Touch control module and sensing device

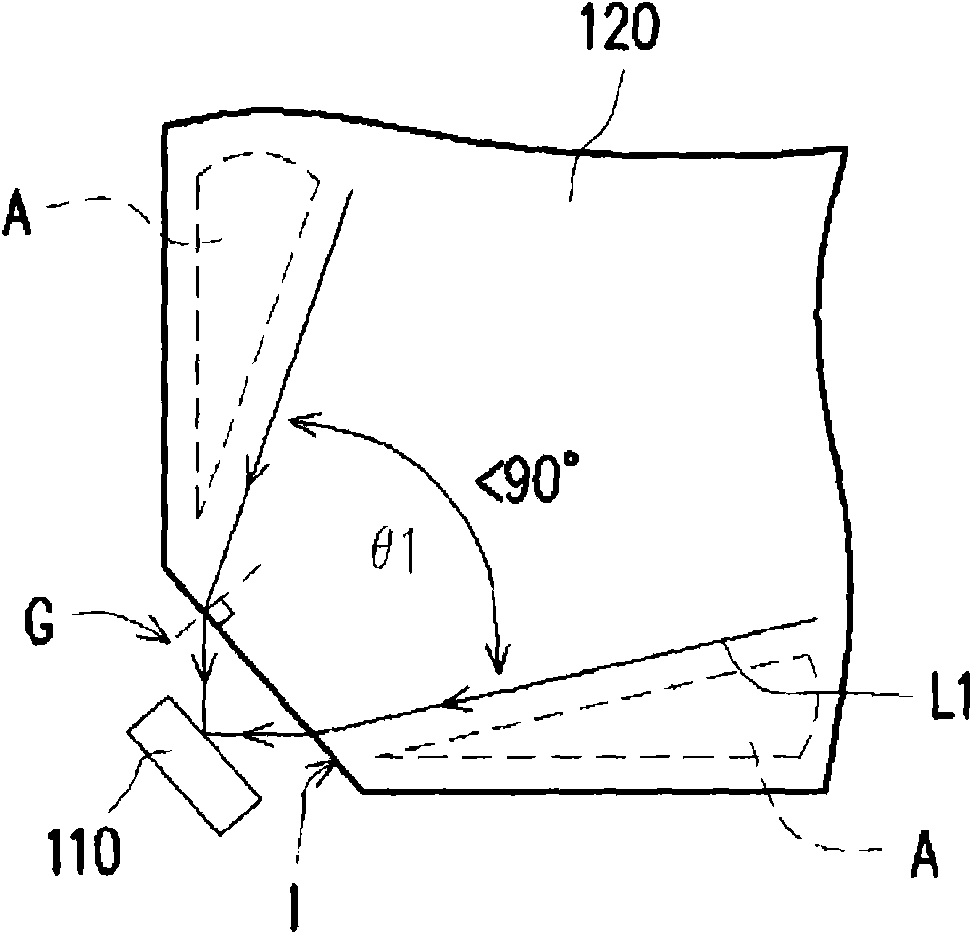

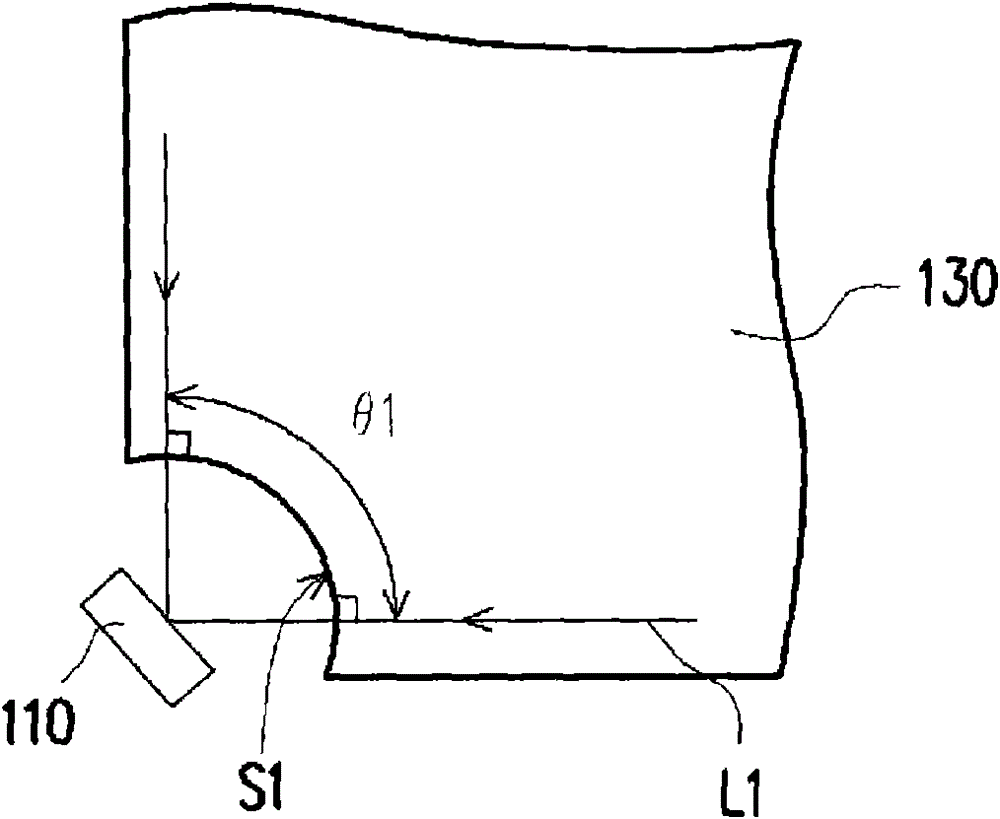

A technology of a touch module and a sensing device, which is applied in the directions of instruments, electrical digital data processing, and data processing input/output processes, etc., can solve the problems of poor alignment accuracy between the plug-in module 110 and the light guide plate 130, and achieves Effect of increasing sensing acuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

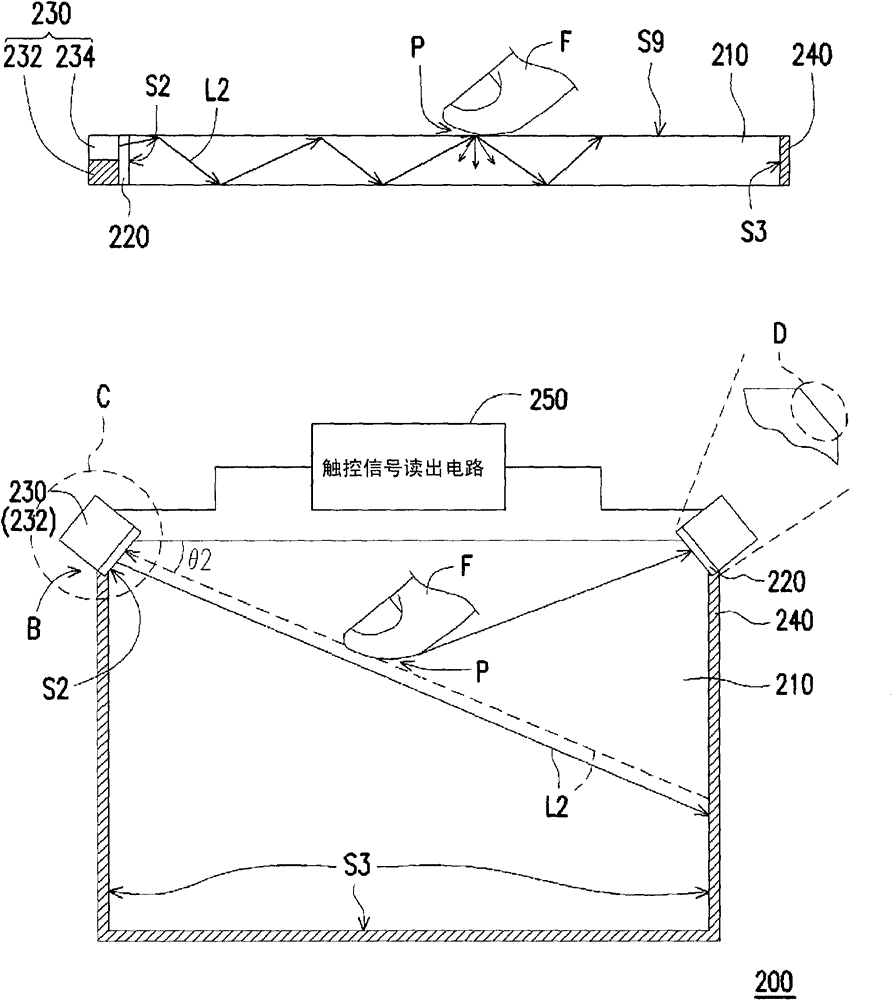

[0068] figure 2 It is a schematic diagram of a touch module (touch module) according to the first embodiment of the present invention, wherein figure 2 The top of is the cross-sectional view of the touch module, while figure 2 Below is the top view of the touch module. Please refer to figure 2The touch module 200 of this embodiment includes a light guide plate 210 , an optical glue 220 , a touch sensing module 230 and a retro-reflector 240 . The light guide plate 210 has an end surface S2 and a plurality of optical surfaces S3. The touch sensing module 230 is disposed on the end surface S2 , and the touch sensing module 230 includes a sensing component 232 and a light source 234 . In addition, the light guide plate 210 further has a top surface S9, and the end surface S2 and the optical surface S3 are substantially perpendicular to the top surface S9. Additionally, if figure 2 As shown below, the end surface S2 is an inclined plane. In detail, the end surface S2 of...

no. 2 example

[0077] Figure 5 It is a schematic diagram of a touch module according to the second embodiment of the present invention, wherein Figure 5 The top of is the cross-sectional view of the touch module, while Figure 5 Below is the top view of the touch module. Please refer to Figure 5 , the touch module 400 of this embodiment and figure 2 The touch module 200 is similar, but the main difference between the two is: the touch module 400 does not use figure 2 Instead, the light source 234' is directly disposed on the optical surface S3, wherein the light source 234' is a plurality of light bars.

[0078] Such as Figure 5 As shown, the light source 234' is adapted to provide light L2 into the light guide plate 210, and the sensing element 232' is adapted to receive the light L2 transmitted through the light guide plate 210. When the user touches the light guide plate 210 with a finger F or a stylus, the light L2 near the touch point P will be scattered, and the above-menti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com