Transmission mechanism of fruit and vegetable cleaning machine

A technology of transmission mechanism and purifier, which is applied in application, food processing, food science, etc., can solve the problems of simple washing methods, single types of washing, and low efficiency, and achieve high washing efficiency, saving water resources, and various washing methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

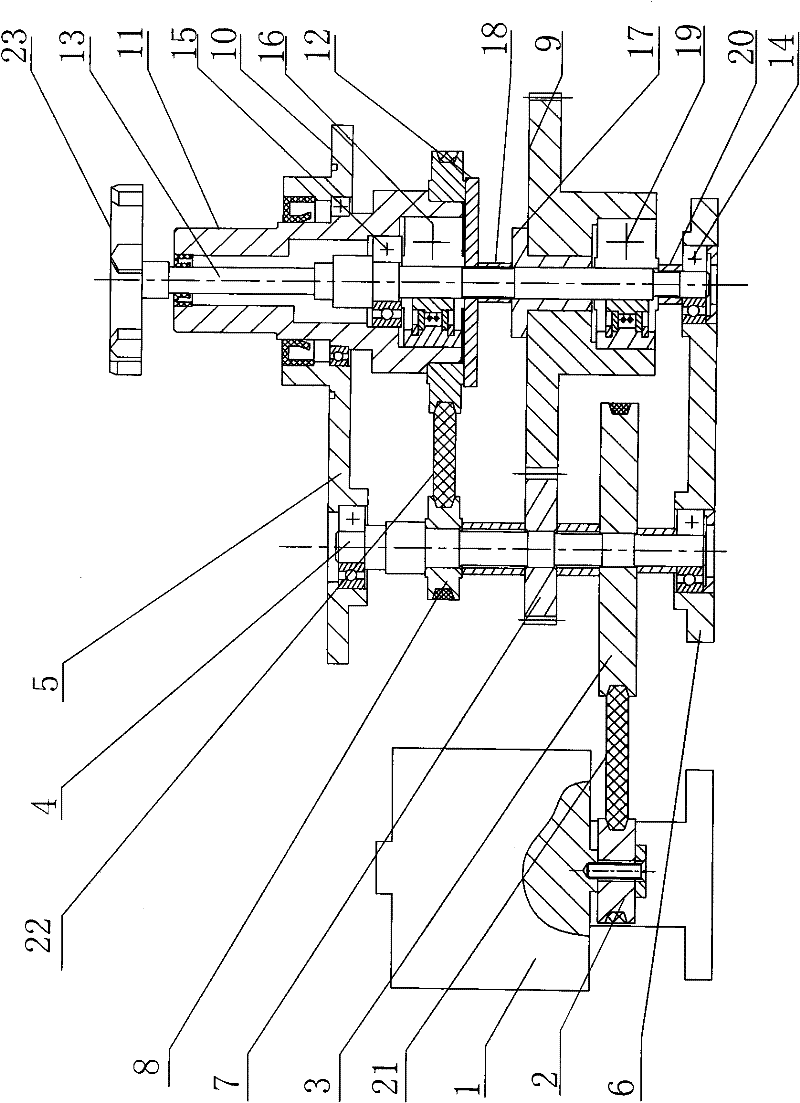

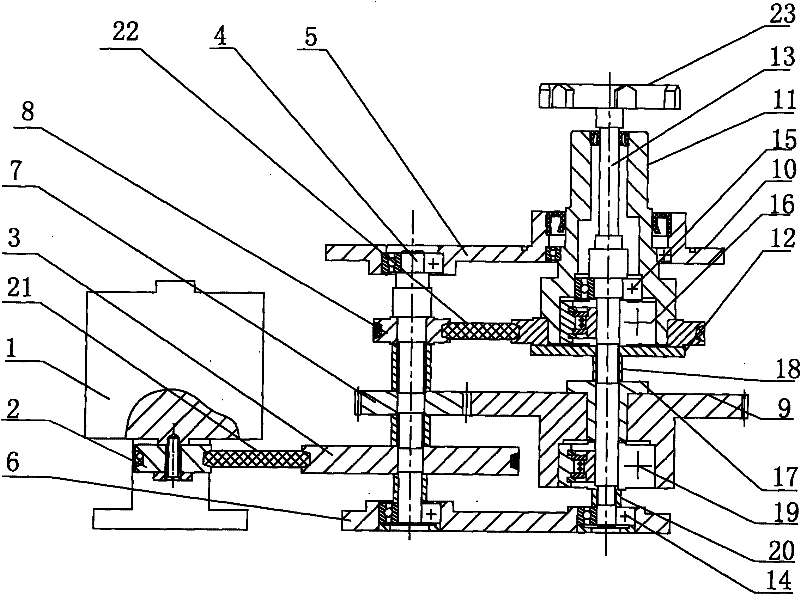

[0007] Specific implementation mode one: combine figure 1 Describe this embodiment, the transmission mechanism of this embodiment includes a motor 1, a first pulley 2, a second pulley 3, a first transmission shaft 4, an upper support plate 5, a lower support plate 6, a first gear 7, a third Pulley 8, second gear 9, fourth pulley 10, hollow shaft 11, retaining ring 12, solid shaft 13, first bearing 14, second bearing 15, first overrunning clutch 16, flange bearing 17, first The shaft sleeve 18, the second overrunning clutch 19, the second shaft sleeve 20, the first conveyor belt 21 and the second conveyor belt 22, the output shaft of the motor 1 is connected to the first pulley 2, and the first pulley 2 is connected to the The second pulley 3 is connected by transmission through the first conveyor belt 21, and the two ends of the first transmission shaft 4 are respectively connected to the upper support plate 5 and the lower support plate 6 in rotation, and the first transmissi...

specific Embodiment approach 2

[0008] Specific implementation mode two: combination figure 1 To illustrate this embodiment, the transmission mechanism of this embodiment also includes a washing basket bottom engaging plate 23, which is fixed on the solid shaft 13 and is located outside the hollow shaft 11. This structure is used to install the vegetable basket . Other components and connections are the same as those in the first embodiment.

[0009] Working principle: (when in use, the impeller is installed on the hollow shaft 11, and the vegetable basket is installed on the meshing plate 23 at the bottom of the washing basket), the motor 1 rotates forward to drive the first pulley 2 and the second pulley 3 to move, thereby driving the first drive The shaft 4 rotates, the first transmission shaft 4 drives the third pulley 8 and the fourth pulley 10 to move, the first overrunning clutch 16 engages, the second overrunning clutch 19 disengages, and the fourth pulley 10 simultaneously drives the hollow shaft 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com