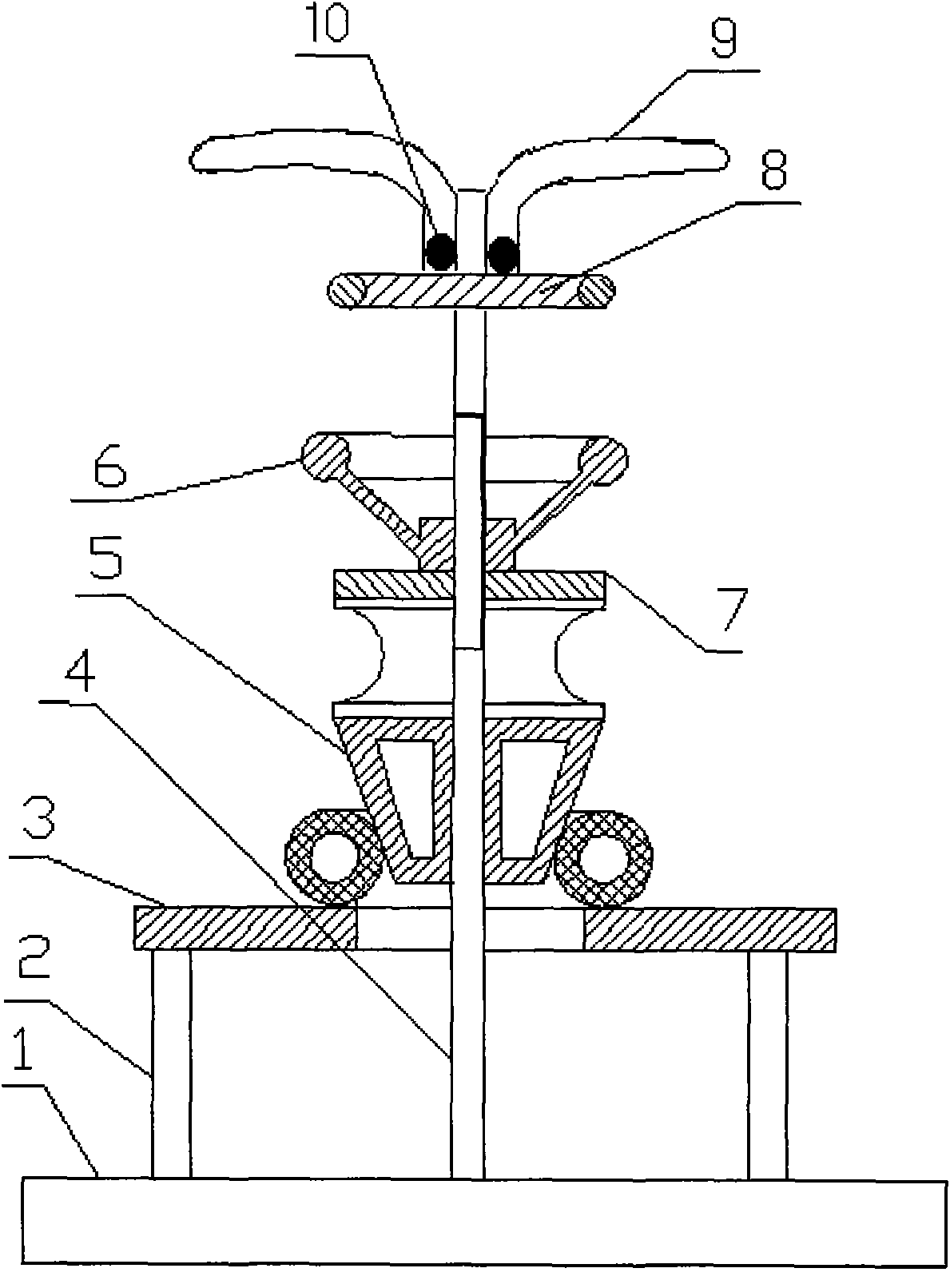

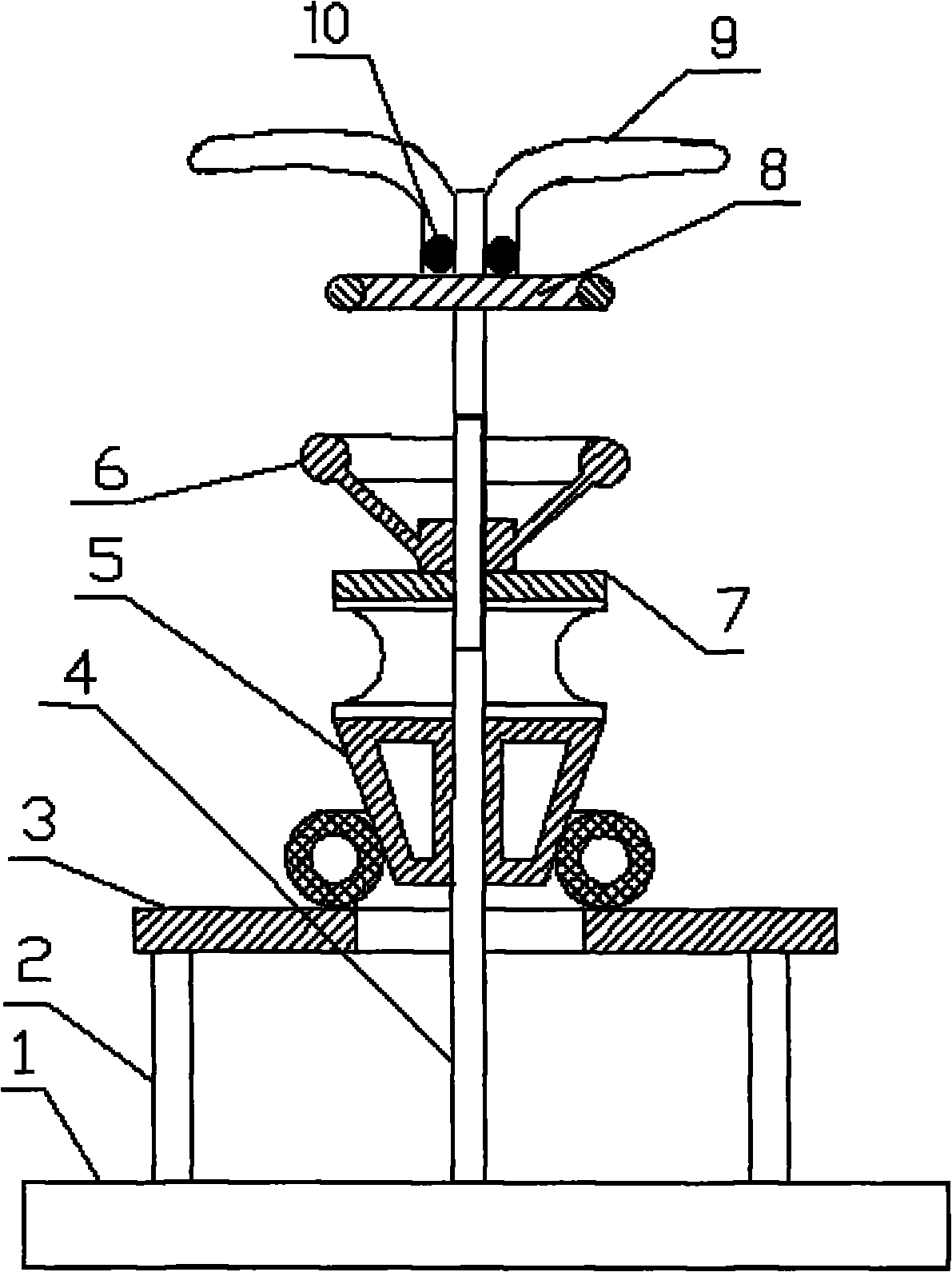

Novel hub and tyre assembling mechanism

A tire assembly and wheel hub technology, which is applied in the directions of wheel assembly equipment, wheels, transportation and packaging, can solve the problems of expensive tool manufacturing and complex structure, and achieves a solution to complex structure and tool manufacturing. simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Fix an appropriate number of uprights (2) with the same height on the bottom plate. Install a receiving plate (4) at the upper end of the upright (2). The center of the receiving plate has a hole c. The diameter of the hole c is slightly larger than the outer circle of the hub. The diameter of the drawing rod (4) is fixedly installed on the upper plane of the base (1). When installing, ensure that the axis of the drawing rod (4) is basically concentric with the center line of the hole c. When it is not working, open the hole in the middle The guide body is installed on the thread of the drawing rod (4) to prevent accidental loss of parts. Remove the large handwheel (6) when working, and place the tire a filled with a certain pressure on the receiving plate (3) in the middle of the drawing rod (4), and at the same time install the guide body (5) on the drawing rod (4) in turn The hub b, the large handwheel (6), the small handwheel (8), and the brake lever (9) are fixed wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com