Novel straw fiber ridged plate and manufacturing method thereof

A technology for straw fibers and plates, which is applied in the pretreatment of molding materials, manufacturing tools, flat products, etc., can solve the problems of not achieving environmental protection performance, incomplete sterilization performance, and weak water resistance, and can solve the problems of straw The effect of serious waste of resources, light weight and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

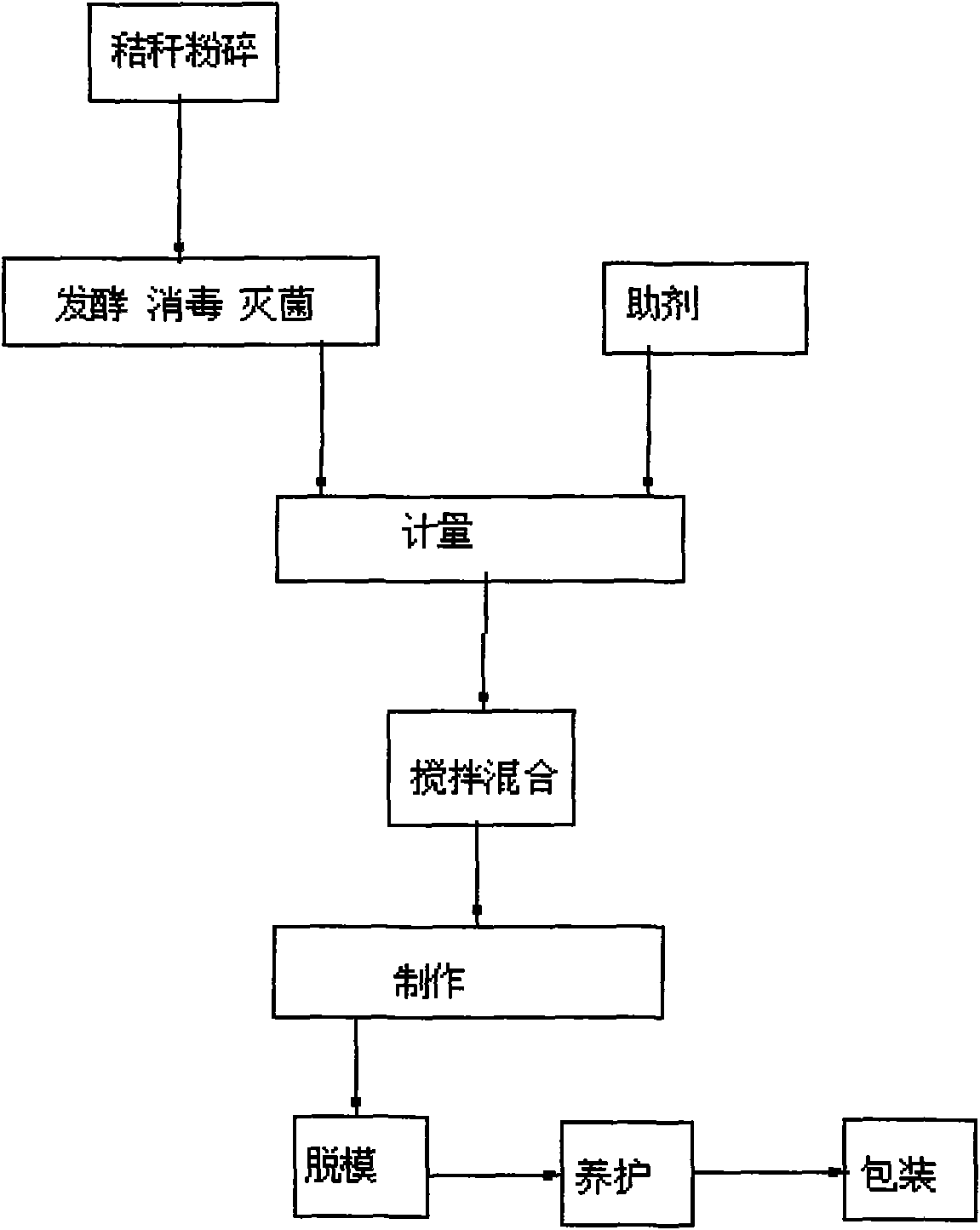

Method used

Image

Examples

Embodiment 1

[0010] Embodiment 1: crop straw powder 46%, slag powder 13%, talcum powder 5%, magnesium oxide 35%, additive (1) 0.2%, additive (2) 0.8%, described percentage is weight percentage.

[0011] Combine all the above materials together, put them into a mixer and stir them for 120-150 minutes, take them out after mixing fully, and put them into the temperature-controlled control pool. It is required to control the temperature of the temperature-controlled control pool at 20°C-35°C Between ℃, control the temperature of the softened substance to be between 40% and 50%, the time to control the temperature of the softened substance is 120 minutes, and then add 40% to 50% of water (the best is 45%) to achieve natural Fermentation and sterilization treatment, after 48 hours of natural fermentation, take the mixed substance out of the control tank, put it into the program-controlled mold and pressurize, it is required to start controlling the temperature of the program-controlled mold to be...

Embodiment 2

[0013] Embodiment 2: crop straw powder 54%, slag powder 10%, talcum powder 10%, magnesium oxide 25%, additive (1) 0.6%, additive (2) 0.4%, described percentage is weight percentage.

[0014] Combine all the above materials together, put them into a mixer and stir them for 120-150 minutes, take them out after mixing fully, and put them into the temperature-controlled control pool. It is required to control the temperature of the temperature-controlled control pool at 20°C-35°C Between ℃, control the temperature of the softened substance to be between 40% and 50%, the time to control the temperature of the softened substance is 120 minutes, and then add 40% to 50% of water (the best is 45%) to achieve natural Fermentation and sterilization treatment, after 48 hours of natural fermentation, take the mixed substance out of the control tank, put it into the program-controlled mold and pressurize, it is required to start controlling the temperature of the program-controlled mold to b...

Embodiment 3

[0016] Example 3: crop straw powder 50%, slag powder 12%, talcum powder 7%, magnesium oxide 30%, additive (1) 0.4%, additive (2) 0.6%, and the percentages described are percentages by weight.

[0017] Combine all the above materials together, put them into a mixer and stir them for 120-150 minutes, take them out after mixing fully, and put them into the temperature-controlled control pool. It is required to control the temperature of the temperature-controlled control pool at 20°C-35°C Between ℃, control the temperature of the softened substance to be between 40% and 50%, the time to control the temperature of the softened substance is 120 minutes, and then add 40% to 50% of water (the best is 45%) to achieve natural Fermentation and sterilization treatment, after 48 hours of natural fermentation, take the mixed substance out of the control tank, put it into the program-controlled mold and pressurize, it is required to start controlling the temperature of the program-controlled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com