Light focusing cavity of laser

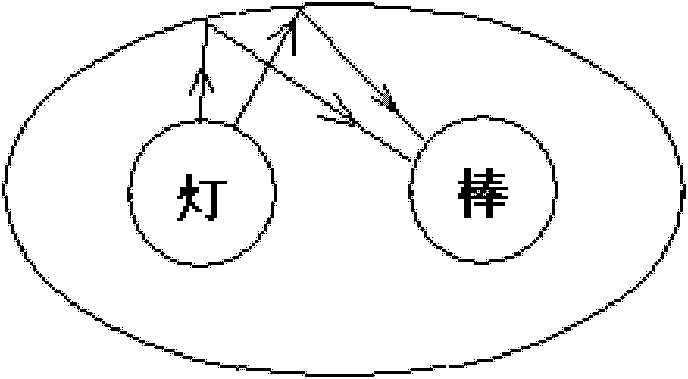

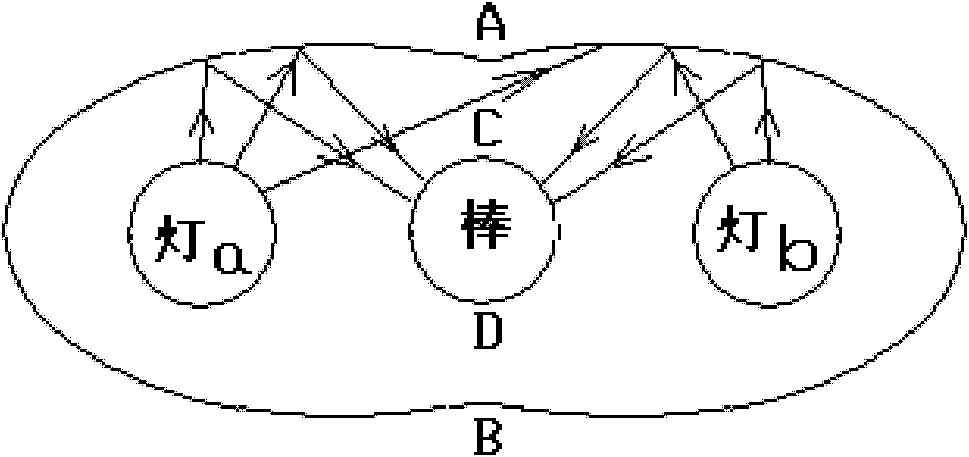

A condensing cavity and laser technology, which is applied in lasers, laser parts, phonon exciters, etc., can solve the problem of low efficiency of concentrating cavity and achieve the effect of high concentrating efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

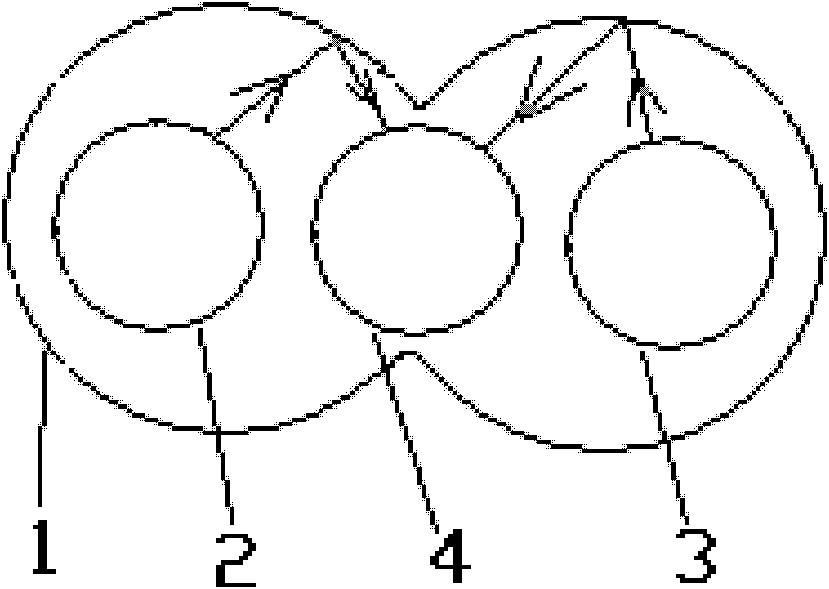

[0019] Such as image 3 As shown, the concentrating cavity provided by the present invention includes a concentrating cavity body 1, a YAG rod 4 and two lamps 2, 3; the shape of the concentrating cavity body 1 is formed by two intersecting cylindrical surfaces, and the two intersecting cylindrical surfaces Symmetrically arranged, and their axes are parallel, the cross-section radii of the two intersecting cylindrical surfaces are equal, both are 15-35mm; side, and symmetrically distributed. The axes of the focusing cavity 1, the YAG rod 4 and the two lamps 2 and 3 are all parallel. The two lamps 2, 3 can be xenon lamps or helium lamps.

[0020] This new type of concentrating cavity is fundamentally different from the double elliptical cylindrical concentrating cavity, and also different from the general intersecting cylindrical concentrating cavity. It is a tightly wrapped intersecting circular concentrating cavity with elliptical properties.

[0021] The radius of the inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com