System and method for diagnosing leakage of pressure-bearing pipe of boiler

A diagnostic system and pressure-bearing pipe technology, applied in directions such as measuring the rate of increase and deceleration of the fluid, detecting the appearance of the fluid at the leakage point, and testing the tightness of the fluid by using an electrical device, can solve leakage alarm signals, leakage detection systems, System delays and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following description is merely exemplary in nature and is not intended to limit the invention, its application or uses. Those skilled in the art can understand that, without changing the basic principle of the technical solution of the present invention, various modifications and variations of the structure of the present invention and / or its component parts can be made, and these modifications and variations Will fall within the protection scope of the present invention.

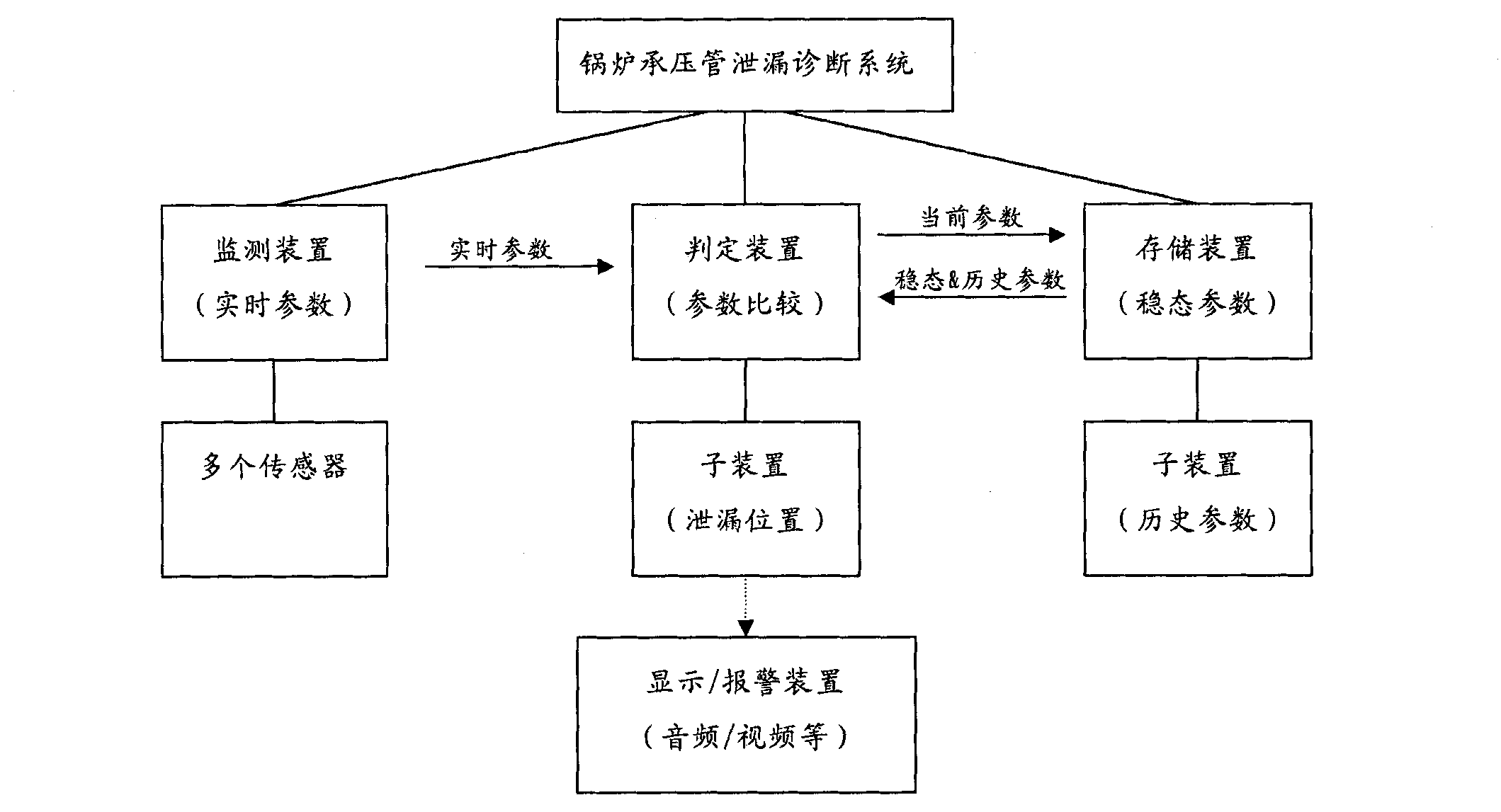

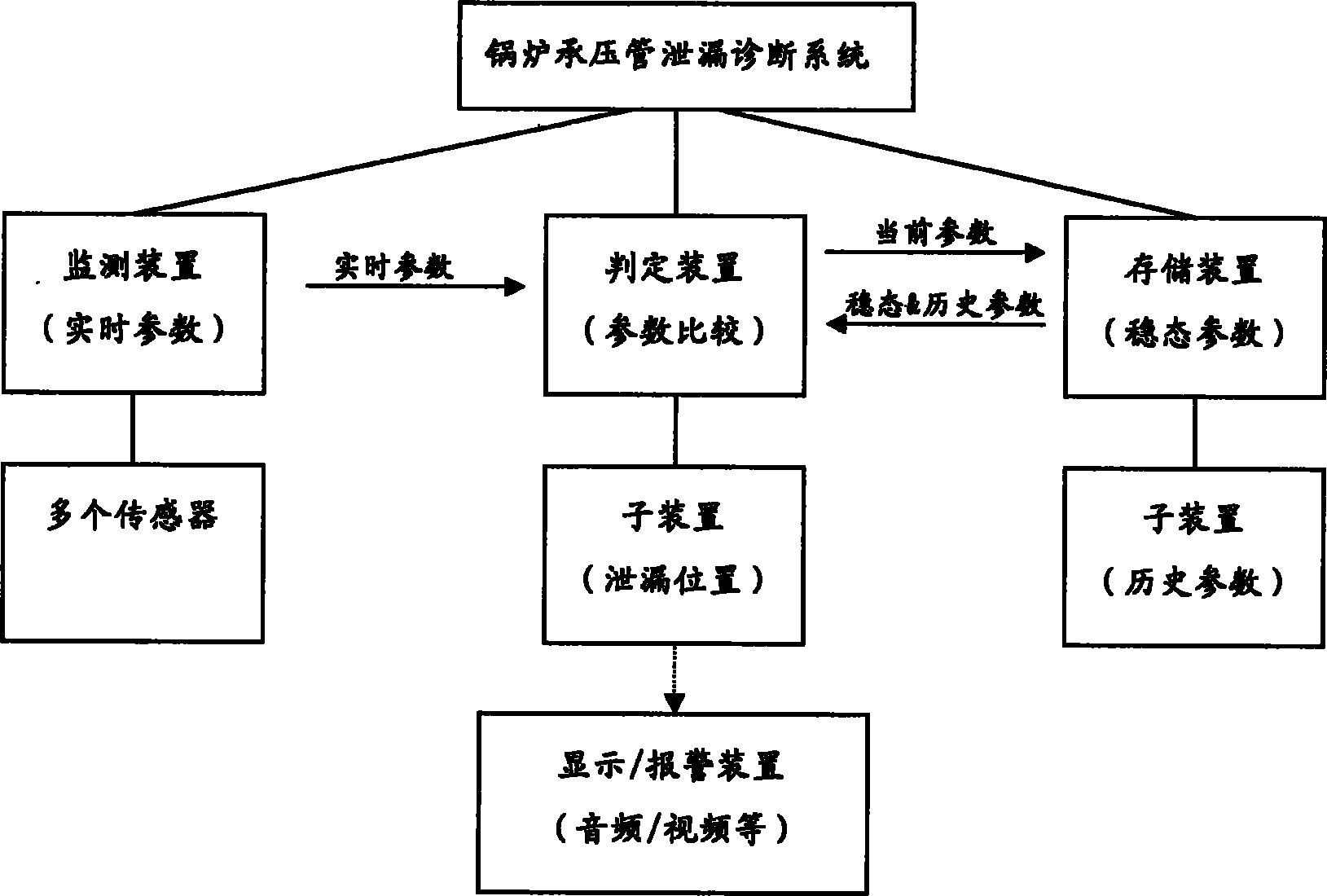

[0020] The core technology of the boiler pressure tube leakage intelligent diagnosis system of the present invention lies in the organic combination of neural network and expert system, adopts neuron fuzzy control theory, utilizes self-learning function, associative memory function and distributed processing information function based on neural network, utilizes Using the information retention of the network to complete imprecise diagnostic reasoning can better simulate expert experience and int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com