Disc brake

A technology of disc brakes and pads, applied in the direction of brake types, axial brakes, brake components, etc., can solve problems such as easy lowering, unstable shape, easy permanent deformation, etc., to reduce drag and vibration, prevent Sloshing, achieving a stabilizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

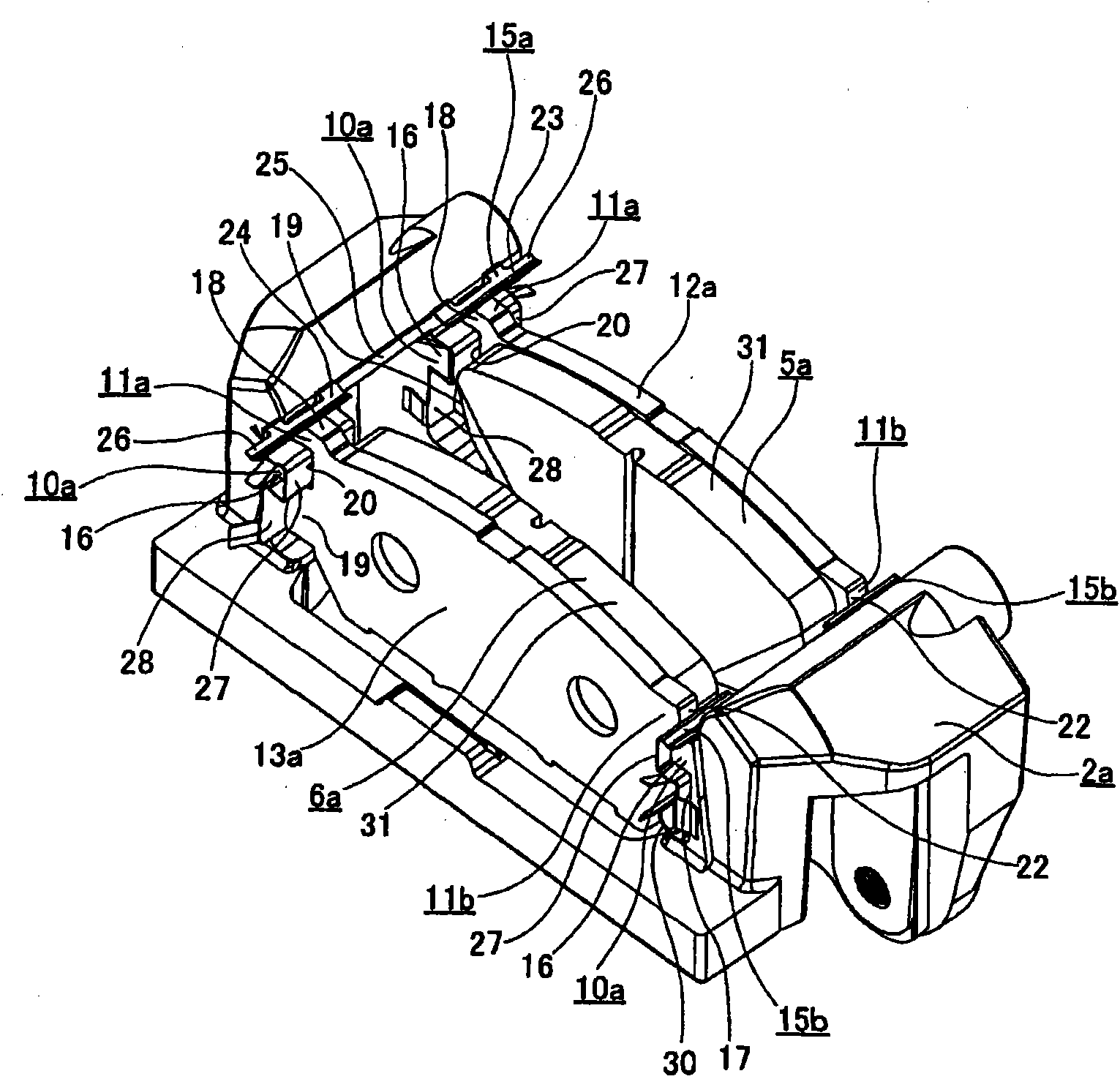

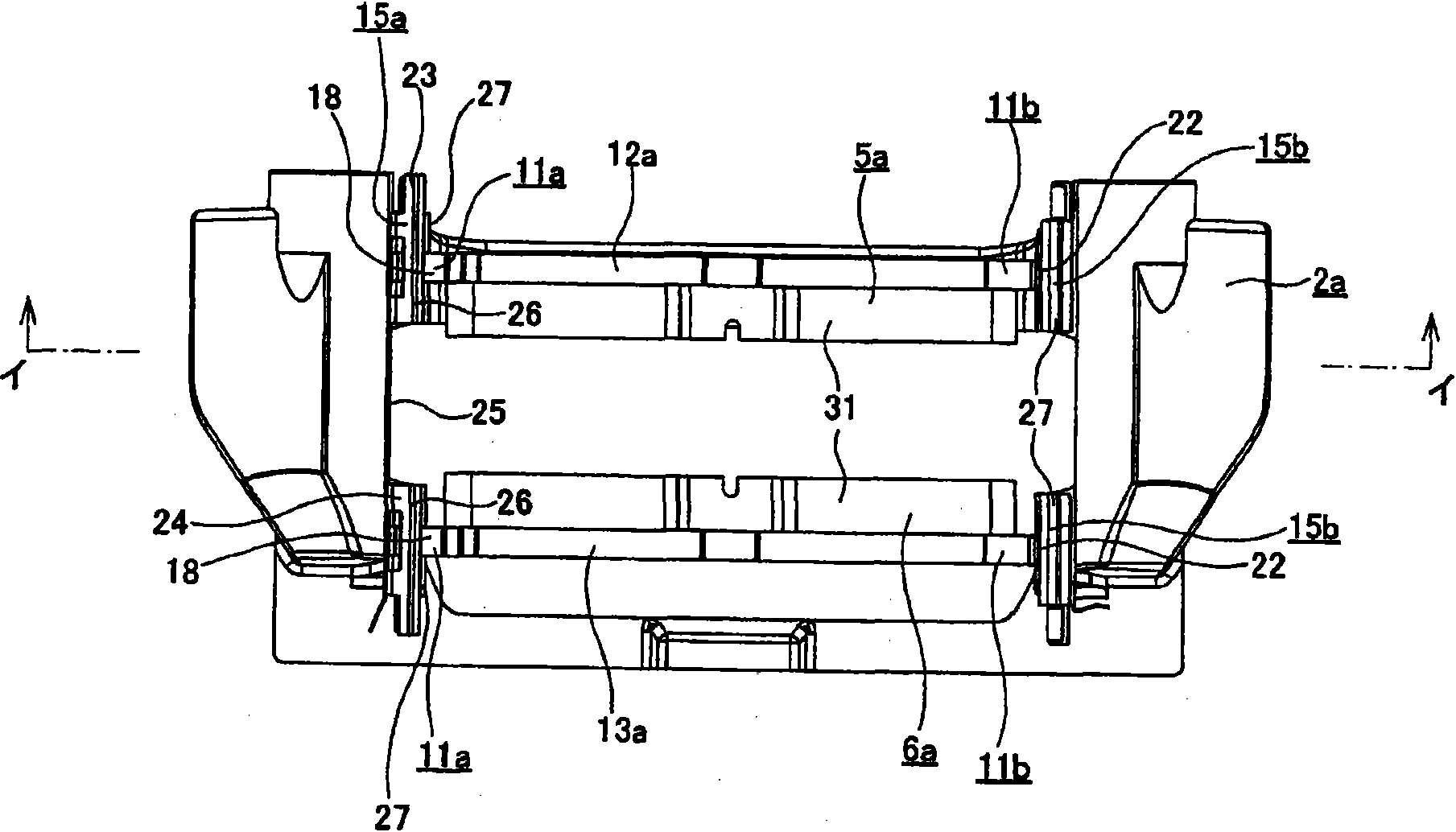

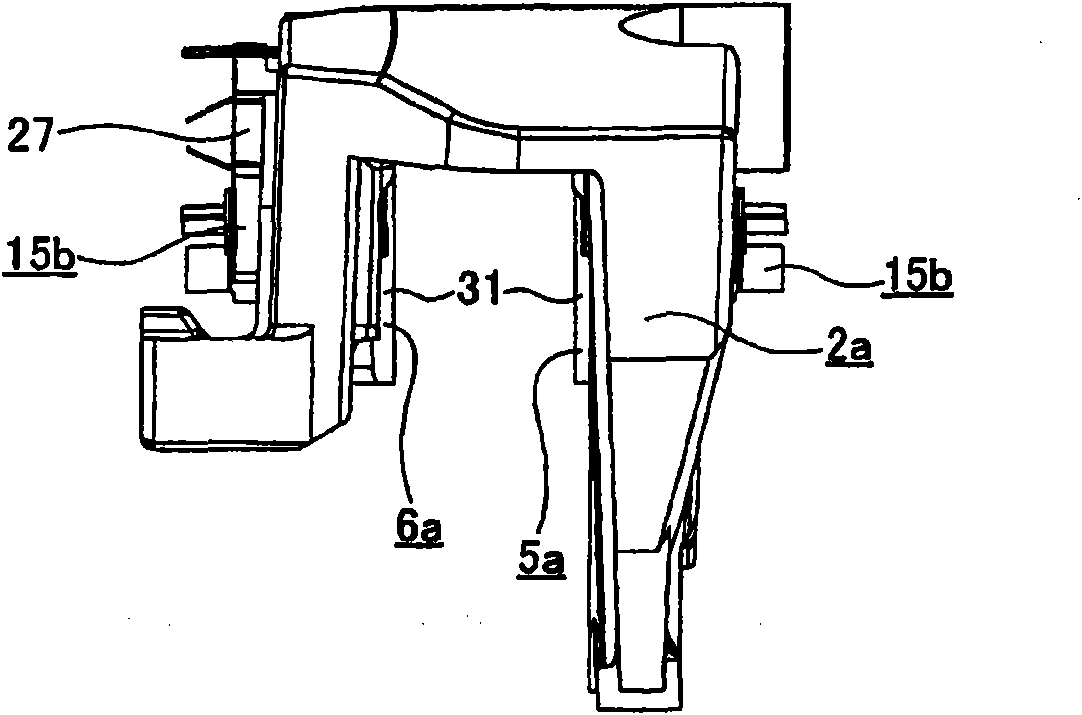

[0074] Figure 1~6 An example of the embodiment of the present invention is shown. In addition, this example is characterized in that in order to stabilize the shape of the inner and outer pads 5a, 6a, and to reduce the pull and vibration (noise, chatter) of each pad 5a, 6a, each The structure of the portion where the pads 5a, 6a are supported by the bracket 2a, the structure of the pad clips 15a, 15b, etc. have been improved. Regarding the structure and function of other parts, for example because of the Figure 7-11 The shown conventional structures are the same, so illustrations and descriptions related to the same parts are omitted or simplified, and the characteristic parts of this example will be mainly described below.

[0075] In the case of this example, the rotor 1 (refer to Figure 7-9 ) on both sides of the rotor 1 in the circumferential direction, are respectively formed with holder-side engaging portions 10a, 10a. In addition, pad-side engaging portions 11a, 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com