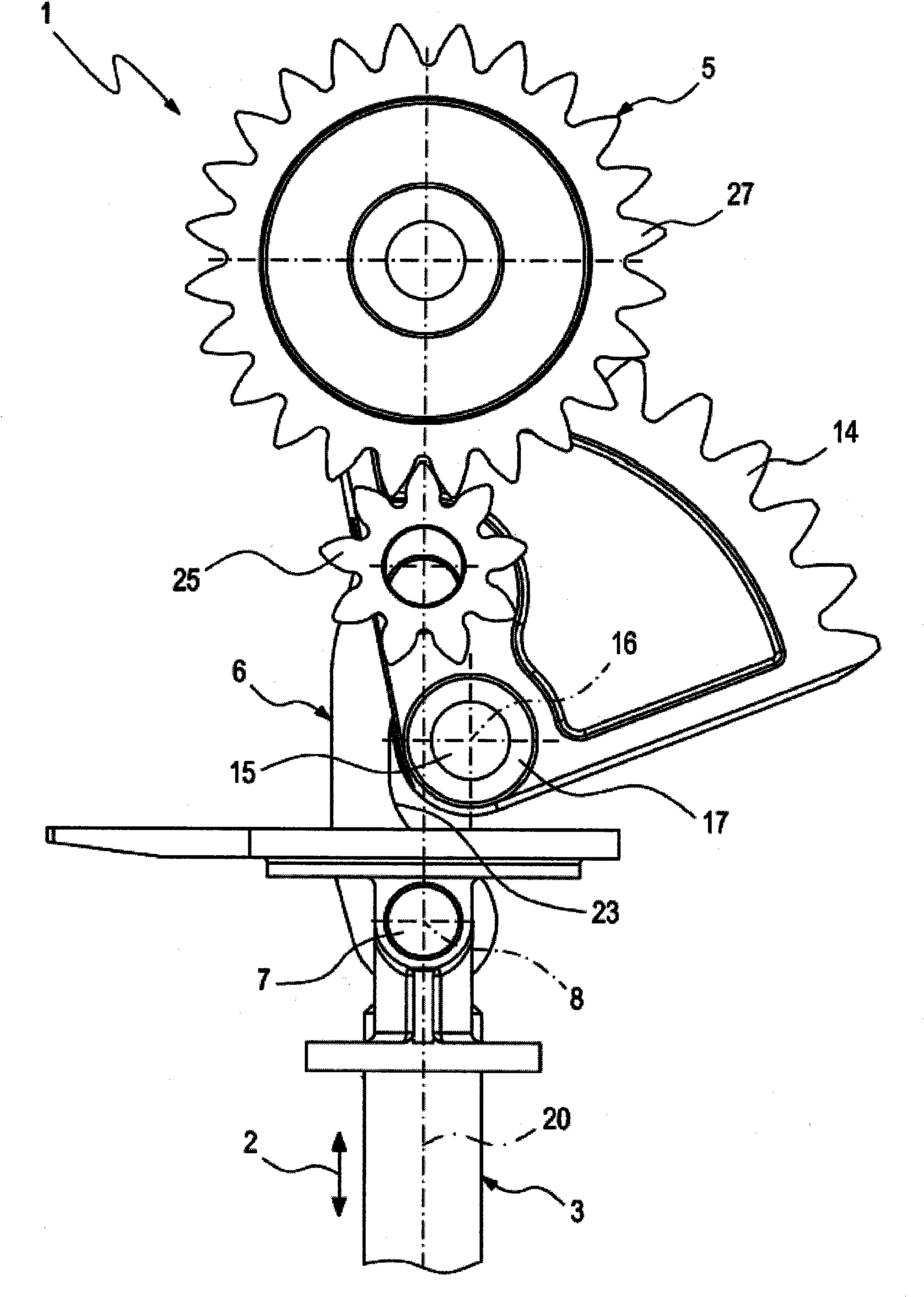

[0017] according to Figure 1-4 , a servo drive device 1, with which the actuator 3 can be driven, the actuator can be adjusted in both directions according to the double arrow 2, the device includes a motor 4, a gear device 5 and a crank connecting rod 6. The crankshaft connecting rod 6 can be connected to the actuator 3 in a meshing manner via a first crankshaft connecting rod bearing 7 . Here, the corresponding first crank-rod bearing shaft is referenced 8 . In the assembled state shown, the crank rod 6 is engaged with the actuator 3 via its first crank rod bearing 7 . exist Figure 1-3 In the embodiment shown, the actuator 3 is a valve assembly 9 carrying a valve body 10 . according to Figure 4 In the embodiment shown in the figure, the actuator 3 is used to drive the reciprocating lever (return lever) 11, which in turn is connected to the valve body 12 in a rotationally fixed manner, itself rotatably mounted about the axis of the rotating shaft 13, and The valve bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com