Drive unit

A driving unit and stopper technology, applied in the direction of electrical components, current collectors, rotary current collectors, etc., can solve problems such as large overhead, and achieve the effect of cheap manufacturing and simplifying the push-in process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

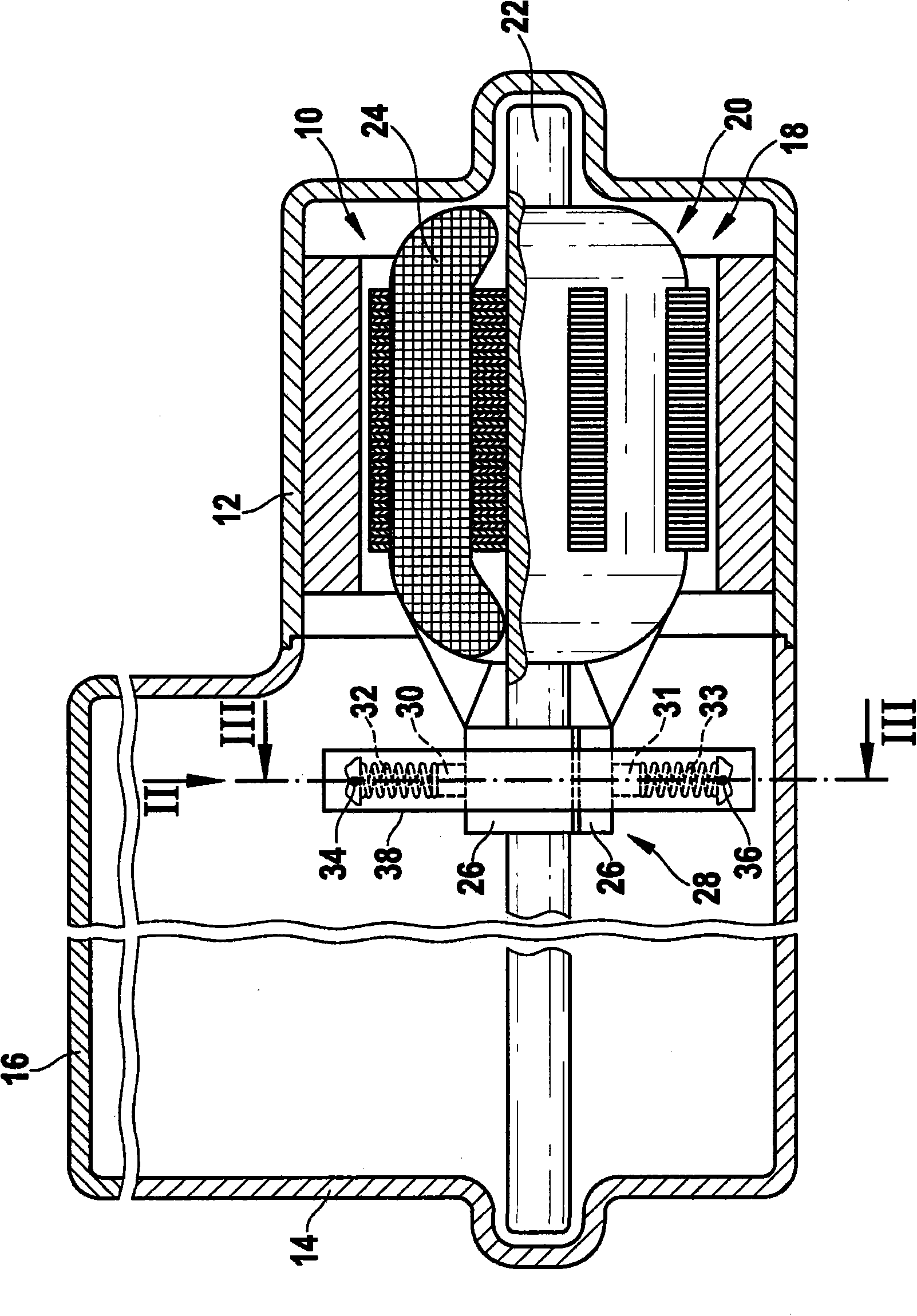

[0011] exist figure 1 10 denotes a schematically illustrated DC motor of the drive unit, which is arranged in a motor housing 12 to which a transmission housing 14 is flanged. The gear housing is closed by a gear cover 16 which, in the removed state, allows access for assembly purposes.

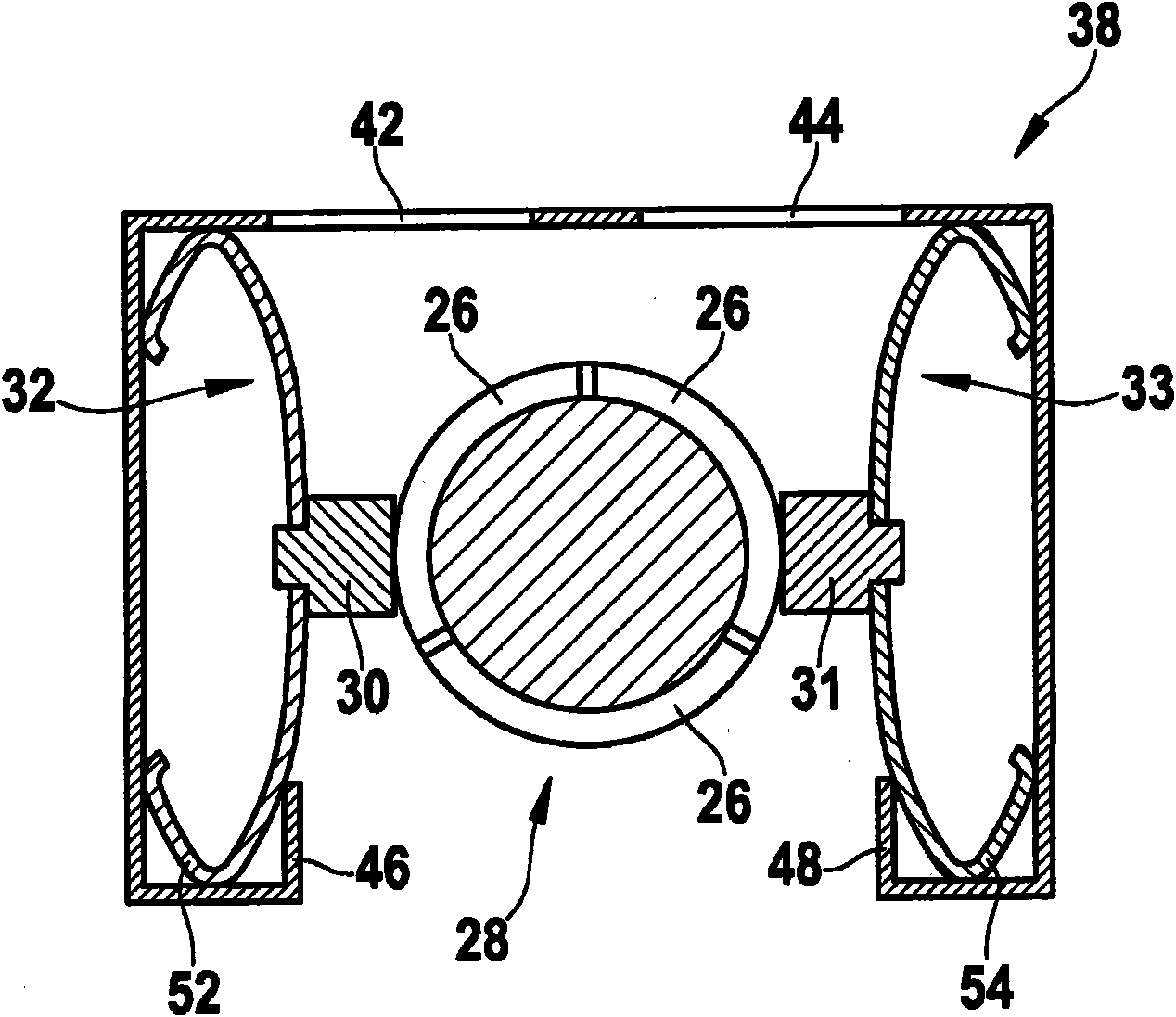

[0012] The DC motor 10 is designed as a commutator motor with a stator 18 and a rotor 20 whose shaft 22 extends as a drive shaft into the transmission housing 14 and is equipped with transmission components not shown. The rotor winding is indicated with 24 and is electrically conductively connected to laminations 26 of a commutator 28 which is likewise fastened on shaft 22 . Brushes 30 and 31 slide on the circumference of the commutator, said brushes being pressed radially against commutator 28 by symbolic brush springs 32 and 33 . The joints of the brush springs 32 and 33 are connected to the positive pole 34 and the negative pole 36 of the DC power supply.

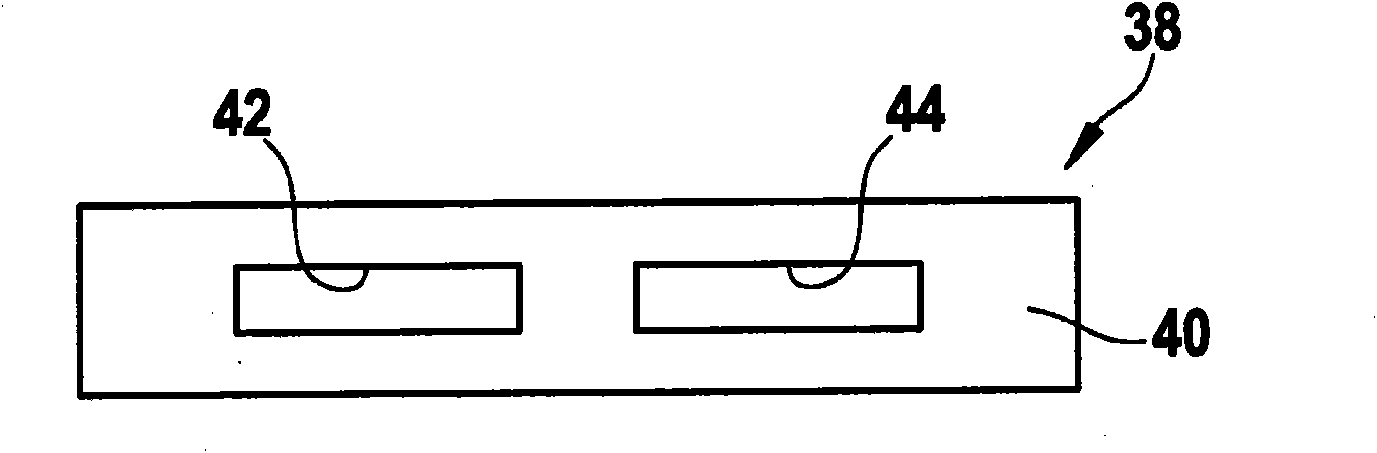

[0013] In the exemplary embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com