Rotating device having single ball bearing

A ball bearing, rotating device technology, applied in parts of pumping devices for elastic fluids, machines/engines, liquid fuel engines, etc., can solve problems such as power wastage, not well solved, and voids, etc. To solve the effect of vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

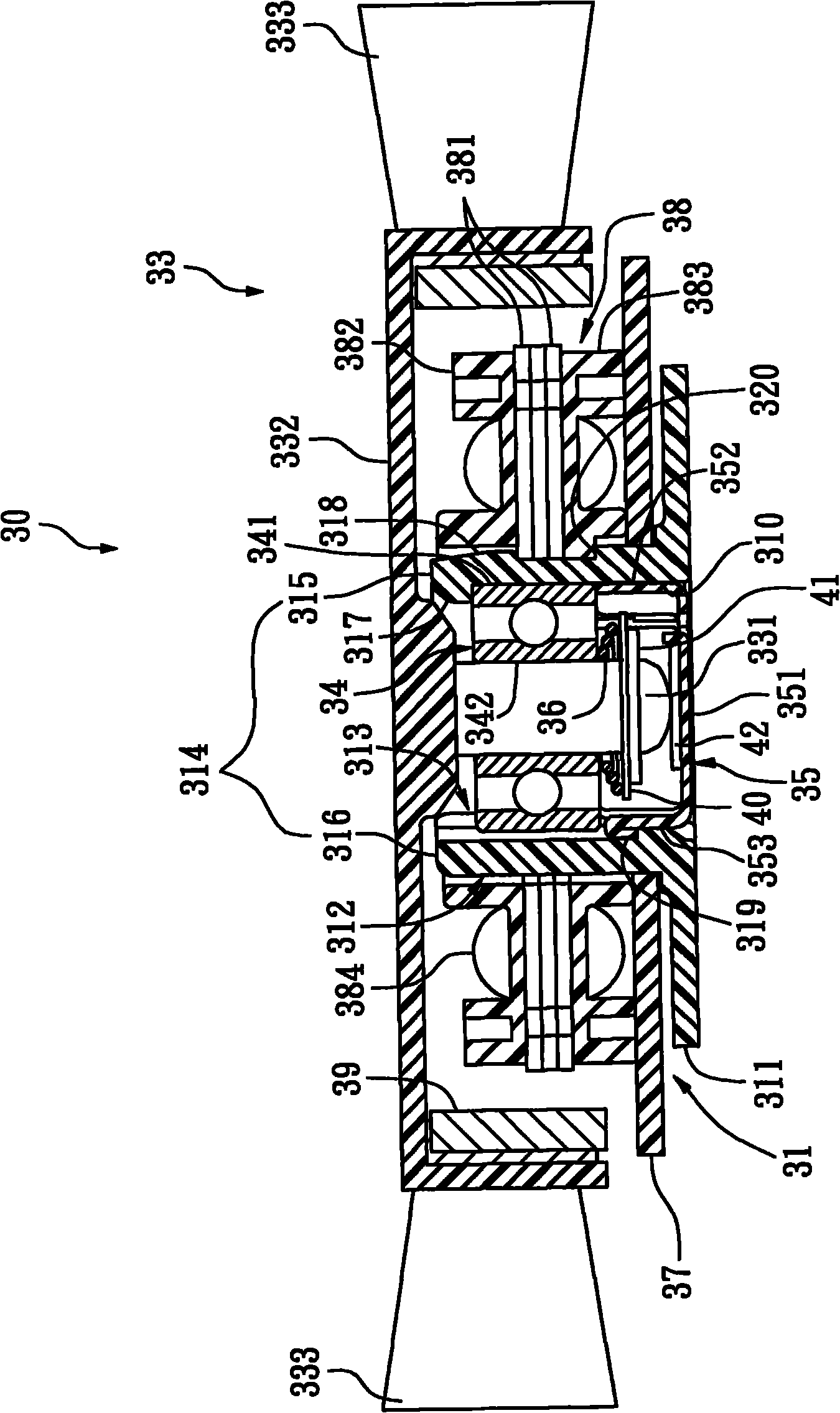

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. Before the present invention is described in detail, it is noted that in the following description, similar elements are denoted by the same numerals.

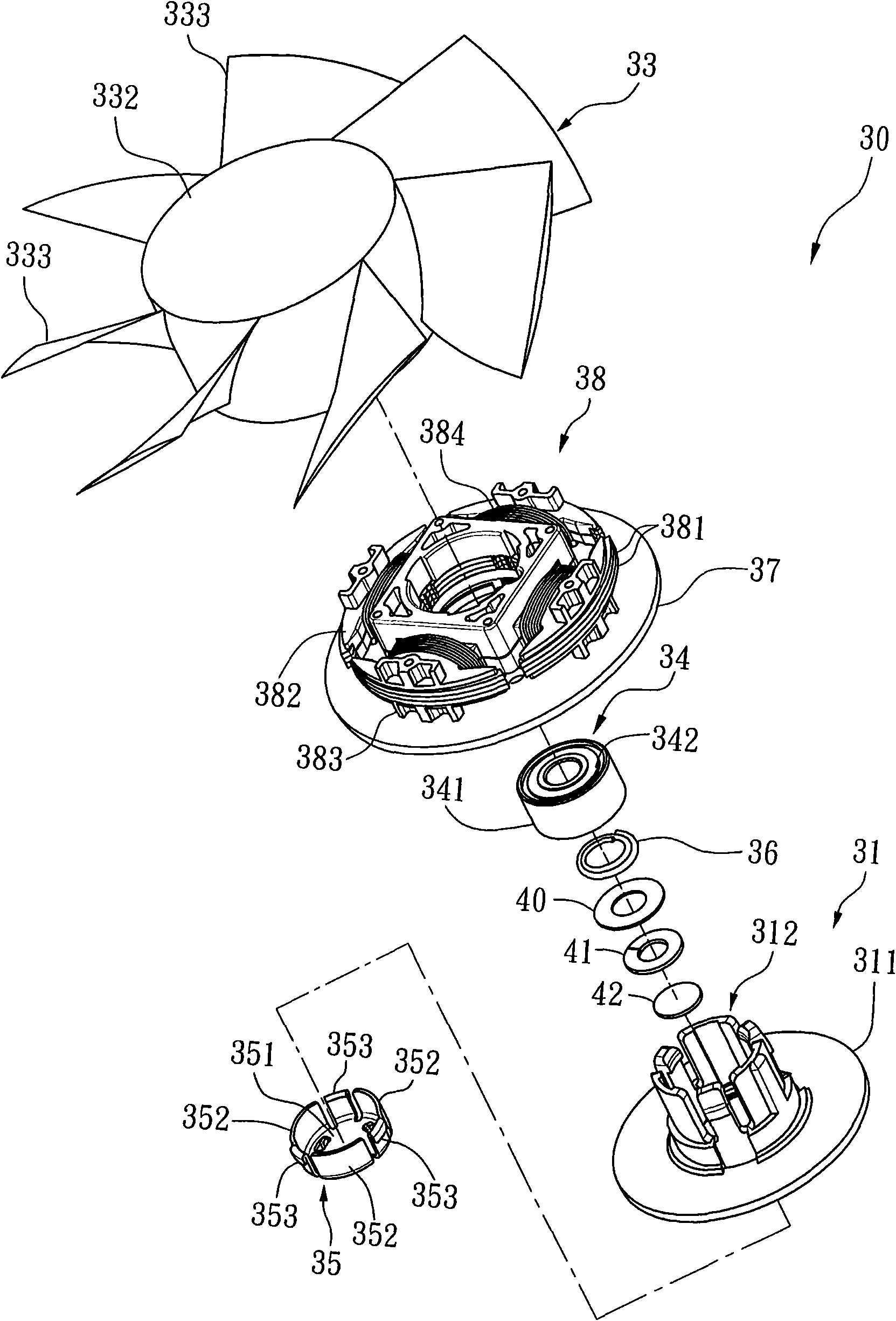

[0027] refer to figure 2 , image 3 , the first preferred embodiment of the rotating device 30 with a single ball bearing of the present invention comprises a base 31, a rotor unit 33 pivotally arranged on the base 31, a ball used to support the smooth rotation of the rotor unit 33 Bearing 34, a sleeve 35 that is engaged with the base 31 and is used to abut against the ball bearing 34, and an elastic member 36 that is used to prestress the ball bearing 34, the base 31 has a limit A ring wall 311 with a perforation 310, and a shaft tube 312 integrally extended from the ring wall 311, the perforation 310 is only seen in the image 3 .

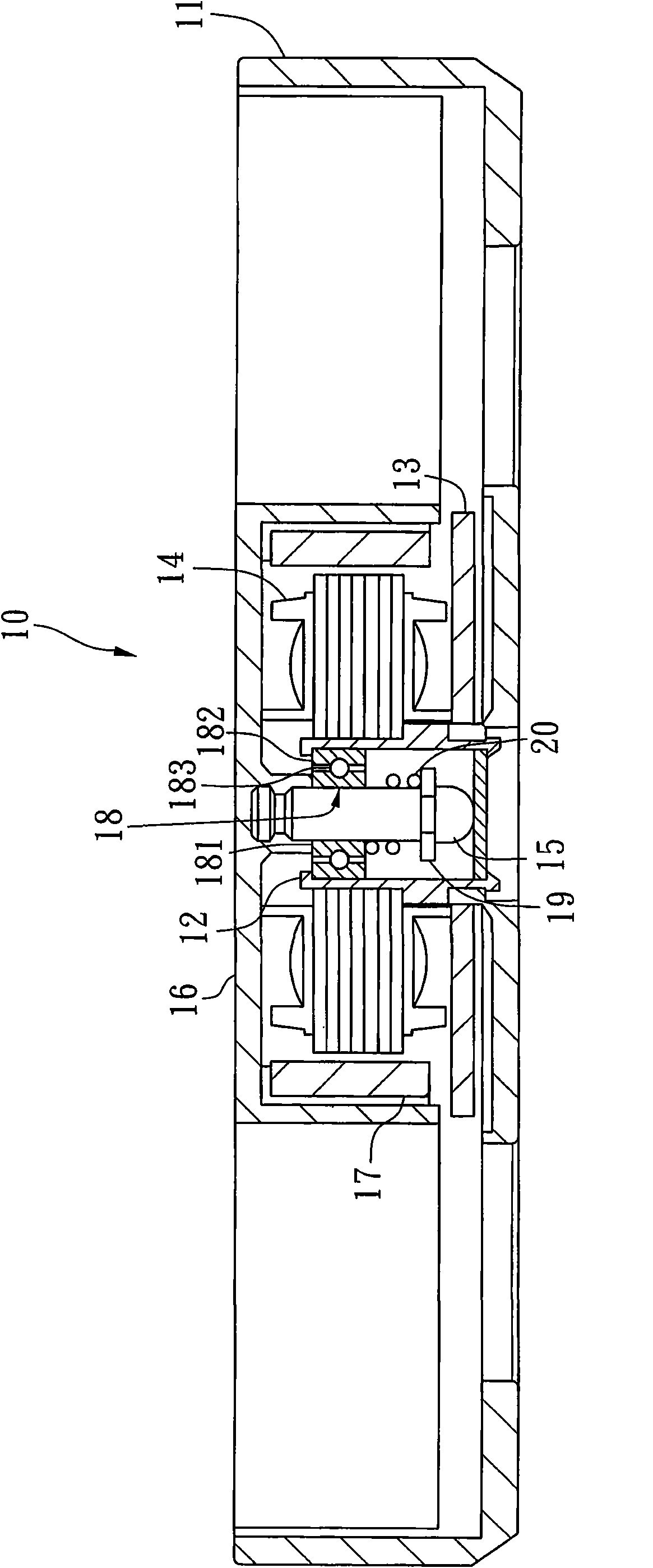

[0028] And because this rotating device 30 is mainly applied in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com