Automatic gauge control (AGC) method for rolling mill

A control method and rolling mill technology, applied in the direction of rolling force/roll gap control, etc., can solve the problems that cannot completely eliminate the thickness deviation of the exit strip, time lag, etc., to facilitate self-learning optimization, eliminate time lag, and enhance reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

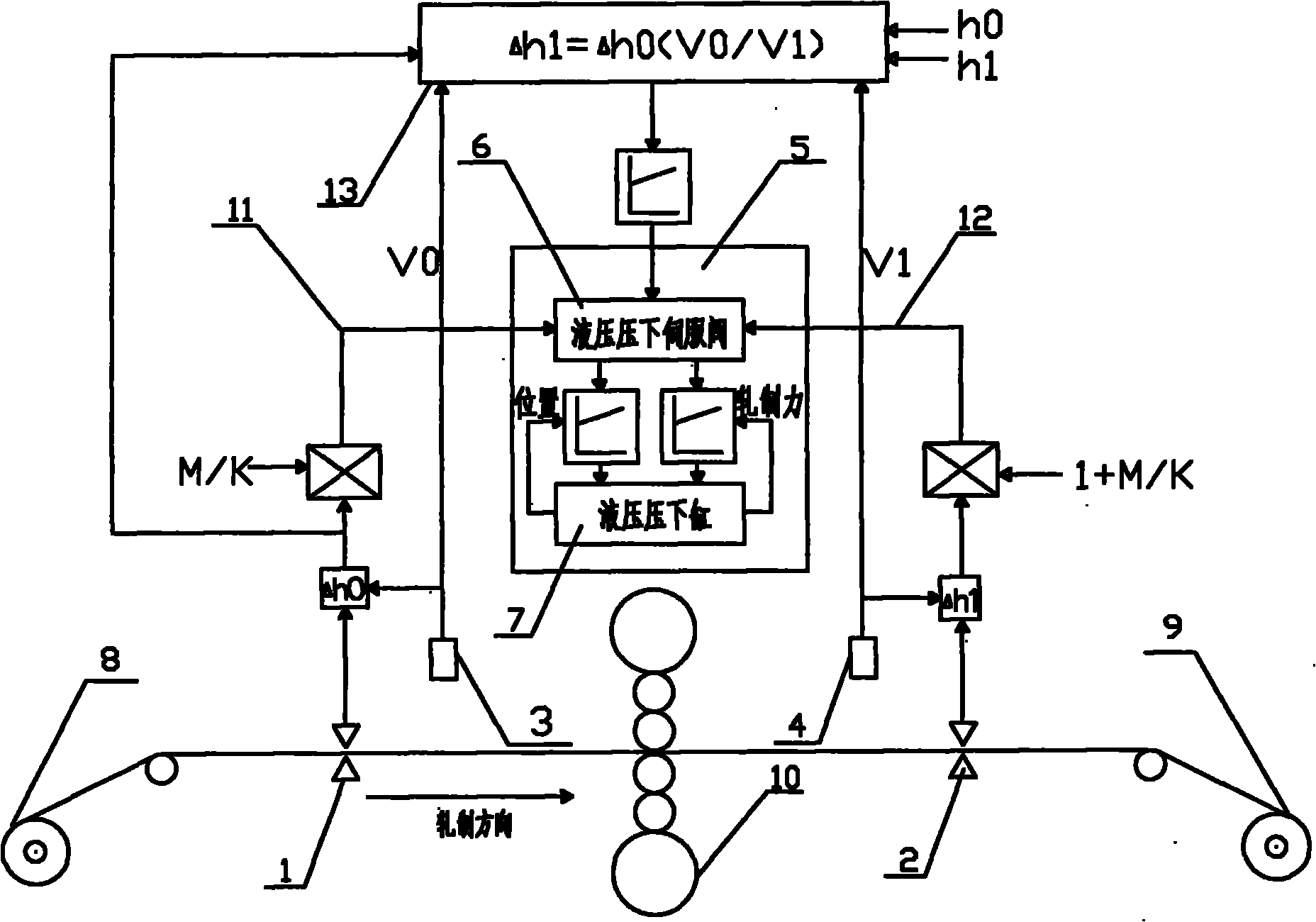

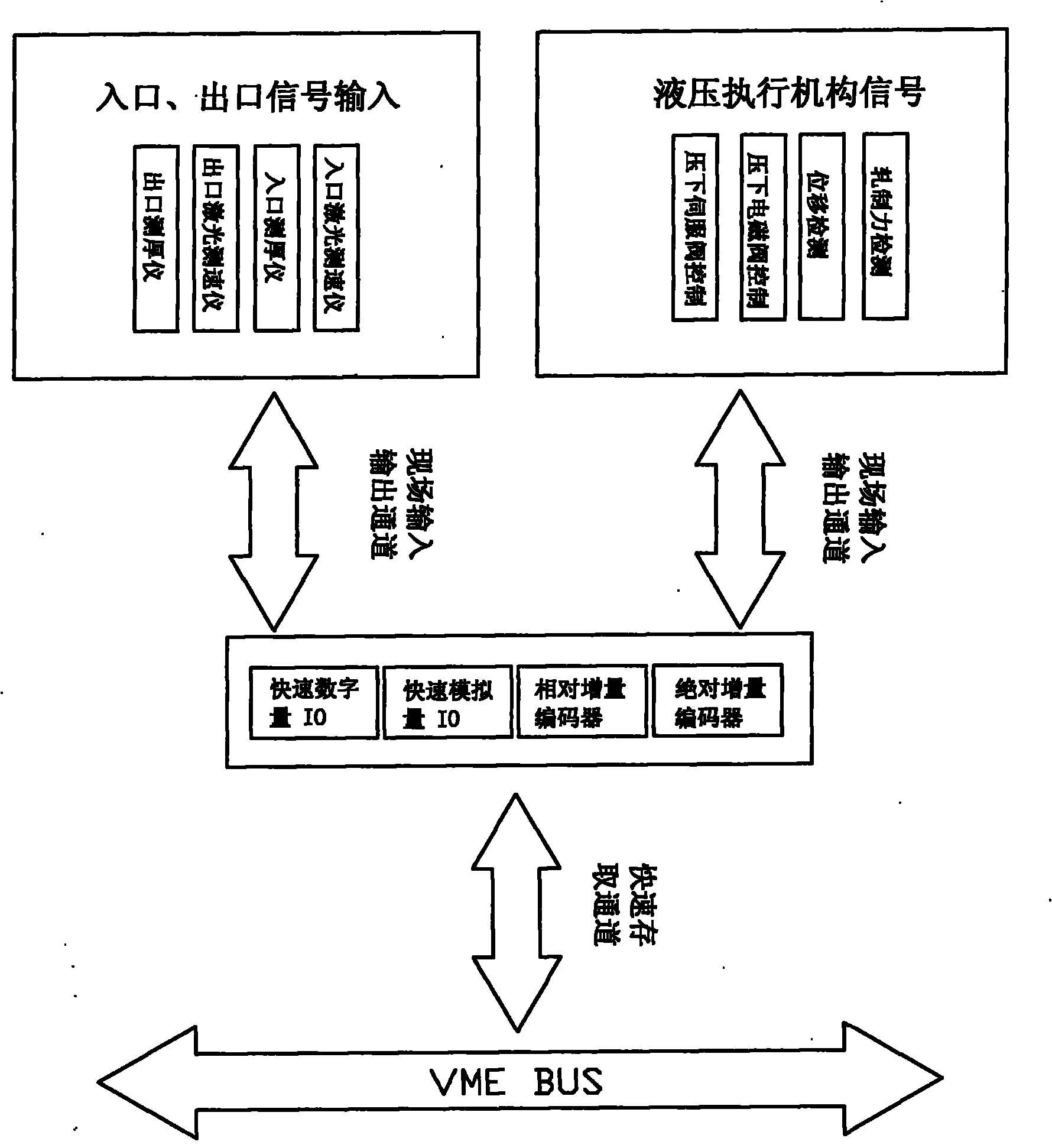

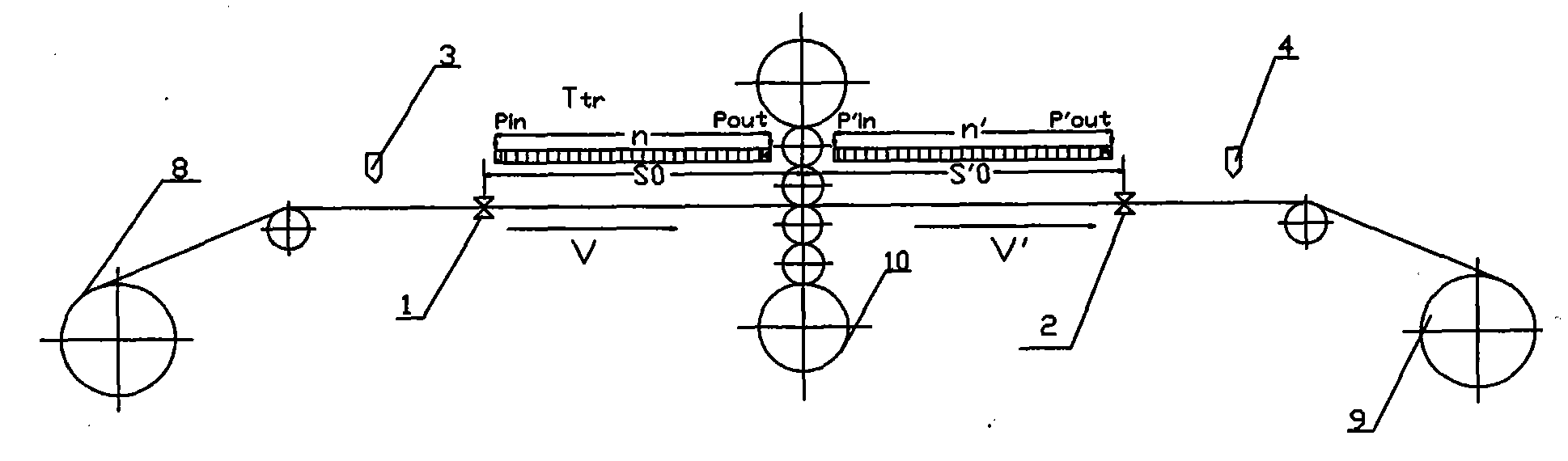

[0029] The invention relates to a method for AGC feedforward, second flow and feedback control of a rolling mill. The common point of these three control methods is to achieve the purpose of controlling the exit thickness of the rolling mill by changing the set value of the roll gap that the rolling mill presses down. Among them, the feedforward control and the second flow control both control the outlet thickness by sampling and measuring the inlet thickness and tracking it to the position of the roll gap of the rolling mill, and then modify the setting value of the pressed roll gap according to the algorithm; the feedback control requires the outlet thickness gauge The measured value is traced back to the position of the rolling mill, and then the value of the rolled gap is corrected according to the feedback control algorithm to control the exit thickness of the strip.

[0030] The present invention combines the above three control methods, and achieves the purpose of high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com