Captive ball quick-release joint structure

A joint structure and tethered ball technology, applied in cable joints, fiber mechanical structures, etc., can solve the problems of high production cost, difficult maintenance, and optical cables are easily twisted, and achieve the effect of simple structure and low manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

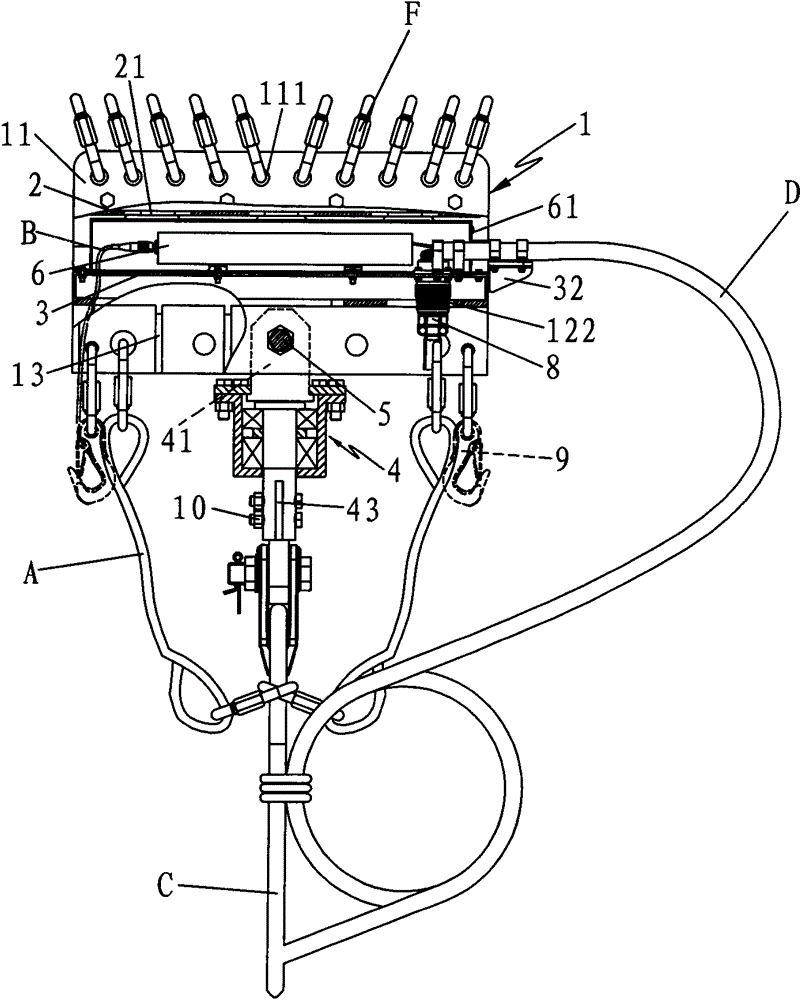

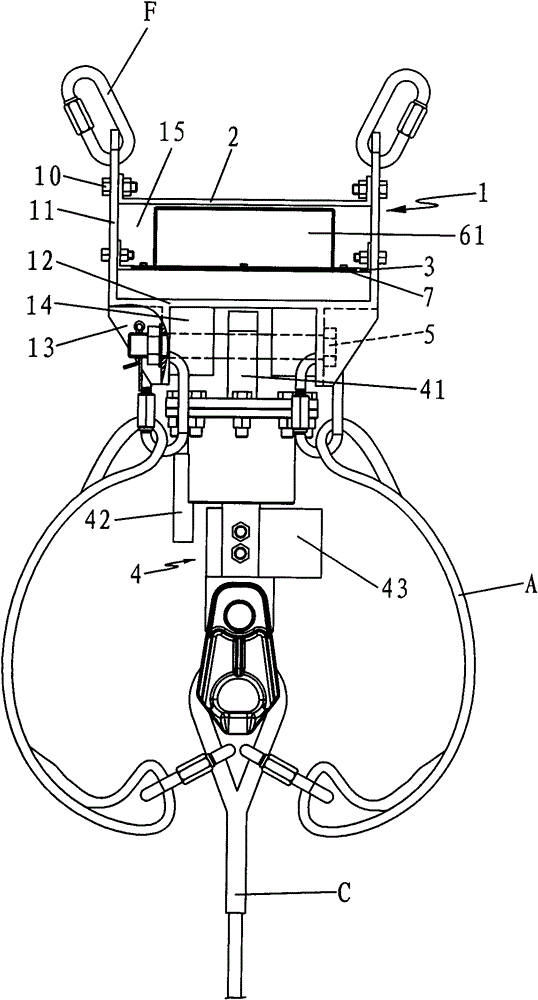

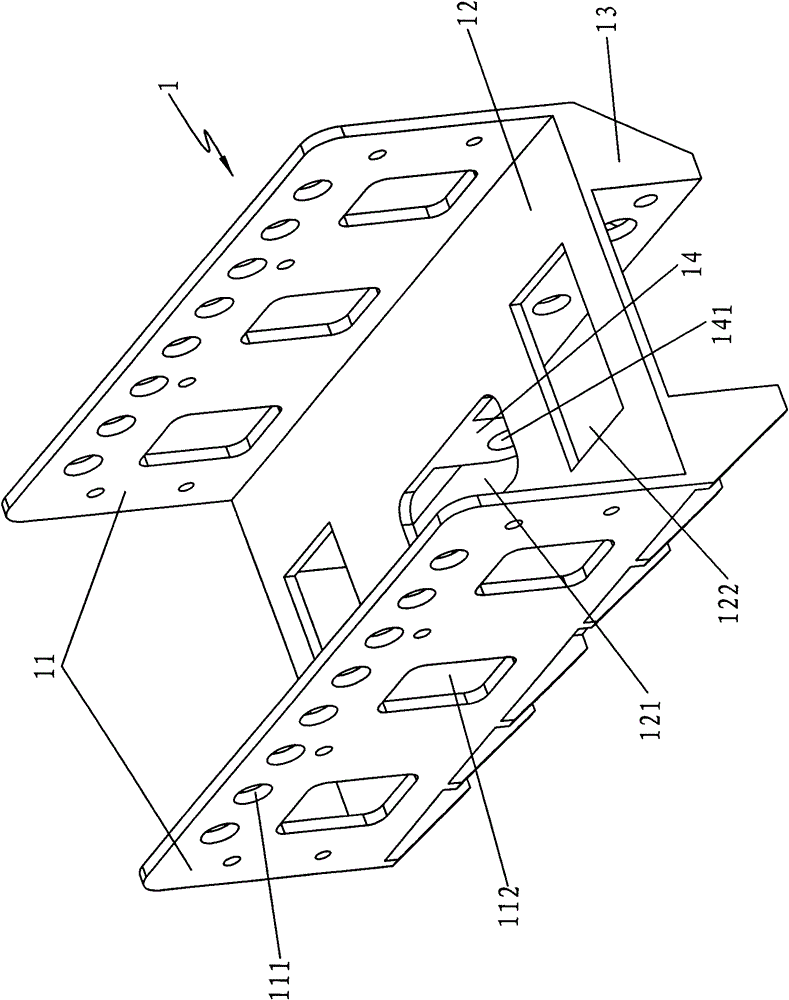

[0039] like Figure 1 to Figure 2 As shown, the present invention mainly includes a quick-release joint steel structure frame 1, a fixing plate 2, an installation plate 3, and an adapter 4, wherein the fixing plate 2 and the installation plate 3 are connected to the quick-release joint steel structure frame by bolts 10 1 On the side plate 11 of the upper half, the height difference between the two plates forms an accommodating space 15; an optical fiber end box 6 is arranged in the accommodating space 15, and an optical fiber plug and connector are arranged on the optical fiber end box 6 Line B, the optical fiber optical end box 6 is provided with a waterproof cover 61, the waterproof cover 61 is fixed on the mounting plate 3 by bolts 10, and is waterproofed with a rubber gasket 7; A support plate 14 is provided, and the support plate 14 is connected with the connection plate 41 of the adapter 4 through the cotter pin 5. The adapter 4 is provided with a bearing seat limit plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com